Revolutionizing Textiles with Laser Engraving Technology

Laser engraving technology has revolutionized the way textiles are produced. This innovative process involves using high-powered lasers to create intricate patterns and designs on fabrics, making them more durable and visually appealing. The laser beam is focused onto the surface of the fabric, causing it to melt and fuse together, leaving behind a permanent imprint of the design. This technique not only enhances the aesthetic appeal of textiles but also improves their functionality by creating stronger, more resistant materials. Additionally, laser engraving can be used to add personalized touches to clothing, such as names or initials, making them more unique and special. As demand for high-quality, customizable textiles continues to grow, the potential for laser engraving technology to transform the fashion industry is vast.

Laser engraving technology has revolutionized the textile industry, transforming the way we perceive and interact with clothing. With its ability to create intricate designs and patterns on fabric, this cutting-edge technology has opened up a world of possibilities for designers and manufacturers alike. In this article, we will explore the benefits of laser engraving technology, highlight some successful cases, and provide an overview of the tools and techniques involved in this process.

At its core, laser engraving is a method of creating permanent markings on materials using a focused beam of light. Unlike traditional engraving methods that rely on heat or chemicals, laser engraving uses a high-powered laser beam to irradiate the surface of the material, causing it to melt and solidify. This process creates a precise, detailed design that can be easily replicated and scaled up.

One of the key benefits of laser engraving technology is its speed and precision. Unlike traditional engraving methods, which can take hours or even days to complete, laser engraving can produce intricate designs within minutes. Additionally, laser engraving produces high-quality results that are not easily replicated by other methods.

In recent years, there have been several successful cases of laser engraving technology being used in the textile industry. One such example is the use of laser engraving in fashion accessories such as belts, bags, and jewelry. Designers have been able to create unique and eye-catching patterns on these items using laser engraving technology, making them more attractive and desirable to consumers.

Another area where laser engraving technology has found success is in the production of high-end sportswear. Many companies are now using laser engraving to create personalized logos, initials, and other identifying features on their products. This not only adds a touch of individuality to the product but also helps to differentiate it from competitors.

