The Role of Textile Testing Laboratories and Their Accreditation Process

The role of textile testing laboratories is crucial for ensuring product quality and safety. These laboratories play a significant role in conducting rigorous tests on raw materials, intermediate products, and finished goods to determine their suitability for use by end consumers. The accreditation process ensures that these laboratories meet specific standards and adhere to the highest ethical and professional practices.,To achieve accreditation, textile testing laboratories must undergo rigorous training, adhere to strict protocols, and maintain high levels of accuracy and consistency. This includes regular audits, inspections, and evaluations to ensure that all processes are up-to-date and effective.,The importance of these laboratories cannot be overstated as they provide critical evidence for regulatory agencies, manufacturers, and consumers alike. By providing accurate and reliable results, these laboratories play a vital role in safeguarding public health and safety while promoting transparency and accountability in the industry.

In the realm of textile industry, quality control is a cornerstone to ensuring product excellence and customer satisfaction. One of the critical elements in this process is the role of textile testing laboratories, which provide essential services for testing, evaluating, and verifying textile products against standards and regulations. This paper aims to explore the importance of textile testing laboratories and the steps involved in their accreditation process.

Textile testing laboratories play an essential role in the textile industry by providing accurate and reliable results that help manufacturers ensure their products meet regulatory standards and consumer demands. These laboratories conduct a wide range of tests, including strength testing, shrinkage testing, colorfastness testing, and flame resistance testing, among others. By using advanced equipment and techniques, these laboratories can identify defects, optimize designs, and develop new materials and processes, thereby contributing to innovation and growth in the textile industry.

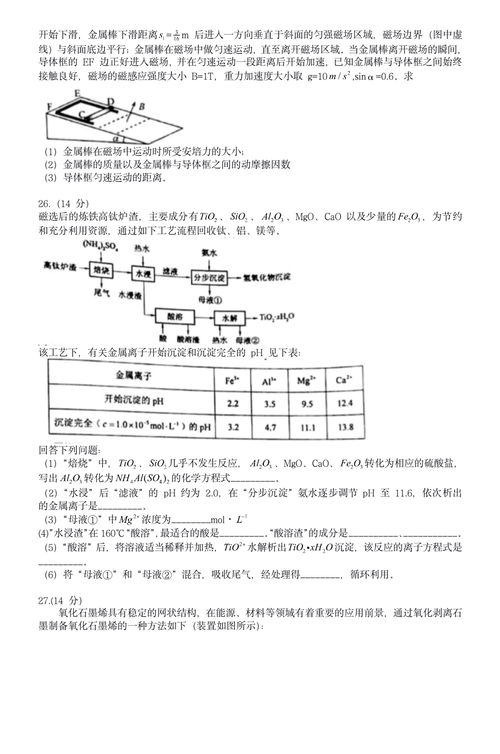

The accreditation process for textile testing laboratories is crucial in ensuring that these institutions are up to standard and can deliver consistent and reliable results. The process typically involves several steps, including:

-

Establishment of Accreditation Standards: The International Organization for Standardization (ISO) sets the global standards for accreditation of laboratory testing services, known as ISO/IEC 17025:2017. Other organizations, such as the American Society for Testing and Materials (ASTM), also have their own set of standards and guidelines for accreditation.

-

Application for Accreditation: Companies or institutions wishing to obtain accreditation must submit an application to the relevant accreditation body. This includes providing details about their organizational structure, laboratory capabilities, staff qualifications, equipment, and methods used for testing.

-

Accreditation Review: The accreditation body will review the application and conduct an on-site inspection to assess the organization's compliance with the standards and requirements. This may involve auditing records, inspecting facilities, and meeting with staff and management to discuss the application.

-

Accreditation Award: After passing the review, the accreditation body will issue an accreditation certificate to the textile testing laboratory. This certificate certifies that the laboratory has met all the required standards and is capable of providing accurate and reliable test results.

-

Continuous Auditing and Updates: Once an accreditation has been obtained, the laboratory must continue to comply with the standards and undergo regular audits. Any changes or updates to the standards may require re-accreditation.

One example of a successful textile testing lab is the National Institute of Occupational Safety and Health (NIOSH). NIOSH is an agency within the United States Department of Labor responsible for protecting workers from hazardous substances and environments. The lab is renowned for its high-quality testing services, including air quality assessments and exposure assessments for workplaces. To maintain its accreditation, NIOSH regularly undergoes audits, updates its testing methods, and works closely with industry experts to improve its testing capabilities.

In conclusion, textile testing laboratories play a vital role in ensuring the quality and safety of textile products. The accreditation process ensures that these institutions are equipped with the necessary resources, expertise, and equipment to deliver consistent and reliable test results. As more companies and industries become aware of the benefits of accredited testing laboratories, it is expected that there will be a continued demand for these services globally.

随着纺织品行业的快速发展,对纺织品的质量和安全要求也越来越高,为了确保纺织品的质量和安全,许多国家和地区都设立了纺织品检测机构,本文将围绕纺织品检测机构核准这一主题,详细介绍其流程和案例。

纺织品检测机构核准流程

申请材料准备

在申请纺织品检测机构核准之前,需要准备相关申请材料,这些材料通常包括纺织品样品、生产厂家资质证明、检测人员资质证明等。

审核材料

审核部门会对申请材料进行审核,确保材料的真实性和有效性,如果材料齐全且符合要求,将会进入下一步流程。

现场检测

在审核通过后,需要进行现场检测,检测机构会对纺织品进行全面的质量检测,包括纤维成分、化学成分、物理性能等方面的检测。

审核结果公示

检测机构会将审核结果公示,接受公众的监督,如果纺织品检测合格,将会获得纺织品检测机构的核准。

案例分析

以某地区纺织品检测机构为例,详细说明其核准流程和案例。

案例背景

该地区设立了一家纺织品检测机构,主要负责对当地纺织品的检测和质量把控,该机构经过严格的审核和现场检测,成功获得了纺织品检测机构的核准。

申请材料准备

在该案例中,申请材料主要包括纺织品样品、生产厂家资质证明、检测人员资质证明等,申请者需要提供详细的样品信息,包括样品名称、规格、数量等,还需要提供生产厂家的相关资质证明和检测人员的资质证明。

现场检测

在该案例中,检测机构对纺织品进行了全面的质量检测,对样品进行纤维成分、化学成分等方面的检测,确保样品符合国家标准,对样品进行物理性能测试,如拉伸强度、耐磨性等,确保样品在各种使用条件下都能达到预期的性能指标,根据检测结果,出具检测报告。

核准结果公示

在该案例中,经过严格的审核和现场检测,该纺织品检测机构的核准结果得到了公众的认可,该机构成功地为当地纺织品的生产和销售提供了有力的质量保障,该机构的成功经验也为其他地区设立纺织品检测机构提供了参考和借鉴。

纺织品检测机构核准是确保纺织品质量和安全的重要环节,在设立纺织品检测机构时,需要严格按照相关流程和标准进行申请和审核,还需要加强现场检测和质量控制,确保检测结果的准确性和可靠性,通过以上案例分析可以看出,纺织品检测机构核准需要严格遵守相关流程和标准,同时还需要加强质量控制和监管,确保纺织品质量和安全。

Articles related to the knowledge points of this article:

Trends in Technological Textiles and Clothing:A Comprehensive Guide

The Elegant Threads of杏林康信家用纺织品

Transforming Textiles with Creative Poster Materials

The Story of Double Connect Textiles:A Multinational Textile Company

The Inspiration Canvas:A Comprehensive Guide to Textile Design