Textile Inspection:The Art of Quality Control

: The Art of Quality Control in Textile Inspection,In the realm of textile production, quality control is not merely a checklist of parameters to be met; it is an art that demands precision and attention to detail. At the heart of this craft lies the tireless dedication of textile inspectors who meticulously scrutinize each thread of fabric, ensuring it meets the highest standards of excellence.,The inspection process begins with a thorough examination of raw materials, from the cotton to the dyes used in the manufacturing process. Each component must meet stringent specifications, from uniformity in color to consistency in texture, to ensure the end product is of unparalleled quality.,Once the raw materials are selected, the next step is the creation of patterns and designs. These are meticulously cut out using specialized machinery, ensuring every stitch is precise and consistent. The resulting fabric is then subjected to rigorous testing, including strength, durability, and colorfastness, to ensure it meets the highest industry standards.,In conclusion, textile inspection is a complex and demanding process that requires both technical expertise and a deep understanding of the materials involved. It is a testament to the craftsmanship and attention to detail that sets high-quality textile products apart from their competitors.

In the world of textiles, quality is king. From the softness of a cotton shirt to the durability of a polyester jacket, every piece tells a story about the craftsmanship and attention to detail that went into its creation. And yet, behind this beautiful fabric lies a complex system of inspections and tests designed to ensure that each item meets the highest standards of excellence. In this episode of "Quality Control in Action," we delve into the world of textile inspection and explore the importance of these rigorous processes in maintaining the trust of consumers and ensuring long-term success for manufacturers.

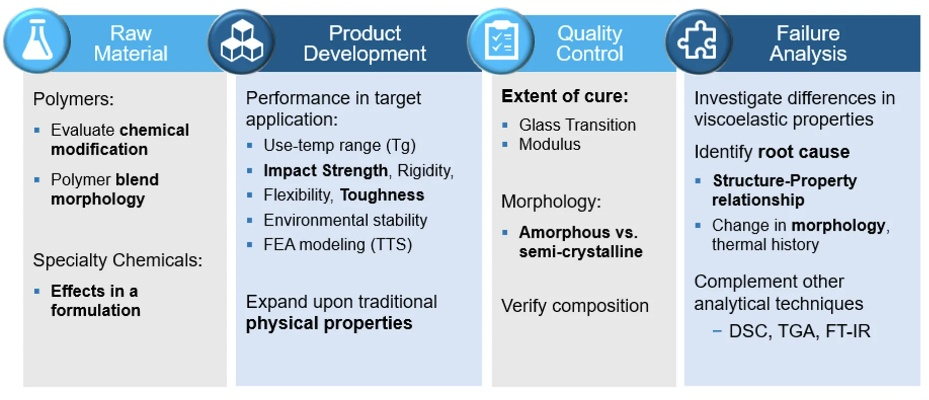

At the heart of textile inspection is the concept of "quality control." This involves a multifaceted approach that includes both pre-production testing and post-production inspections. Pre-production testing ensures that raw materials meet the necessary standards before they are used in the production process. This may involve testing for specific properties such as colorfastness or shrinkage, as well as conducting laboratory tests to evaluate the strength and durability of the fibers.

Once the materials have been processed, the next step is to inspect the finished product for defects such as thread breaks, loose threads, or uneven dyeing. This visual inspection is often accompanied by specialized tools and techniques such as calipers, magnifying glasses, and microscopes. For example, a sample of a knitted sweater might be examined under a microscope to check for any irregularities in the stitching or yarn placement.

Post-production inspections are equally important in ensuring that the final product meets customer expectations. These inspections may include further testing of the garment's fit, comfort, and performance characteristics, such as its ability to withstand wear and tear. In some cases, customers may also be invited to participate in a trial run of the product, allowing them to experience its functionality and quality firsthand.

But textile inspection is not just about catching defects; it is also about identifying potential areas for improvement. By analyzing the results of inspections, manufacturers can identify trends and patterns that will inform future production decisions. For example, if a particular type of thread consistently fails during inspections, it may be necessary to investigate the cause of the problem and make adjustments to the manufacturing process.

