Understanding the Standards and Techniques for Textile amp;Footwear Testing

In the realm of textile and footwear testing, there is a clear understanding of what constitutes acceptable standards and techniques. The process involves rigorous evaluations that ensure the quality and durability of products. These evaluations are essential to meet consumer needs and industry expectations.,One of the critical aspects of textile and footwear testing is ensuring that products meet the necessary standards for wearability, comfort, and functionality. This includes evaluating materials used in manufacturing, such as fabrics and synthetic fibers, as well as examining the overall design, construction, and fit of products.,Furthermore, testing methods must be accurate and reliable, providing data that can help manufacturers make informed decisions about product improvement and development. Techniques such as tensile testing, compression testing, tear resistance testing, and wear resistance testing are all crucial components of this process.,In conclusion, textile and footwear testing is an important aspect of the industry, ensuring that products meet high standards and meet the needs of both consumers and industry professionals. By following established guidelines and using appropriate testing techniques, manufacturers can produce products that are not only functional but also durable and comfortable for their users.

Introduction Textile and footwear industries are essential to our daily lives. They provide comfort, functionality, style, and sustainability. To meet consumer demands, manufacturers need to adhere to stringent quality standards and regulatory requirements. This includes testing methods that ensure products are safe, durable, and free from harmful materials. In this guide, we'll explore some of the most critical textile and footwear testing methods.

Material Testing

-

Strictness and Compression Resistance: Fabrics must be able to withstand pressure without breaking or losing shape. For instance, in a standard compression test, samples are compressed using weights to measure their resistance. A high level of compression resistance indicates a fabric is strong and suitable for use in high-stress environments such as sportswear and military uniforms.

-

Tear Strength and Tenacity: Fabrics should resist tearing when tested under specific conditions, ensuring they can hold together during wear. A tear strength test involves pulling threads apart at a specified speed. High tear strength ensures fabrics will not easily tear, making them ideal for everyday wear.

-

Stability and Durability: Textiles must be stable enough to maintain their shape even after repeated washing and wearing. The durability test measures how long a fabric will last before deteriorating. It's often measured by measuring the weight loss over time.

-

Moisture Resistance: Textiles need to be moisture-resistant to prevent mold growth and bacterial growth. Moisture absorption tests determine how quickly fabrics absorb water. Good results mean fabrics are suitable for outdoor wear and sports equipment.

-

Flammability: Textiles must not ignite easily when exposed to flames, especially in situations like fire safety or emergency response. The flammability test measures the time it takes for a fabric to burn. Fast burning times indicate higher risk of catching fire, so these fabrics are typically used in hazardous environments.

Footwear Testing

-

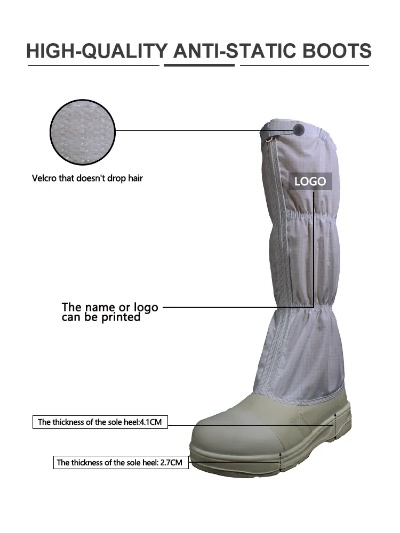

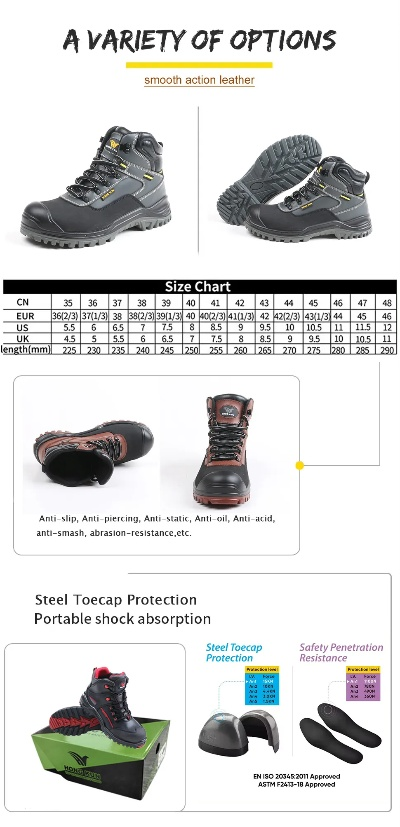

Shoe Fitting and Structural Stability: Footwear needs to fit properly and remain structurally sound to provide adequate support and protection. An example of this is a shoe's heel-to-toe measurement, which shows the distance from the heel to the front edge of the shoe.

-

Material Comfort and Durability: Footwear should feel comfortable on the feet and provide adequate support while wearing. A comfort test involves wearing the shoes under different conditions, such as walking or standing, to measure discomfort levels. Additionally, durability tests measure how long a shoe will last through regular wear and tear.

