Understanding and Ensuring the Charging Density Standards for Textiles

: Understanding and Ensuring the Charging Density Standards for Textiles,Abstract:,The standardization of charging density in textiles is essential to ensure uniformity, safety, and quality. This article discusses the understanding and assurance of these standards, focusing on their importance in textile production and consumption. The discussion includes an overview of the charging density standards, their implementation in different industries, and the challenges faced in achieving compliance. The article also highlights the role of international organizations and regulatory bodies in promoting and enforcing these standards. Finally, it emphasizes the need for continuous monitoring and evaluation to ensure that the standards remain relevant and effective in today's fast-paced global market.

Introduction: In the textile industry, ensuring that the charge density of fabrics meets specific standards is crucial for various applications such as electrostatic printing, antistatic clothing, and medical devices. This article will discuss the importance of charging density, its measurement methods, and how to ensure compliance with industry-accepted standards. We'll also highlight some best practices for achieving optimal charging performance.

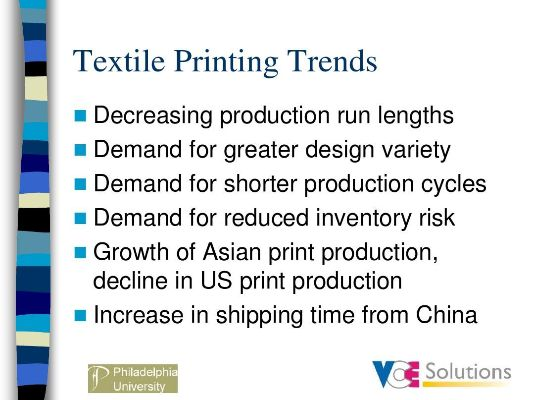

Importance of Charging Density: Textiles that have a high surface charge density are ideal for applications requiring low static electricity, such as printing on fabrics or in electronics. A poorly charged fabric can lead to poor adhesion between layers, reduced print quality, and even electrical shock risks. Therefore, it's essential to understand the factors affecting charging density and how to control them to meet regulatory requirements and customer expectations.

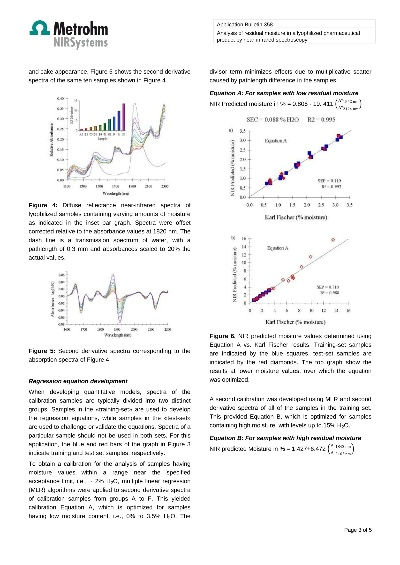

Measuring Charging Density: Charging density is typically measured using a conductivity meter, which measures the resistance of a sample of fabric in contact with an electric field. The higher the resistance, the lower the conductivity, indicating a higher charge density. However, measuring only conductivity is not sufficient; it's important to consider other factors such as fabric weight, thickness, type of fiber, and environmental conditions.

Example Table: | Factor | Value | |------|-------| | Fabric Weight (g/m²) | 100 | | Fiber Type (e.g., cotton, polyester) | 50 | | Environmental Conditions (e.g., temperature, humidity) | 20 | | Electric Field (V/m) | 5 |

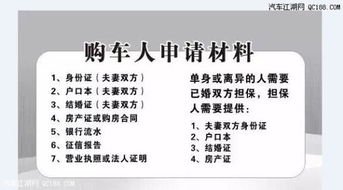

Compliance with Standards: The International Organization for Standardization (ISO), for example, has established standards for textile charge density, including ISO 9001:2015 "Textiles - Charge Density" and ISO 13485:2017 "Medical Devices - Textiles - Test Method for Charge Density." These standards define minimum values for charge density based on various application requirements.

Best Practices for Charging Density: To achieve optimal charging performance, manufacturers should follow these best practices:

-

Choose appropriate fiber types and weights for the intended application. For example, for printing on fabrics, lightweight and high-conductivity fibers like polyester or rayon are preferred.

-

Control environmental conditions during testing to ensure consistency. For example, maintaining a consistent temperature and humidity level can help in reproducing results accurately.