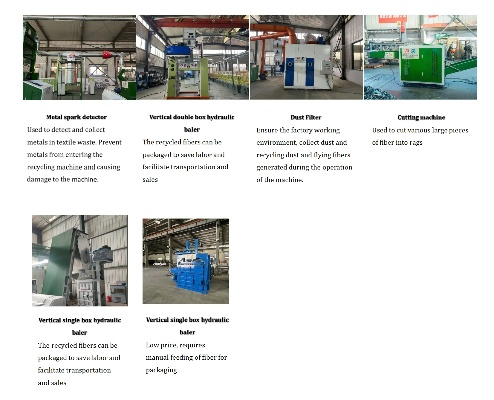

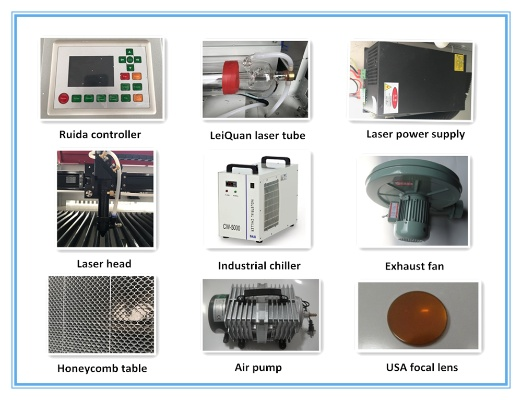

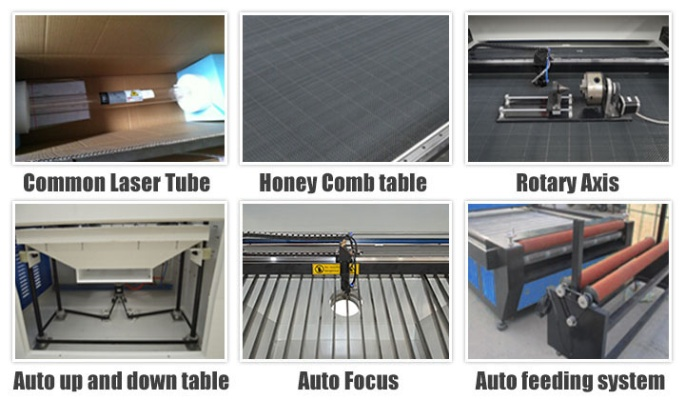

To achieve laser engraving on textiles, there are several tools and techniques that must be mastered. The first step is to choose the right laser engraving system, which should be capable of handling the type of material being worked with (e.g., polyester, cotton, etc.). Once the system is selected, the next step is to prepare the material for engraving by cleaning it and applying a protective coating.

Once the material is ready, the laser engraving process begins. The laser beam is directed onto the surface of the material, causing it to melt and solidify. The laser's power and focus determine the depth and quality of the engraving. To achieve the desired effect, it is important to experiment with different settings and parameters until the desired pattern is created.

In addition to laser engraving, there are also other techniques that can be used to create intricate designs on textiles. For example, watermarking involves printing a logo or message onto the fabric using a special inkjet printer. This technique can be used to create high-quality, long-lasting watermarks that are difficult to remove.

Another technique that has gained popularity in recent years is screen printing. Instead of using a laser beam, screen printing uses a series of small mesh screens to transfer ink onto the fabric. This technique allows for a wider range of designs and colors than laser engraving, making it ideal for producing complex patterns and graphics.

In conclusion, laser engraving technology has revolutionized the textile industry by providing designers and manufacturers with new and exciting ways to create intricate designs on fabric. From fashion accessories to high-end sportswear, laser engraving has become an essential tool in today's competitive market. As this technology continues to evolve, we can expect to see even more innovative applications in the future.

随着科技的飞速发展,纺织品加工领域也迎来了新的变革,我们将探讨一种新型的纺织品加工技术——纺织品能激光刻花,并探讨其在现代纺织品生产中的应用和优势。

激光刻花技术简介

激光刻花技术是一种利用激光束在纺织品表面进行精细雕刻的技术,它可以通过高精度控制激光束的路径和强度,实现对纺织品图案的精确复制和个性化定制,与传统的手工雕刻相比,激光刻花技术具有更高的效率和精度,同时还能实现批量生产,大大提高了生产效率。

案例分析

以某知名品牌为例,该品牌采用激光刻花技术对纺织品进行加工,展示了其在现代纺织品生产中的应用和优势。

- 材料选择:该品牌选择高质量的纤维材料进行加工,以确保产品的质量和性能。

- 工艺流程:使用专业的设备对纺织品进行预处理,包括清洗、烘干等,通过激光刻花设备进行精细雕刻,最后进行后续处理,如染色、印花等。

- 效果展示:经过激光刻花处理后的纺织品具有独特的纹理和图案,与传统的纺织品相比,更加精美、细腻,该品牌还实现了批量生产,大大提高了生产效率。

激光刻花技术在纺织品生产中的应用

- 提高生产效率:激光刻花技术可以实现快速、高效的纺织品加工,大大提高了生产效率。

- 提高产品质量:通过精确控制激光束的路径和强度,可以实现纺织品图案的精确复制和个性化定制,从而提高产品质量。

- 拓展应用领域:激光刻花技术不仅可以应用于纺织品加工,还可以应用于其他材料加工领域,如服装、家居用品等。

激光刻花技术的优势

- 高精度控制:激光刻花技术可以通过高精度控制激光束的路径和强度,实现对纺织品图案的精确复制和个性化定制。

- 快速加工:激光刻花技术可以实现快速加工,大大缩短了生产周期。

- 环保节能:激光刻花技术采用环保材料和节能设备,符合现代绿色制造的理念。

随着科技的不断发展,激光刻花技术将在纺织品生产领域发挥越来越重要的作用,它不仅可以提高生产效率、提高产品质量,还可以拓展应用领域,随着技术的不断进步和创新,激光刻花技术将会更加成熟和完善,为纺织品生产带来更多的可能性。

Articles related to the knowledge points of this article:

Trends in Technological Textiles and Clothing:A Comprehensive Guide