-

Safety and Health Standards: Footwear should comply with safety regulations and protect against hazards like sharp edges or chemical exposure. For instance, a shoe's sole design should avoid cuts or other injuries caused by sharp points.

-

Environmental Impact: Footwear companies must consider how their products affect the environment. Sustainable footwear testing evaluates the eco-friendliness of materials used and manufacturing processes to reduce waste and promote recycling.

-

Epidemiological Risk Assessment: Footwear testing should include an assessment of potential risks to public health. For example, if a shoe contains harmful substances like lead or cadmium, it must be labeled and avoided by consumers.

Case Studies

-

Nike Air Max 1: Nike's iconic sneaker was rigorously tested for material composition and performance. The shoe's cushioning system was designed to provide maximum energy return, making it suitable for basketball, tennis, and other high-intensity activities.

-

Adidas Ultraboost: Adidas' Ultraboost running shoes were tested for their stability and durability during long-distance running. These shoes were designed specifically for athletes who need to endure intense physical demands without compromising comfort or safety.

Conclusion Textile and footwear testing is crucial for maintaining product quality and customer safety. Companies must follow established testing protocols and industry guidelines to produce safe, reliable, and ethically sourced products. By understanding these methods thoroughly, manufacturers can better meet the needs of consumers and stay ahead in the competitive market.

大家好,今天我们将探讨纺织品及鞋类的检测方法,随着人们对生活品质的追求不断提高,纺织品和鞋类的质量成为了消费者关注的焦点,为了确保产品的质量和安全性,对纺织品及鞋类的检测方法提出了更高的要求,下面我们将详细介绍相关的检测方法和案例。

纺织品检测方法

纤维含量检测

纤维含量是衡量纺织品质量的重要指标之一,在纺织品检测中,可以采用各种检测方法,如纤维分析仪、显微镜观察等,通过纤维分析仪可以快速准确地检测出纤维的种类、含量等参数,显微镜观察可以直观地观察纤维的形态、结构等特征。

化学成分检测

纺织品中可能含有多种化学成分,如染料、助剂等,在纺织品检测中,可以采用各种化学分析方法,如色谱分析、质谱分析等,对纺织品中的化学成分进行定量和定性分析,这些方法可以有效地检测出纺织品中的有害物质和污染物,确保产品的安全性和环保性。

物理性能检测

纺织品除了要满足化学成分的要求外,还需要满足一定的物理性能要求,在物理性能检测中,可以采用各种测试仪器和方法,如拉伸试验机、耐磨试验机等,通过这些测试仪器和方法可以检测出纺织品的强度、耐磨性、抗皱性等物理性能指标,这些指标是衡量纺织品使用舒适度和耐用性的重要参数。

鞋类检测方法

材料检测

鞋类材料的选择直接关系到产品的质量和安全性,在鞋类检测中,可以采用各种检测方法,如材料分析仪、显微镜观察等,通过材料分析仪可以快速准确地检测出鞋类的材料类型、材质等参数,显微镜观察可以直观地观察鞋类的外观、结构等特征。

功能性测试

鞋类作为日常穿着的物品,其功能性也是消费者关注的重点之一,在鞋类检测中,可以进行各种功能性测试,如步行舒适性测试、防滑性能测试等,这些测试可以有效地评估鞋类的舒适度、防滑性能等性能指标,确保产品的使用效果和安全性。

案例说明

以某品牌的一款纺织品为例,其检测方法和案例如下:

该品牌的一款纺织品采用了高品质的纤维材料,经过严格的检测流程,确保了产品的质量和安全性,在纤维含量检测中,采用了纤维分析仪进行快速准确的检测,结果显示该款纺织品的纤维含量符合国家标准要求,在化学成分检测中,采用了色谱分析和质谱分析等方法,有效地检测出了纺织品中的有害物质和污染物,确保了产品的安全性和环保性,在物理性能检测中,采用了拉伸试验机和耐磨试验机等测试仪器和方法,测试结果显示该款纺织品的强度、耐磨性等物理性能指标符合行业标准要求,该品牌还进行了其他功能性测试,如步行舒适性测试和防滑性能测试等,结果显示该款鞋类具有良好的舒适度和防滑性能。

纺织品及鞋类的检测方法对于保证产品的质量和安全性至关重要,在纺织品检测中,可以采用各种检测方法,包括纤维含量检测、化学成分检测和物理性能检测等,在鞋类检测中,也需要关注材料的选用和功能性测试等方面,在实际操作中,还需要根据具体情况选择合适的检测方法和案例进行说明,通过不断改进和提高纺织品及鞋类的检测方法和技术水平,可以更好地保障消费者的权益和健康安全。

Articles related to the knowledge points of this article:

A Comprehensive Look into the Different Kinds of Fibre-Picking Devices

Embracing the Future:The Innovative Services in Yixing Textiles

The Booming Fashion of Textiles This Year An Overview