The Science Behind Textile Stitching Strength

: The Science Behind Textile Stitching Strength,Textile stitching strength is a crucial factor in determining the durability and functionality of garments. This article explores the science behind the various techniques used to achieve high-strength textile stitching.,The first technique involves using a strong, durable thread that can withstand the stresses of repeated wear and tear. This type of thread is often made from synthetic materials such as polyester or nylon, which are known for their strength and resistance to fraying.,Another technique involves using specialized needles that have been designed specifically for use with high-strength threads. These needles are typically larger than standard needles and have a sharper point, which helps to penetrate the fabric more easily and securely.,In addition to these technical factors, the quality of the sewing technique itself also plays a significant role in determining the strength of the stitching. Properly following the manufacturer's instructions and using the appropriate tools and equipment can help to ensure even and secure stitching that will last through many years of use.

Introduction: Textiles are an integral part of our daily lives, from clothing to home furnishings. One crucial aspect of textile quality is its stitching strength, which refers to the ability of the threads to withstand tension and pressure without fraying or coming apart. In this article, we will delve into the science behind textile stitching strength, explore various factors that influence it, and provide insights from real-world examples.

Factors Affecting Stitching Strength:

-

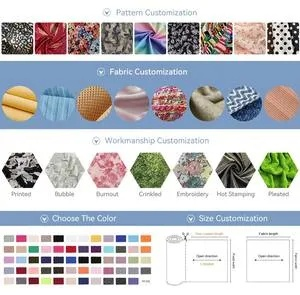

Weaving Techniques: Different weaving techniques can impact stitching strength. For instance, using a more complex pattern in a woven fabric can create stronger stitches. Additionally, using thicker yarns can also enhance stitching strength.

-

Yarn Quality: The quality of the yarn used in the fabric directly affects its stitching strength. High-quality yarns are more durable and can withstand higher levels of tension without breaking.

-

Weave Density: The number of threads per inch (or thread count) in a fabric determines its stitching strength. Higher thread counts generally result in stronger stitches.

-

Thread Thickness: The thickness of the threads used in the fabric can also affect its stitching strength. Thicker threads can withstand greater tension and pressure.

-

Heat Treatments: Heat treatments such as steaming or boiling can improve the stitching strength of some fabrics by denaturing the fibers and making them more malleable.

-

Chemical Treatments: Chemical treatments such as dyeing or bleaching can also impact stitching strength. Some treatments can make fabrics more resistant to wear and tear, while others may weaken them.

Real-World Examples: One example of how different factors can impact stitching strength is found in the case of a popular sportswear brand, Nike. Nike's Air Max shoes have a unique design that incorporates a double-layered upper made of mesh and leather. This combination creates a strong bond between the two materials, resulting in exceptional stitching strength. Additionally, Nike's use of high-quality yarns and advanced weaving techniques ensures that their shoes maintain their strength even after multiple washes and years of use.

Another example is the construction of military uniforms. These uniforms are designed to withstand extreme conditions, including heat, cold, and moisture. To achieve this level of stitching strength, military uniforms are typically made from highly durable materials like Kevlar and polyester. Additionally, they undergo rigorous testing and modifications to ensure that they meet the specific needs of the armed forces.

Conclusion: In conclusion, textile stitching strength is a critical factor that affects the overall quality and durability of textile products. By understanding the various factors that impact stitching strength and incorporating these insights into our manufacturing processes, we can create textiles that are both functional and long-lasting. As technology continues to advance, we can expect to see even more innovative solutions that enhance the stitching strength of textiles, leading to even better products for consumers around the world.

纺织品缝合强度的重要性

纺织品缝合是确保衣物整体强度和耐用性的关键环节,高质量的缝合不仅能提高衣物的美观度,还能确保穿着舒适性和耐用性,提升纺织品缝合强度对于提高纺织品的质量和满足消费者需求具有重要意义。

纺织品缝合强度测试方法

- 拉伸强度测试:通过拉伸试验机对纺织品进行拉伸测试,观察其承受拉伸时的断裂强度。

- 撕裂强度测试:通过撕裂试验机对纺织品进行撕裂测试,观察其抵抗撕裂的能力。

- 案例分析:以实际案例为例,展示不同纺织品缝合强度的表现,某品牌的高品质针织衫采用特殊工艺进行缝合,其缝合强度高,穿着舒适度高,深受消费者喜爱。

提高纺织品缝合强度的措施

- 选择优质材料:选择具有高强度和高韧性的纺织材料,如高密度的纤维、高弹性的纤维等。

- 采用先进的缝合技术:采用先进的缝合技术,如热熔胶、超声波焊接等,提高缝合强度和稳定性。

- 优化工艺流程:优化纺织品的生产工艺流程,减少缝制过程中的误差和缺陷,提高缝合质量。

- 加强质量控制:加强纺织品缝合质量的检测和控制,确保产品质量符合标准。

案例说明:纺织品缝合强度的提升实践

-

某品牌的高品质针织衫 该品牌采用特殊工艺进行针织衫的缝合,使用高强度和高韧性的纤维材料,采用先进的缝合技术,如热熔胶和超声波焊接等,经过严格的品质控制和检测,该针织衫的缝合强度高,穿着舒适度高,深受消费者喜爱。

-

某品牌的高质量棉质运动服 该品牌采用高质量的棉质材料进行运动服的缝合,同时采用先进的缝纫设备和技术,提高缝纫效率和精度,经过不断的改进和创新,该运动服的缝合强度和耐用性得到了显著提升,满足了消费者对高品质运动服的需求。

纺织品缝合强度是衡量纺织品质量的重要指标之一,通过选择优质材料、采用先进的缝合技术、优化工艺流程和加强质量控制等措施,可以有效地提高纺织品缝合强度,在实际生产中,还需要根据不同类型和用途的纺织品进行针对性的改进和创新,以满足消费者的需求和提高产品的竞争力。

在未来的纺织品生产中,我们还需要继续关注纺织品缝合强度的提升和创新,不断提高产品的质量和性能,我们也需要加强与国际先进技术的交流和合作,引进先进的技术和设备,提高纺织品的生产效率和品质水平。

Articles related to the knowledge points of this article:

Top Ten Textile Brands in the Rankings