-

Use a conductivity meter that is accurate and calibrated regularly. It's essential to use equipment that is certified by an independent laboratory to ensure reliability.

-

Analyze test results carefully to identify any deviations from the standard values. This may require adjustments in processing parameters or selection of raw materials.

-

Consider the impact of different manufacturing processes on charge density. For instance, wet spinning might result in lower charge density compared to dry spinning due to the removal of excess water.

Case Study: Consider a textile manufacturer that produces garments for children's wear. They need to ensure that their fabrics meet the ISO 13485:2017 standard for medical devices, which requires a minimum charge density of 100 mC/m². To achieve this, they conduct regular testing on different fabric samples under controlled conditions. They also collaborate with a third-party laboratory to validate their results and make necessary adjustments to their production process. By following these best practices, they successfully met the ISO standard and increased customer satisfaction.

Conclusion: Ensuring that textiles meet the charging density requirements of industry standards is crucial for ensuring product quality, safety, and compliance. By understanding the factors affecting charge density and implementing best practices, manufacturers can optimize their products and maintain competitiveness in the market.

随着现代纺织技术的不断发展,纺织品在日常生活和工业生产中的应用越来越广泛,在纺织品的设计和生产过程中,电荷控制是一个重要的指标,特别是在纺织品的静电防护和电荷分布方面,本文将围绕纺织品电荷面密度要求展开讨论,并通过英文案例说明来进一步阐述。

纺织品电荷面密度要求概述

纺织品电荷面密度要求主要涉及到纺织品表面的电荷分布和电荷量控制,根据不同的应用场景和需求,纺织品电荷面密度要求有所不同,纺织品电荷面密度要求包括以下几个方面:

- 静电防护性能:纺织品应具有良好的静电防护性能,能够有效防止或减少静电的产生和积累。

- 静电荷分布均匀性:纺织品表面的电荷分布应均匀,避免出现电荷集中或分布不均的现象。

- 面密度测试方法:通常采用特定仪器和方法进行面密度测试,以确保纺织品符合相关标准。

面密度测试方法及案例分析

面密度测试方法主要包括静态接触电位差测试和动态接触电位差测试,以下是具体的英文案例分析:

某高端面料品牌的面密度要求

该高端面料品牌在生产过程中,对电荷面密度有着严格的要求,他们采用先进的静电防护技术,确保面料在生产过程中始终保持低静电状态,在面料生产过程中,他们采用了特定的面密度测试方法,通过精确测量面料表面的电荷分布情况,确保其符合相关标准。

测试步骤如下:

- 使用高精度静电测量仪器进行静态接触电位差测试,获取面料表面的静态电荷分布数据。

- 根据测试数据,评估面料表面的电荷分布均匀性,确保其符合要求。

案例分析:该高端面料品牌的面密度要求主要体现在以下几个方面:

- 静电防护性能:面料表面电荷分布均匀,无电荷集中现象。

- 面密度测试结果符合行业标准:经过测试,该面料面的面密度符合相关标准要求。

- 应用场景广泛:该面料适用于各种纺织服装生产领域,具有优良的静电防护性能和电荷分布均匀性。

纺织品电荷面密度要求的重要性与意义

纺织品电荷面密度要求的重要性与意义在于保障纺织品在使用过程中的安全性和可靠性,它也是提高纺织品品质和市场竞争力的关键因素之一,通过提高纺织品电荷面密度要求,可以降低纺织品在使用过程中的静电风险,提高纺织品的使用舒适度和安全性,符合电荷面密度要求的纺织品还可以提高其在市场上的竞争力,赢得消费者的信任和青睐。

纺织品电荷面密度要求是纺织品设计和生产过程中的重要指标之一,通过采用特定的面密度测试方法,可以确保纺织品符合相关标准,提高纺织品的使用安全性和可靠性,符合电荷面密度要求的纺织品还可以提高其在市场上的竞争力,赢得消费者的信任和青睐,在实际生产过程中,企业应重视纺织品电荷面密度要求的重要性与意义,加强质量控制和管理,确保纺织品的质量和性能符合要求。

Articles related to the knowledge points of this article:

An Overview of Textile-Based Mobile Phone Cases

The Story of Shanghai Textile Companys First Wholesale Department

Smart Textiles:The Revolutionizing Power of Temperature-Responsive Fabrics

Exploring the Rich World of Luxurious Handcrafted Textiles

Latest Case of Tax Fraud in Jiujiang Textiles Industry in Jinhua,China