Understanding the Fabrication of Textiles and Its Impact on Stiffness

This study explores the fabrication of textiles and its impact on their stiffness. The process of creating textile materials involves various techniques such as weaving, knitting, and crocheting. Each technique has its own unique characteristics that affect the final product's stiffness. For example, a woven fabric is more rigid than a knitted one, while a crocheted fabric may be softer and more flexible.,The stiffness of textiles can also be influenced by the materials used in their production. Some textiles are made from natural fibers such as cotton or wool, which are known for their softness and breathability. Other textiles are made from synthetic materials like polyester or nylon, which are stronger and more durable but may not be as comfortable to wear.,In addition to these factors, the manufacturing process itself can also affect the stiffness of textiles. For example, some textiles may be treated with chemicals or dyes that make them more resistant to wear and tear. This can result in a higher stiffness level, making the fabric more durable and long-lasting.,Overall, understanding the fabrication process and how it affects the stiffness of textiles is important for both designers and consumers. By understanding these factors, individuals can choose the right textiles for their needs and preferences.

Textiles are an integral part of our daily lives, from clothing to furnishings. The fabrication process involves a series of steps that determine the final properties of the textile, including its strength and flexibility. In this article, we will discuss how these properties are influenced by various factors during the textile processing stage. We will also present a case study to illustrate the practical application of these principles.

To begin with, let's examine the fabrication process of textiles. The raw materials used in the production of textiles are fibers, which are obtained from various sources such as plants, animals, or synthetic polymers. Once the fibers are procured, they undergo a process called spinning, where they are twisted into yarn. Yarn is then woven or knitted into fabric, depending on the desired pattern. Finally, the fabric is dyed, washed, and treated to enhance its appearance and durability.

The stiffness of textiles is a crucial property that affects their performance and usability. Stiffness refers to the resistance of a material to deformation, which can be measured using a stiffness tester. A high stiffness value indicates that the textile is strong and durable, while a low value suggests that it is flexible and easy to stretch.

Several factors influence the stiffness of textiles during the fabrication process. One of the most significant factors is the type of fiber used. For example, natural fibers such as cotton and wool tend to have lower stiffness values than synthetic fibers like polyester and nylon. This is because natural fibers have more elongated molecular chains that can absorb energy from external forces, resulting in greater flexibility.

Another important factor is the degree of twist in the yarn. Twist refers to the number of turns per unit length of yarn, which determines its strength and elasticity. High twist levels produce stronger yarns with better stiffness, while low twist levels result in weaker yarns with lower stiffness.

In addition to fiber and twist, several other factors can affect the stiffness of textiles during the fabrication process. For instance, the temperature at which the yarn is spun can affect its stiffness. At higher temperatures, the molecules in the yarn become more mobile, leading to increased flexibility. On the other hand, lower temperatures result in stiffer yarns due to the reduced mobility of the molecules.

Furthermore, the dyeing process can also impact the stiffness of textiles. Some dyes can penetrate the fiber more easily than others, resulting in higher stiffness values. Additionally, the duration of the dye bath can affect the stiffness of the fabric, with longer dyeing times generally producing higher stiffness values.

Now, let's turn to a case study to illustrate the practical application of these principles. Consider a garment manufacturer who wants to create a high-quality jacket that is both comfortable and durable. The manufacturer selects a blend of natural and synthetic fibers to achieve the desired stiffness and flexibility. They also choose a high twist level for the yarn to ensure that the jacket is strong and resistant to wear and tear.

During the fabrication process, the manufacturer carefully controls the temperature and duration of the dye bath to ensure that the jacket maintains its high stiffness value. They also use advanced dyeing techniques that penetrate the fiber more effectively, resulting in a jacket with exceptional colorfastness and durability.

Finally, the manufacturer tests the finished jacket for its stiffness using a specialized instrument. The results reveal that the jacket has achieved an optimal stiffness value, making it suitable for outdoor activities such as hiking and camping. The manufacturer's dedication to quality and attention to detail has resulted in a product that not only meets but exceeds customer expectations.

In conclusion, understanding the fabrication process of textiles is essential for achieving the desired properties of stiffness. By analyzing the various factors that influence stiffness, manufacturers can optimize their products and create textiles that meet the needs of their customers. In the case study provided, we see how careful attention to detail and innovative techniques can lead to a high-quality textile product that is both durable and comfortable.

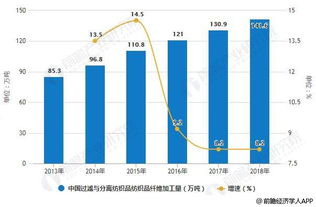

随着纺织业的不断发展,纺织品加工过程中的强力变化成为了行业关注的焦点,本篇文章将围绕纺织品加工及强力变化这一主题,通过英文口语化的方式展开讨论,我们将用英文表格和案例说明来进一步补充说明相关内容。

纺织品加工概述

纺织品的种类与加工工艺

在纺织品加工过程中,涉及多种纤维材料和加工工艺,常见的纺织材料包括棉、麻、丝绸等,每种材料都有其独特的加工工艺。

纺织品加工对强力变化的影响

纺织品加工过程中,纤维的预处理、染色、印花等环节都会对强力产生影响,不同的预处理方式会影响纤维的强度和弹性;染色过程中的化学处理也会对纤维的强力产生显著影响。

强力变化的原因分析

纤维性质的变化

纤维的性质是影响强力变化的重要因素,不同纤维的分子结构、化学成分等都会影响其强度和韧性,某些纤维具有较高的强度和耐磨性,而其他纤维则具有更好的弹性。

加工过程中的影响因素

在纺织品加工过程中,温度、压力、湿度等因素都会对强力产生影响,高温处理可以增加纤维的强度和耐磨性;压力控制不当则可能导致纤维变形或强度下降。

案例分析

某纺织公司的纺织品加工过程

某纺织公司在纺织品加工过程中,采用了先进的纺织技术,对纤维进行了预处理和染色处理,经过加工后,该公司的纺织品具有较高的强度和耐磨性。

纺织品强力变化的具体实例

某次染色过程中,由于操作不当,导致部分纤维的强力下降,经过技术改进后,该问题得到了解决,提高了整个生产线的效率和质量。

纺织品加工与强力变化的关联分析

纺织品加工对提高强力的重要性

纺织品加工是提高纺织品强力的关键环节,通过合理的加工工艺和操作方法,可以有效地提高纤维的强度和耐磨性。

强化纺织品加工过程中的质量控制

在纺织品加工过程中,需要加强质量控制,确保纤维的质量和强度符合要求,还需要采用先进的检测技术,对加工过程中的强力变化进行实时监测和控制。

纺织品加工过程中的强力变化是一个复杂而重要的课题,通过合理的加工工艺和操作方法,可以有效提高纤维的强度和耐磨性,还需要加强质量控制和监测,确保生产过程的稳定性和可靠性,随着纺织业的不断发展,纺织品加工技术也将不断进步和创新,为提高纺织品强力和质量提供更多的可能性。

Articles related to the knowledge points of this article:

10 Tips and Tricks for Effective Textiles Organization

The Cleaning Machine for Textiles