The Essentials of Textile Packaging for Global Trade

: Textile Packaging for Global Trade,Abstract:,Textiles, as a vital component of global trade, require specialized packaging to ensure their safety, integrity, and longevity during transportation. This paper discusses the essentials of textile packaging for international trade, including proper labeling, protective materials, and appropriate handling methods. It emphasizes the importance of using durable and leak-proof packaging to prevent damage during transit. The paper also highlights the need for standardization and harmonization of textile packaging regulations to facilitate seamless trade between different countries. By understanding these essentials, traders can minimize risks and improve the overall efficiency of their textile supply chains.

Introduction: Textile goods are among the most valuable commodities on the global market. They require careful packaging to ensure their safety during transit, minimize damage during storage, and enhance brand recognition. This guide aims to provide a comprehensive overview of the essential textile packaging requirements that businesses must adhere to for successful international trade.

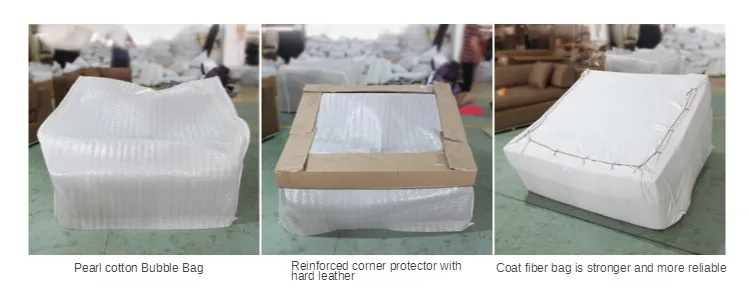

Packaging Materials: The primary materials used in textile packaging include cardboard boxes, plastic wraps, bubble wrap, foam inserts, and polystyrene foam. Each material has its unique advantages and disadvantages, and selecting the right one depends on the specific needs of the product and the intended destination.

Cardboard Boxes: Cardboard boxes are the most common type of packaging for textiles due to their strength, durability, and affordability. They can be customized with labels and graphics to enhance brand identity. However, cardboard is not as protective as other materials, so it's crucial to use additional cushioning materials like foam or plastic wrap.

Plastic Wraps: Plastic wrap is an effective barrier against moisture and dust, making it ideal for protecting delicate textiles. It's also easy to clean and reuse. However, plastic wrap may not be as durable as cardboard and can be heavier than other materials.

Bubble Wrap: Bubble wrap provides excellent cushioning and protection against shocks and vibrations. It's ideal for fragile textiles like woven fabrics or printed textiles. However, bubble wrap is bulky and can be difficult to handle, especially when stacked.

Foam Inserts: Foam inserts are designed to absorb shock and provide extra cushioning. They are particularly useful for textiles that need to be shipped in large quantities or over long distances. However, foam inserts can be expensive and may not be suitable for all products.

Polystyrene Foam: Polystyrene foam is a popular choice for packaging textiles due to its lightweight and flexibility. It's easy to mold and can be customized with graphics or colors. However, polystyrene foam may not be as protective as other materials and can deform over time.

Packaging Design: The design of the packaging should reflect the value and quality of the textiles being shipped. It should also comply with regulations set by relevant authorities such as FDA (United States), FCC (United States), and EU (Europe). Some key aspects to consider include:

-

Packaging Size: The size of the package must accommodate the weight and dimensions of the textiles without causing damage or excessive weight.

-

Packaging Shape: The shape of the package should be optimized for transportation and storage. For example, round packages are easier to stack and transport, while square packages are more stable.

-

Packaging Color: Color can be used to differentiate between different products or brands. However, it's important to avoid using bright colors that can attract attention from potential thieves or cause damage during transport.

-

Packaging Labeling: Labels should be clearly marked with the name, address, phone number, and any relevant information about the product. Additionally, labels should be waterproof and resistant to UV light.

-

Packaging Safety: The packaging should prevent damage during transit, such as crushing or bending. It should also protect the textiles from moisture, dust, and insects.

-

Packaging Recyclability: Recyclable packaging is becoming increasingly popular as consumers become more environmentally conscious. Companies should consider using biodegradable or recyclable materials in their packaging to reduce waste and promote sustainability.

