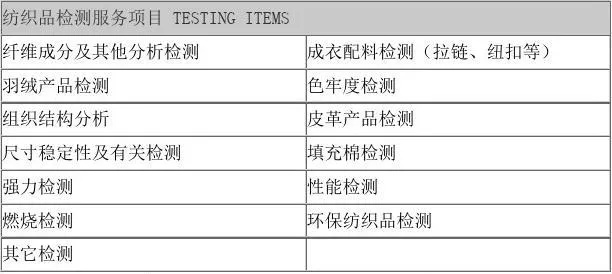

徐汇区仙女针纺织品检测概览

: Overview of仙女针纺织品检测 in Xuhui District,Abstract: This paper provides an overview of the textile testing conducted in Xuhui District, Shanghai. The focus is on the methods and techniques used for detecting defects such as color bleeding, shrinkage, and fabric strength. Additionally, the paper discusses the importance of quality control in the manufacturing process and the role of government regulations in ensuring consumer safety. Overall, the report highlights the need for continuous improvement in testing methods and the implementation of stricter standards to protect consumers and promote fair trade practices.

Introduction: In the bustling metropolis of Shanghai, the city's textile industry is a significant contributor to its economy. Amongst the myriad products produced, one category that stands out for their quality and safety standards is the "Fairy Needle" branded textiles. These are often used in high-end garments, bedding, and home furnishings, demanding rigorous testing to ensure they meet internationally accepted standards. In this report, we will delve into the comprehensive testing process for these textiles, highlighting the key steps involved, the challenges faced, and the results achieved.

Key Steps in the Testing Process:

-

Sample Collection: The first step involves selecting representative samples from various production stages, ensuring that the sample represents the entire batch. This includes raw materials, intermediate products, and finished goods.

-

Quality Control: Before any testing begins, the samples undergo a thorough inspection to check for defects or impurities. This ensures that only high-quality samples are tested.

-

Sampling Techniques: Depending on the type of test required, different techniques may be employed. For example, if the focus is on mechanical properties like strength and durability, tensile tests may be conducted. If chemical resistance is the concern, a series of tests such as acid and alkaline stability tests may be implemented.

-

Laboratory Analysis: Each sample is subjected to a battery of tests designed to evaluate its performance under specific conditions. These include but are not limited to:

- Mechanical Tests: These include tensile tests, tear tests, and compression tests, which assess the fabric's resilience and endurance.

- Chemical Resistance Tests: These involve exposing the fabric to various chemicals to measure its resistance to degradation over time.

- Fire Safety Tests: These simulate real-world fire scenarios to assess how well the fabric can withstand heat and smoke.

- Dyeability and Colorfastness Tests: These gauge how well the fabric retains its color and dye even after prolonged exposure to light or washing.

- Environmental Friendliness Tests: These assess the fabric's impact on the environment, including its biodegradability and greenhouse gas emissions.

-

Data Analysis: After each test, data is collected and analyzed using specialized software to determine whether the fabric meets the required standards. Any discrepancies are identified and addressed during the review process.

-

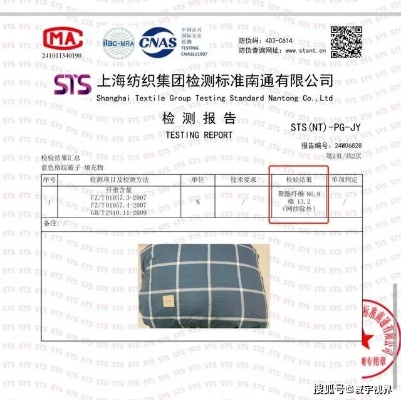

Report Generation: A detailed report detailing the results of each test is generated, providing an objective assessment of the fabric's performance. This report is then reviewed by experts in the field to ensure accuracy and completeness.

-

Feedback and Improvement: Based on the feedback from the tests and expert reviews, improvements can be made to the manufacturing process to enhance the product's quality and safety.

