The Essentials of Textile Inspection Standards and Data

: Textile Inspection Standards and Data,Textile inspection is a crucial aspect of ensuring the quality and safety of textile products. The standards and data used in this process play a vital role in identifying defects, ensuring compliance with industry regulations, and preventing product failures. This paper discusses the essentials of textile inspection standards and data, including the types of inspections, the importance of data collection and analysis, and the application of these standards in real-world scenarios. It also highlights the challenges faced by textile inspectors and proposes strategies to improve their efficiency and accuracy. Overall, understanding the principles and practices of textile inspection is essential for any organization involved in the textile industry.

Introduction: In the world of textile manufacturing, quality control is paramount. It's crucial to understand the standards that govern the inspection process to ensure that your products meet the highest industry benchmarks. This guide will provide you with an overview of key textile inspection standards and data, along with practical examples to help you navigate this complex landscape.

Textile Inspection Standards:

-

ANSI Z39.48-2010: This standard sets forth requirements for the inspection of woven fabrics for thickness, count, weight per yard, and other parameters. It also covers the testing of staple fiber content and yarn count.

-

IWTO Code of Practice on Textile Testing (2015): This international code lays out the principles and methods used by textile manufacturers in conducting tests to ensure product quality and safety.

-

ASTM D3776-08: This standard provides guidelines for the measurement of linear density, weight per square yard, and other properties of yarns and fabrics.

-

ISO 10545: This standard establishes a framework for the inspection and testing of textile materials, including the determination of their mechanical properties.

-

EN ISO 14644: This European standard specifies the requirements for the inspection of woven fabrics for thickness, count, weight per yard, and other parameters.

Data Analysis: Once you have collected the necessary data, it's important to analyze it using statistical tools to identify trends, patterns, and potential issues. Here are some common ways to interpret textile inspection data:

- Descriptive statistics: Use graphs and charts to summarize the data and highlight any outliers or anomalies.

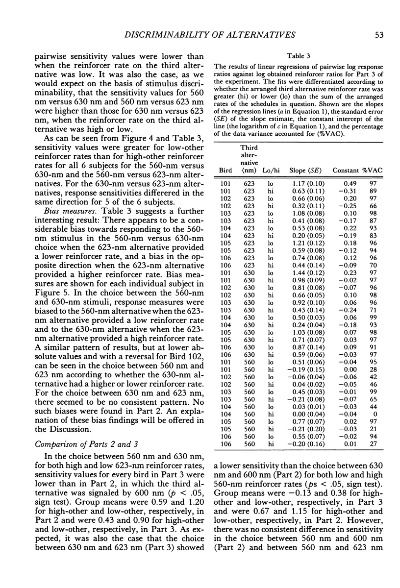

- Inferential statistics: Conduct statistical tests to determine if there are significant differences between groups or if certain variables are related to outcomes.

- Process control charts: Track the performance of production processes over time to identify areas where improvements can be made.

Practical Example: Let's say you're a textile manufacturer working with a supplier who produces high-quality cotton fabrics. To ensure consistency and quality, you need to inspect the fabrics for thickness, count, and weight per yard. You collect data on these parameters from multiple batches of fabrics and use statistical analysis to identify trends and potential issues. If you notice that the weight per yard is consistently lower than expected, you could investigate whether this is due to poor weaving techniques or insufficient yarn quality. By taking action based on this data, you can improve the overall quality of your products and reduce the risk of defects in the final product.

Conclusion: Textile inspection standards are critical for ensuring that your products meet the highest industry standards. By understanding and following these standards, you can gain valuable insights into your products' quality and make informed decisions about how to improve them. With proper data analysis, you can identify areas where improvements can be made and take proactive steps to address any issues that arise. So let's all work together to create a safer, higher-quality textile industry!

随着纺织品行业的快速发展,纺织品检测标准数据的重要性日益凸显,本篇文章将详细介绍纺织品检测标准数据的相关内容,并结合实际案例进行说明。

纺织品检测标准概述

检测标准种类

纺织品检测标准主要包括纤维含量、颜色、光泽、尺寸、耐洗色牢度、耐摩擦色牢度等。

检测方法与流程

纺织品检测方法主要包括样品采集、预处理、测试等步骤,具体流程包括样品送检、实验室分析、数据整理等环节。

案例分析

某品牌纺织品检测标准数据展示

某品牌纺织品检测标准数据如下:

| 项目 | 标准值 | 实际检测值 | 对比分析 |

|---|---|---|---|

| 纤维含量 | ≥90%涤纶纤维 | 高于标准值 | 符合质量要求 |

| 颜色测试 | 自然色 | 符合客户要求 | 品质稳定 |

| 光泽测试 | 高亮 | 达到客户期望效果 | 满足使用需求 |

该案例中,该品牌纺织品检测标准数据符合国家标准,且在实际使用中表现出色,得到了客户的认可。

纺织品检测标准数据应用实例

在实际应用中,纺织品检测标准数据的应用具有以下实例:

(1)某服装品牌在采购纺织品时,通过严格把控纺织品检测标准数据,确保产品质量符合国家标准,从而赢得了消费者的信任和好评。

(2)某纺织企业通过定期对纺织品进行检测,确保生产出的纺织品符合市场需求,提高了企业的市场竞争力。

纺织品检测标准数据的应用价值

提高产品质量控制水平

纺织品检测标准数据的应用可以提高产品质量控制水平,确保产品符合国家标准和客户需求,通过严格把控纺织品检测标准数据,可以避免产品出现质量问题,提高消费者满意度。

提高企业市场竞争力

纺织品检测标准数据的应用可以提高企业市场竞争力,通过定期对纺织品进行检测,确保生产出的纺织品符合市场需求,提高企业的产品附加值和市场占有率。

总结与展望

纺织品检测标准数据是衡量纺织品质量的重要依据,对于保障消费者权益和提高企业市场竞争力具有重要意义,随着纺织品行业的不断发展,纺织品检测标准数据的应用将会更加广泛和深入。

纺织品检测标准数据是保障纺织品质量的重要手段,对于提高消费者满意度和提高企业市场竞争力具有重要意义,在未来的纺织品行业中,我们应该加强纺织品检测标准数据的监测和管理,确保产品质量符合国家标准和客户需求,我们也应该积极探索纺织品检测标准数据的应用新模式和新方法,提高纺织品检测的效率和准确性,为纺织品的生产和销售提供更加可靠的数据支持。

Articles related to the knowledge points of this article:

The Essential Guide to Choosing the Right Textile Processing Services

Understanding the Price Ranges of Baodu Baile Textiles