Case Study: Consider the case of a textile company that ships high-value silk scarves internationally. To ensure they meet the strict packaging requirements of the United States Customs and Border Protection (CBP), they decided to use a combination of cardboard boxes, plastic wrap, and foam inserts. The scarves were carefully wrapped in plastic wrap to protect them from moisture and dust, then placed inside cardboard boxes lined with additional foam inserts for added cushioning. Finally, the boxes were sealed with strong tape to prevent damage during shipping. By following these guidelines, the company was able to successfully ship thousands of scarves without any issues, earning a positive reputation for their exceptional packaging practices.

Conclusion: Textile packaging plays a crucial role in ensuring the safe, secure, and timely delivery of textiles. Companies must select the right materials and design their packaging according to the specific needs of their products and the intended destination. By following industry standards and regulations, they can create packaging that meets the expectations of both customers and regulatory bodies. In summary, textile packaging is an essential aspect of successful international trade, and companies that prioritize quality and compliance will reap the rewards of a loyal customer base and a positive reputation in the marketplace.

随着现代生活水平的提高,纺织品作为日常生活中的必需品,其包装质量越来越受到消费者的关注,本文将围绕纺织品包装的要求展开讨论,并通过案例分析来说明其重要性。

纺织品包装的基本要求

安全性

纺织品包装必须具备高度的安全性,确保在运输过程中不会对人员或环境造成伤害,包装材料应符合相关安全标准,无毒无害,不易燃易爆。

环保性

纺织品包装应注重环保性,采用可降解、可回收的材料,减少环境污染,包装设计应考虑减少废弃物产生,提高资源利用率。

美观性

纺织品包装应具有美观性,能够提升产品的整体形象,包装外观应与产品特性相匹配,能够体现产品的风格和特点。

实用性

纺织品包装应具有实用性,能够满足产品的实际需求,包装结构应合理,便于运输和存储,包装尺寸和重量也应符合实际需求。

纺织品包装案例分析

某品牌丝绸服装的包装设计

该品牌丝绸服装采用环保材料制作,包装采用透明塑料袋搭配丝绸布料制成的手提袋,手提袋设计简约大方,色彩柔和,给人一种优雅的感觉,包装上印有品牌标志和产品信息,便于消费者了解产品特性,该包装不仅具有安全性、环保性,还具有美观性,体现了品牌的形象和风格。

某品牌棉质衣物的高端定制包装

该品牌为高端客户定制了棉质衣物的高端包装,采用高级纸板材料制作,外观精美,手感舒适,包装内还配备了防潮防湿袋、温度调节器等辅助材料,确保衣物在运输过程中得到充分的保护,该包装不仅注重安全性、环保性,还注重实用性,能够满足客户对高品质产品的需求。

纺织品包装的具体要求补充说明

尺寸和重量要求

纺织品包装的尺寸和重量应符合实际需求,对于大型纺织品,如丝绸服装等,需要确保包装结构稳定、不易破损,对于小型纺织品,如内衣、袜子等,需要确保包装轻便、便于携带,对于不同材质的纺织品,其重量和尺寸也有所不同,需要根据实际需求进行选择。

防潮防湿要求

纺织品在运输过程中容易受潮、发霉,因此需要采取相应的防潮防湿措施,对于防水性能较好的材料,可以采用防水袋或防水膜等材料进行包装,在包装设计中也应考虑防潮防湿的需求,避免产品在潮湿环境下受损。

标识要求

纺织品包装上应清晰标注产品名称、生产厂家、生产日期等信息,对于特殊产品或敏感产品,还需要标注相关的安全标识和警示语,标识应清晰易读、易于识别,以便消费者了解产品特性和使用注意事项。

纺织品作为日常生活中必不可少的物品,其包装质量直接影响到消费者的购买体验和使用效果,纺织品包装的要求必须严格把控,在具体实施过程中,需要综合考虑安全性、环保性、美观性、实用性等多个方面,还需要根据实际需求进行选择和调整,以确保纺织品包装的质量和效果达到最佳状态。

Articles related to the knowledge points of this article:

The Evolution and Impact of Textiles in Global Commerce

Nurturing Quality:The Journey of Nantong Baowei Textiles

Where to Explore Textile Certifications

The Art of Interior Textiles:Crafting a Masterpiece in the Canvas

The Fabric of Innovation:A Look at Wenzhou Huanhong Textiles