The Future of Textile Inspection:Opportunities and Challenges

"The Future of Textile Inspection: Opportunities and Challenges",Textile inspection is a crucial step in the manufacturing process, ensuring that products meet quality standards. With advancements in technology, there are both opportunities and challenges for the future of textile inspection. On the one hand, machine vision and artificial intelligence can improve accuracy and efficiency, reducing labor costs. On the other hand, there is a risk of automation replacing human workers, leading to job losses. Additionally, new materials and dyes require special inspection methods, making it difficult to keep up with the ever-changing market demands. However, with proper training and investment in research and development, the industry can overcome these challenges and continue to grow.

Introduction: Textiles, the fabric of our lives, play a crucial role in our daily existence. They are not just functional but also aesthetically pleasing. As technology advances, so too does the need for quality assurance in the textile industry. Textile inspection is a critical aspect that ensures the safety, durability, and quality of these products. In this article, we will explore the future of textile inspection and its potential impact on the industry.

Textile Inspection: Textile inspection involves the examination of raw materials, intermediate products, and final products to ensure they meet certain standards and regulations. This process includes testing for defects such as thread breaks, color variations, and shrinkage. Textile inspection is essential for industries like apparel, textiles, and home furnishings, where even minor flaws can compromise product performance or safety.

Future of Textile Inspection: The future of textile inspection is promising, with advancements in technology offering new ways to improve efficiency and accuracy. Here's a breakdown of some of the key trends:

-

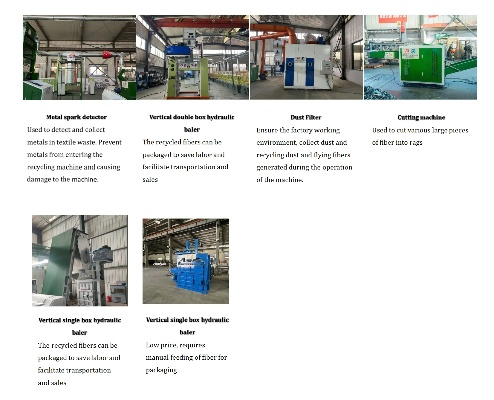

Automation and Machine Learning: As automation becomes more prevalent in various industries, it is expected to see similar advancements in textile inspection. Advanced algorithms can analyze images captured by sensors and identify defects automatically. This can significantly reduce labor costs and increase throughput.

-

3D Printing and Digital Simulation: With the advent of 3D printing, digital simulations can be used to create accurate models of finished products. These models can then be inspected for any flaws before production begins. This approach can help reduce waste and improve product quality.

-

Smart Sensors and Devices: Advanced sensors and devices can detect specific types of defects at different stages of the production process. For example, sensors placed near the end of the production line can pick up issues before they reach the final product.

-

Internet of Things (IoT): The integration of IoT devices into the textile inspection process can provide real-time data on production processes. This information can be used to optimize workflows and identify areas for improvement.

-

Artificial Intelligence (AI): AI can be used to analyze large amounts of data and identify patterns that may not be visible to human eyes. This can help predict defects before they occur and prevent them from being introduced into the final product.

Case Study: One company that has successfully implemented advanced textile inspection techniques is Pima Cotton. Pima Cotton uses machine learning algorithms to analyze images of cotton linters and identify any defects before they become a problem. This has led to significant improvements in product quality and reduced costs for both the company and its customers.

Conclusion: The future of textile inspection looks bright, with advancements in technology offering new ways to improve efficiency and accuracy. Advancements in automation, IoT, AI, and 3D printing are just some of the trends that are shaping the industry. As these technologies continue to evolve, we can expect to see even more innovative solutions that will transform the way we inspect textiles.

I: Introduction

大家好,今天我们来探讨一下纺织品检测这个领域的前途,纺织品是日常生活中不可或缺的商品,其质量直接关系到人们的健康和安全,纺织品检测在纺织行业中扮演着至关重要的角色。

II: 纺织品检测的重要性

纺织品检测的重要性体现在以下几个方面:

- 保障产品质量:纺织品的质量直接关系到人们的穿着和使用的舒适度,通过纺织品检测,可以确保产品的质量符合国家标准,保障消费者的权益。

- 推动行业发展:纺织品检测是纺织行业发展的重要支撑,随着人们对纺织品质量要求的不断提高,纺织品检测技术也在不断进步,为纺织行业的发展提供了强有力的支持。

III: 纺织品检测的现状与前景

纺织品检测行业呈现出以下几个特点:

- 技术发展迅速:随着科技的不断进步,纺织品检测技术也在不断更新换代,现代纺织品检测技术更加精准、高效,能够满足更严格的质量要求。

- 应用领域广泛:纺织品检测的应用领域非常广泛,包括纤维含量检测、化学成分分析、微生物污染检测等,在国内外市场上,纺织品检测已经成为了一个重要的环节。

对于纺织品检测的前途,我们可以从以下几个方面进行探讨:

国外纺织品检测的发展趋势

近年来,国外纺织品检测行业取得了显著的发展,某大型跨国公司采用了先进的纺织品检测技术,对原材料进行严格的质量控制,确保产品的质量符合国际标准,该公司在全球范围内建立了多个检测中心,为消费者提供了更加便捷、可靠的纺织品检测服务。

国内纺织品检测的现状与前景

纺织品检测行业也呈现出良好的发展态势,随着人们对纺织品质量要求的不断提高,纺织品检测行业得到了越来越多的关注和支持,政府也出台了一系列政策措施,鼓励和支持纺织品检测行业的发展,随着技术的不断进步和市场的不断扩大,纺织品检测行业将会迎来更加广阔的发展空间。

IV: 纺织品检测的未来展望

对于纺织品检测的未来展望,我们可以从以下几个方面进行探讨:

- 技术创新:纺织品检测行业将会继续加强技术创新,不断提高检测技术的精度和效率,还将引入更多的先进技术手段,如人工智能、大数据分析等,为纺织品检测提供更加智能、高效的服务。

- 应用领域拓展:纺织品检测行业将会拓展更多的应用领域,包括绿色纺织品的检测、功能性纺织品的检测等,还将加强与国际市场的合作与交流,为纺织品的出口提供更加便捷、可靠的检验服务。

- 政策支持:政府将会继续加强对纺织品检测行业的支持力度,出台更多的政策措施,鼓励和支持纺织品检测行业的发展,还将加强对纺织品的监管力度,保障消费者的权益和安全。

纺织品检测行业是一个充满机遇和挑战的领域,随着技术的不断进步和市场的不断扩大,纺织品检测行业将会迎来更加广阔的发展空间,我们也需要加强技术创新和人才培养,提高纺织品检测的质量和水平。

Articles related to the knowledge points of this article:

Top Ten Best Home Appliances in Jiangsu,China