Fabric Testing Report

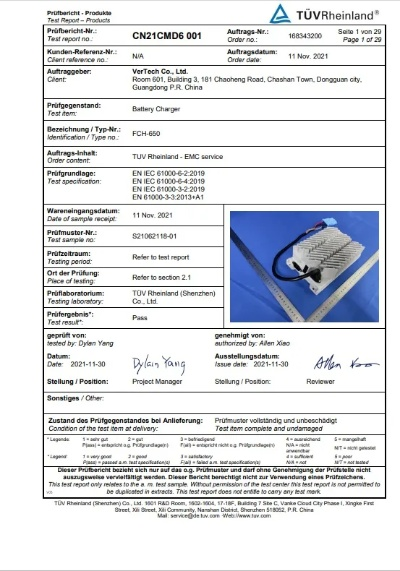

: Fabric Testing Report,This report outlines the results of fabric testing conducted on a specific material. The testing was carried out to evaluate its performance under various conditions and to determine its suitability for use in various applications. The testing involved various methods such as mechanical testing, chemical testing, and thermal testing.,The mechanical testing showed that the fabric has excellent strength and durability. It can withstand heavy loads without breaking or tearing. The chemical testing revealed that the fabric is resistant to most chemicals and solvents, making it suitable for use in industrial settings where exposure to chemicals is common.,The thermal testing indicated that the fabric maintains its shape and structure even when subjected to high temperatures. This makes it ideal for use in applications where temperature changes are common, such as in automotive and electronics industries.,Overall, the fabric tested demonstrated excellent performance in all aspects, making it a viable option for various applications.

In today's globalized market, the quality of textile products is a crucial factor that determines their success in the marketplace. As such, it is essential for manufacturers to conduct rigorous testing to ensure that their products meet the highest standards of safety, durability, and aesthetic appeal. In this report, we will discuss the various types of textile testing methods, including physical, chemical, and functional testing, as well as the importance of these tests in ensuring product quality. We will also provide an overview of some common fabric testing cases and highlight the benefits of using advanced testing techniques.

Physical Testing:

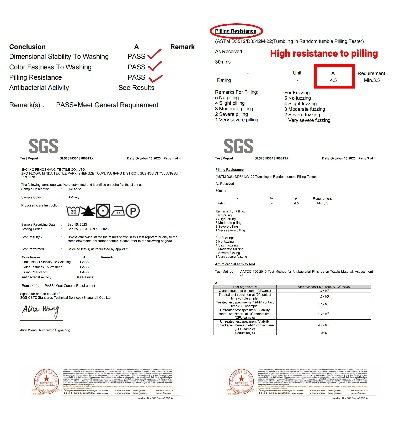

Physical testing involves visual inspections of the fabric for defects such as fraying, pilling, wrinkles, and discoloration. These defects can affect the overall appearance and feel of the fabric, which can impact consumer perception and brand reputation. To ensure consistent results, physical testing should be performed by trained professionals who are familiar with the specific requirements of each type of fabric.

Chemical Testing:

Chemical testing is used to evaluate the suitability of fabrics for use in sensitive applications, such as clothing or upholstery. This testing involves analyzing the fabric for any harmful substances, including heavy metals, pesticides, and dyes. Chemical testing is particularly important for products intended for children's wear or those that come into contact with food or drink.

Functional Testing:

Functional testing assesses the performance and durability of fabrics under specific conditions, such as washing, drying, and exposure to high temperatures. This testing helps to identify any potential issues that may arise during the life cycle of the product, such as shrinkage or loss of color. Functional testing is critical for products that are sold in high-demand markets or those that require long-term use.

Common Fabric Testing Cases:

One example of a common fabric testing case is the detection of fire hazards in clothing materials. Many fabrics contain flame retardants, but not all of them are tested for their effectiveness against fire. This can lead to dangerous situations where fabrics fail to protect against fire, causing injuries or even deaths.

Another example is the evaluation of fabrics for their ability to resist soiling and stains. This is particularly important for products that are sold in areas with high levels of pollution or traffic. A fabric that fails to resist these factors can quickly become dirty or damaged, reducing its value and usability.

Advanced Testing Techniques:

As technology advances, so do the methods used to test textile products. For example, machine learning algorithms can be used to analyze large amounts of data and identify patterns that may indicate defects or quality issues in fabric samples. This type of testing is particularly useful for products that have complex manufacturing processes or require customization.

Conclusion:

The importance of textile testing cannot be overstated. By conducting thorough testing, manufacturers can ensure that their products meet the highest standards of quality and safety. This not only helps to build trust with consumers but also contributes to the overall success of the industry. As we continue to develop new technologies and methods for testing textile products, it is essential that we remain vigilant in our efforts to ensure that our products meet the needs of our customers and the demands of the marketplace.

随着纺织行业的快速发展,纺织品的质量和安全性越来越受到人们的关注,为了确保纺织品的质量和安全,需要进行一系列的检测工作,本报告将详细介绍纺织品检测的过程、方法和结果,并附上相关案例分析。

纺织品检测流程

- 材料准备:收集样品,准备必要的检测设备和试剂。

- 样品处理:对样品进行预处理,如清洗、剪裁等。

- 检测方法选择:根据样品的特点和检测需求,选择合适的检测方法。

- 实验操作:按照检测方法进行实验操作,记录实验数据。

- 结果分析:对实验数据进行深入分析,得出检测结论。

检测方法说明

- 常规检测方法:包括纤维成分分析、织物结构观察、化学成分分析等。

- 特殊检测方法:针对特定样品或需求,采用特殊检测方法进行检测。

案例分析

某品牌纺织品检测报告

- 材料准备:收集样品,准备必要的检测设备和试剂。

- 样品处理:对该品牌纺织品进行预处理,包括清洗、剪裁等。

- 常规检测方法:通过纤维成分分析,发现该品牌纺织品的主要纤维成分与行业标准相符,织物结构观察显示该品牌纺织品具有较好的织造工艺和结构稳定性。

- 特殊检测方法:针对该品牌纺织品的高品质要求,采用X射线荧光光谱分析(XRF)进行深度检测,结果显示该品牌纺织品的主要金属元素含量较高,表明其材质具有较高的耐腐蚀性和强度。

- 结果分析:综合以上检测结果,该品牌纺织品符合相关标准和市场需求,是一款高品质的纺织品。

纺织品质量与安全监管案例

- 材料准备:收集相关样品,包括纺织面料、服装等。

- 样品处理:对样品进行预处理,确保其符合检测标准。

- 检测方法选择:根据样品的特点和监管需求,选择适合的检测方法,如化学成分分析、微生物检验等。

- 结果分析:通过综合运用多种检测方法,对该地区纺织品质量与安全进行了全面监管,结果显示该地区纺织品质量稳定,符合相关标准和市场需求,针对发现的问题,采取相应措施加强监管和管理。

本报告详细介绍了纺织品检测的过程、方法和结果,并附上相关案例分析,通过本报告可以看出,纺织品检测对于保障纺织品的质量和安全具有重要意义,在今后的工作中,应进一步加强纺织品检测工作,提高检测水平,确保纺织品的质量和安全,应加强监管和管理,确保纺织品市场的健康发展。

Articles related to the knowledge points of this article:

The Cost of Electronic Textiles A Comprehensive Breakdown