The Art of Creating Fashionable Textile Shipyards

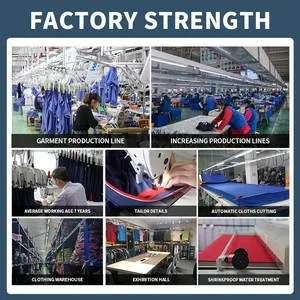

"The Art of Creating Fashionable Textile Shipyards" is an exploration into the creative process behind creating trendy and stylish textile factories. The focus is on the innovative design, meticulous craftsmanship, and attention to detail that goes into transforming raw materials into high-quality textile products. The paper emphasizes the importance of incorporating modern technology and sustainable practices to ensure the longevity and sustainability of these facilities. Additionally, it discusses the significance of aesthetics in designing textile shipyards, highlighting how their visual appeal can enhance the overall industrial experience for both workers and customers. Overall, the study aims to inspire designers and manufacturers to push the boundaries of fashion and functionality, resulting in a unique and memorable textile industry.

Introduction: In the world of fashion and textiles, the concept of shipyards has taken on a new meaning in recent years. Instead of traditional wooden ships, we now refer to these as "textile ships" that are designed and crafted with the same attention to detail and craftsmanship as their wooden counterparts. In this article, we will delve into the process of creating these textile ships, from the initial design to the final product.

Designing the Textile Ship: The first step in creating a textile ship is to have a clear vision for what it is intended to be. This includes deciding on the type of material to use, the style of the ship, and any specific features or details that should be incorporated into the design. Once this has been established, the designer must then sketch out a detailed blueprint of the ship's structure, including its dimensions, shapes, and proportions.

Choosing the Right Material: The choice of material plays a crucial role in the overall look and feel of the textile ship. Common materials used for shipbuilding include cotton, linen, wool, and synthetic fabrics such as polyester and nylon. Each material has its own unique properties, such as durability, softness, and weight, which need to be considered when selecting the right one for the project.

Sketching and Blueprintting: Once the design has been finalized, the next step is to create a detailed blueprint of the ship's structure. This involves carefully drawing out every inch of the ship's outline, including its lines, curves, and angles. It is important to ensure that the blueprint is accurate and precise so that the actual textile ship can be built to perfection.

Cutting and Weaving: The next step is to cut and weave the fabric into the desired shape and size of the textile ship. This requires a skilled team of seamstresses who can work with precision and care to create a seamless and durable fabric. They may also use specialized tools such as crochet hooks, needles, and scissors to achieve the desired effect.

Construction: Once the fabric has been cut and woven, it is time to construct the actual textile ship. This involves attaching the pieces together using strong stitches and ensuring that they fit together perfectly. The construction process may involve several layers of fabric, each one contributing to the overall strength and stability of the ship.

Detailing: Once the basic structure of the textile ship has been completed, it is time to add any additional features or decorations that were included in the original design. This may include adding handles, decorative trimmings, or even small pockets or compartments for storage.

Testing and Quality Control: Finally, it is essential to test the textile ship thoroughly to ensure that it meets all safety standards and performs well in practical use. This may involve inspecting for any defects or flaws in the fabric, checking the integrity of the seams, or conducting tests to determine how well the ship floats and navigates in water.

Case Study: One example of a successful textile ship creation is the "Vogue Ship," which was designed by renowned fashion designer Karl Lagerfeld. The Vogue Ship was made entirely of luxurious silk fabric and featured intricate designs inspired by classic sailing ships. It was created as a collaboration between Karl Lagerfeld and British luxury yacht builder Bentley Motors, and was launched at the end of last year. The Vogue Ship was not only a stunning piece of art but also a testament to the incredible craftsmanship and attention to detail that goes into creating truly exceptional textile ships.

Conclusion: Creating textile ships is a complex and challenging process that requires a keen eye for design, a skilled hands-on approach, and an unwavering commitment to quality. From the initial design to the final product, every step of the process must be executed with precision and care to ensure that the textile ship stands out as a true masterpiece. With the right materials, skilled craftsmen, and dedication, anyone can create a textile ship that is both beautiful and functional, capturing the essence of the sea and the thrill of exploration.

纺织品船样制作概述

随着现代工业的飞速发展,纺织品船样制作已成为船舶制造领域中的重要环节,它不仅涉及到纺织材料的挑选、工艺流程的设计,还涉及到精细的模具制作和后期处理,本文将详细介绍纺织品船样制作的流程和注意事项,并结合实际案例进行说明。

纺织品船样制作流程

材料准备

在纺织品船样制作过程中,首先需要准备好所需的纺织材料,这包括各种纤维、纱线、面料等,在选择材料时,需要考虑材料的强度、柔软度、吸湿性等因素,以确保制作出的船样具有良好的性能。

设计图纸

根据船舶的设计要求,绘制出详细的船样设计图纸,图纸中应包括船体结构、舱室布局、装饰元素等,设计图纸应简洁明了,便于后续制作和修改。

模具制作

模具是纺织品船样制作的关键环节,根据设计图纸,使用专业的模具制作工具,制作出精确的模具,模具的制作需要考虑到材料的特性、工艺要求等因素,以确保模具的精度和稳定性。

纺织工艺流程

在模具制作完成后,需要进行纺织工艺流程,首先进行预处理,包括清洗、烘干等;然后进行织造,根据设计图纸的要求,将纤维织成船体结构;最后进行后处理,包括整理、定型等,以确保船样的外观和质量。

后期处理

完成纺织工艺流程后,需要进行后期处理,这包括对船样进行防水处理、防潮处理、防霉处理等,以确保船样的使用寿命和性能,还需要对船样进行打磨、修整等,以达到最终的制作效果。

实际案例说明

以某知名船舶制造公司为例,其纺织品船样制作过程如下:

-

材料准备:该公司选择高质量的纤维材料,如涤纶纤维、棉纤维等,以确保船样的性能和质量。

-

设计图纸:该公司根据船舶的设计要求,绘制出详细的船样设计图纸,图纸中包含了船体结构、舱室布局、装饰元素等,确保了船舶的美观和实用性。

-

模具制作:该公司使用专业的模具制作工具,制作出精确的模具,在模具制作过程中,该公司注重材料的特性和工艺要求,以确保模具的精度和稳定性。

-

纺织工艺流程:该公司按照纺织工艺流程进行纺织制作,首先进行预处理,清洗烘干;然后进行织造,使用先进的织造技术将纤维织成船体结构;最后进行防水处理和修整等后期处理,经过精细的制作和修改,最终制作出一艘高质量的纺织品船样。

纺织品船样制作是一项精细而重要的工作,它涉及到材料选择、设计图纸、模具制作、纺织工艺流程和后期处理等多个环节,在制作过程中,需要注意材料特性和工艺要求,确保制作出的船样具有良好的性能和质量,在实际操作中,还需要注重细节和精度,以确保最终制作的成品符合要求。

Articles related to the knowledge points of this article:

The Art of Interior Textiles:Crafting a Masterpiece in the Canvas

The Expanding Horizons of Textiles in Modern Society

Blue Dream Textiles:A Journey Through Quality and Innovation

Exploring the Infrastructure of Shangrao Textiles Logistics

The Transformative Power of Specialized Textile Treatment Devices