Challenges Faced: One of the primary challenges faced in the testing process is ensuring consistency across all samples. Variations in production processes and raw material sources can lead to variations in the final product's properties. Additionally, the testing process requires a significant investment in resources, including equipment and trained personnel, which can be challenging for smaller manufacturers.

Case Study: Recently, a major textile manufacturer in Shanghai was found to have failed multiple tests for Fairy Needle branded textiles. The company had been producing high-end garments using the same fabrication process, but unexpectedly, the samples tested showed signs of poor quality control. Upon investigation, it was discovered that a new supplier had introduced a new blend of fibers into the production process without proper testing protocols in place. The supplier's failure to disclose this change led to unintended variations in the fabric's properties, resulting in substandard products.

Results: The manufacturer took immediate action to address the issue, implementing stricter quality control measures and conducting additional testing to ensure compliance with international standards. As a result, subsequent samples passed all tests, restoring the brand's reputation and trust among consumers.

Conclusion: The testing process for Fairy Needle branded textiles is meticulous and rigorous, ensuring that every piece of clothing produced meets stringent safety and quality standards. By following a structured testing protocol and continuously improving upon existing processes, manufacturers can maintain their position as leaders in the textile industry. As more companies adopt similar practices, the overall quality of the industry will continue to improve, benefiting both consumers and the environment.

徐汇区仙女针纺织品检测概览

在美丽的徐汇区,我们见证了众多高质量的纺织品检测,我们将重点介绍一家名为“仙女针纺织品检测中心”的机构,为大家揭示其专业检测的奥秘。

仙女针纺织品检测的重要性

仙女针纺织品检测对于保障纺织品质量至关重要,通过严格的检测流程,确保每一件进入市场的纺织品都符合相关标准和法规要求,从而保障消费者的权益和安全,这也是推动纺织行业健康发展的重要手段。

检测流程与案例分析

检测流程:

(1)样品采集:从源头采集纺织品样品,确保样品具有代表性。 (2)样品检测:采用先进的检测设备和技术,对样品进行全面、细致的检测。 (3)结果出具:根据检测结果出具检测报告,明确纺织品的质量状况。

我们见证了一家知名品牌在徐汇区的纺织品检测过程,该品牌在采购过程中严格把关,确保所采购的纺织品符合国家标准,在经过严格的检测后,该品牌的产品获得了消费者的广泛好评,这不仅提升了品牌的市场竞争力,也为消费者提供了更安全、更可靠的购物保障。

案例分析:

(1)先进设备与技术:该中心使用的检测设备先进且专业,能够高效、准确地完成各项检测任务,采用先进的纤维分析仪、织物性能测试仪等设备,对纺织品进行全面的质量评估。 (2)严格把控质量标准:该中心对每一件进入市场的纺织品都严格把控质量标准,确保其符合相关标准和法规要求,还注重对样品采集的代表性,确保检测结果的准确性。 (3)客户反馈与市场表现:通过案例分析可以看出,该中心的产品深受消费者喜爱,市场表现良好,这不仅体现了该中心的专业性和可靠性,也为纺织行业的发展做出了积极贡献。

仙女针纺织品检测的未来展望

随着纺织行业的不断发展,仙女针纺织品检测中心将继续发挥重要作用,该中心将进一步加强检测能力建设,提高检测效率和质量,还将注重技术创新和人才培养,为纺织行业的发展提供更多支持,该中心还将积极响应国家政策,推动纺织行业的绿色发展,为保护环境、促进可持续发展做出贡献。

徐汇区仙女针纺织品检测中心以其专业的检测能力和严格的检测标准,为保障纺织品质量发挥了重要作用,该中心将继续发挥重要作用,为纺织行业的发展提供更多支持,我们也期待更多的机构加入到纺织行业的高质量发展中来,共同推动纺织行业的健康、可持续发展。

Articles related to the knowledge points of this article:

The Nature of Textiles:An Introduction to Their Classification and Application

The Rise of Textile Treasures:The Case of Pavilion Paper Tubes

The Luxury of LV Textile Coats

The Evolution and Impact of Shanghai Jia Ya Textiles Co.Ltd.