One particularly important aspect of textile inspection is the use of advanced technology. As the industry continues to evolve, new tools and methods are being developed to improve accuracy and efficiency. For instance, machine vision systems can be used to automate the process of detecting defects in high-value fabrics, while thermal imaging cameras can be used to quickly assess the overall quality of a garment without having to physically touch it.

Another example of the power of technology is the use of computerized inspection systems. These systems can analyze large volumes of data from multiple sources, including images and measurements taken during the manufacturing process. By comparing these data points against established quality standards, manufacturers can quickly identify any deviations and take corrective action before the product leaves the factory.

Of course, despite all the technological advancements, there is no substitute for human intuition and expertise when it comes to textile inspection. After all, what good is a perfectly accurate machine if it doesn't have the right people in place to interpret its output? That's why many textile companies invest heavily in training their employees on how to read and interpret inspection reports, as well as how to communicate these findings effectively to their teams and stakeholders.

In conclusion, textile inspection is an intricate and nuanced process that requires a combination of scientific knowledge, technical expertise, and human judgment. By investing in the latest technologies and training our staff to stay up-to-date with the latest developments, we can ensure that our products meet the highest standards of excellence and deliver exceptional value to our customers. So let us embrace the art of quality control and continue to push the boundaries of what is possible in the world of textiles.

在探讨纺织品检什么意思之前,让我们先了解一下相关背景知识,纺织品检验是指对纺织品的质量、性能和安全性进行检测和评估的过程,它涉及到纺织材料的成分、结构、外观、尺寸、耐久性等多个方面,下面我们将通过英文案例和表格来详细说明纺织品检验的意义。

纺织品检验的案例说明

纺织品质量检测

假设某公司采购了一批新布料,需要进行质量检验,通过纺织品检验,可以确保所采购的布料符合相关标准和要求,保证产品的质量和安全性,检验结果也可以作为产品质量控制的依据,为后续的生产和销售提供参考。

纺织品环保性能检测

在环保日益受到重视的今天,纺织品检验中还涉及到环保性能的检测,通过检测纺织品对环境的影响程度和可持续性,可以确保纺织品符合环保标准,为消费者提供健康、环保的产品。

纺织品检验的英文表格说明

纺织品检验流程图

| 步骤 | 描述 | 示例数据 |

|---|---|---|

| 样品准备 | 收集样品 | 从供应商处获取样品 |

| 材料分析 | 检查纤维成分 | 分析纤维成分,如纤维类型、含量等 |

| 外观检查 | 检查外观质量 | 检查面料颜色、纹理、尺寸等 |

| 尺寸测量 | 测量尺寸参数 | 测量面料尺寸,如宽度、长度等 |

| 耐久性测试 | 进行物理和化学测试 | 进行拉伸、耐磨、耐化学腐蚀等测试 |

| 结果报告 | 生成检验报告 | 将检测数据、结论等信息整理成报告 |

纺织品检验的意义与作用

纺织品检验的意义与作用主要体现在以下几个方面:

- 提高产品质量和安全性:通过纺织品检验,可以确保所采购的纺织品符合相关标准和要求,保证产品的质量和安全性,这有助于提高消费者的信任度和满意度。

- 促进产业发展:纺织品检验是纺织行业质量控制的重要环节,也是推动产业发展的重要手段,通过纺织品检验,可以促进纺织行业的健康发展。

- 保障消费者权益:纺织品检验可以保障消费者的权益,为消费者提供健康、环保的产品,纺织品检验还可以为消费者提供有关产品性能和质量的参考信息。

纺织品检验是确保纺织品质量、安全性和环保性能的重要手段,通过纺织品检验,可以确保产品的质量和安全性,促进产业发展,保障消费者权益,纺织品检验还可以为相关企业和消费者提供有关产品性能和质量的参考信息,在未来的纺织行业中,纺织品检验将会越来越受到重视。

Articles related to the knowledge points of this article:

Transforming the Local Economy with Seamens Textiles:A Success Story

A Comprehensive Look into the Different Kinds of Fibre-Picking Devices

Finding the Best Deals on Textiles in Puyang,Henan Province