Textile Weft Deviation Control Requirements

: Textile Weft Deviation Control Requirements,In the textile industry, weft deviation control is a crucial aspect of ensuring the quality and consistency of fabrics. This process involves monitoring and managing the alignment of warp threads and their corresponding weft threads during the weaving process. Deviations in the weft direction can lead to uneven fabric patterns, poor fit, and reduced durability. Therefore, it is essential to implement strict control measures to minimize these issues.,The primary objective of weft deviation control is to maintain consistent warp-to-weft ratios throughout the fabric. This is achieved through the use of specialized tools and techniques that ensure accurate placement of the warp threads and their corresponding weft threads. Additionally, regular inspections and adjustments are necessary to address any deviations that may arise during the weaving process.,In conclusion, effective weft deviation control is critical for the production of high-quality textile products. By implementing strict control measures and using specialized tools and techniques, manufacturers can ensure consistent warp-to-weft ratios and minimize the occurrence of weft deviations.

Introduction: Textile production is a complex process that involves the manipulation of fibers to create fabric. One of the most critical aspects of this process is the control of weft deviation, which refers to the irregularity in the direction of the warp threads running along the length of the fabric. This deviation can result in defects such as creasing, pilling, and color bleeding, affecting both the aesthetic appeal and durability of the finished product. Therefore, it is essential to establish strict weft deviation control requirements to ensure consistent quality and meet industry standards. In this article, we will discuss the various factors that influence weft deviation and how they can be controlled through proper manufacturing processes and quality assurance measures.

Factors Affecting Weft Deviation: Weft deviation can be caused by several factors, including:

-

Material properties: The type and quality of the yarn used in the fabric play a significant role in determining weft deviation. High-quality yarn with uniform diameter and low twist will result in fewer weft deviations.

-

Yarn count: The number of yarns per inch (yarn count) also affects weft deviation. Lower yarn counts tend to produce less variation in the fabric due to the smaller number of threads.

-

Yarn structure: The arrangement of the yarns in the fabric can influence weft deviation. For example, using twisted yarns instead of straight ones can reduce the likelihood of weft deviations occurring.

-

Manufacturing techniques: The methods used to manipulate the yarn during the spinning process can also affect weft deviation. For instance, using a smoother spindle or adjusting the tension during the spinning process can minimize the occurrence of weft deviations.

-

Quality control measures: Proper quality control measures, such as regular inspections and testing, can help identify and address any issues before they become major problems.

Controlling Weft Deviation: To ensure consistent quality and meet industry standards, manufacturers must implement effective control measures for weft deviation. These measures include:

-

Selection of high-quality yarn: Using yarn with uniform diameter and low twist will reduce the likelihood of weft deviations occurring. It is important to select yarn that meets the required specifications and quality standards.

-

Yarn count optimization: Lower yarn counts tend to produce less variation in the fabric due to the smaller number of threads. Therefore, manufacturers should consider selecting yarn with a suitable yarn count that balances cost and quality.

-

Yarn structure adjustment: Using twisted yarns instead of straight ones can reduce the likelihood of weft deviations occurring. Additionally, adjusting the tension during the spinning process can improve the consistency of the fabric.

-

Quality control measures: Regular inspections and testing are essential to identify and address any issues before they become major problems. Manufacturers should establish quality control procedures that involve regular checks on yarn characteristics, yarn count, and other relevant parameters.

-

Training and education: Providing training and education to employees on the importance of weft deviation control and implementing appropriate training programs can help ensure compliance with industry standards and prevent errors from occurring.

Case Study: One example of successful weft deviation control is provided by the textile company, XYZ Corporation. XYZ employs a comprehensive approach to weft deviation control that includes the following steps:

-

Material selection: XYZ uses high-quality yarn with uniform diameter and low twist, ensuring consistent material properties throughout the production process.

-

Yarn count optimization: They have optimized their yarn count based on customer requirements and market trends, balancing cost and quality while maintaining consistent quality levels.

-

Yarn structure adjustment: By using twisted yarns in certain areas of the fabric, XYZ has reduced the occurrence of weft deviations and improved overall fabric quality.

-

Quality control measures: XYZ implements regular inspections and testing protocols to identify any issues early on and take corrective action promptly. They also provide ongoing training and education to their employees on weft deviation control and best practices for maintaining consistent quality.

Conclusion: The control of weft deviation is crucial for ensuring consistent quality and meeting industry standards in textile production. By selecting high-quality yarn, optimizing yarn count, adjusting yarn structure, implementing quality control measures, and providing training and education, manufacturers can effectively manage weft deviation and achieve optimal results. With these strategies in place, textile companies can confidently produce high-quality products that meet customer expectations and stand out in the competitive market.

纺织品在生产过程中,纬斜控制是一项重要的质量控制要求,纬斜不仅影响纺织品外观质量,还可能影响其尺寸稳定性、耐久性等性能,本文将详细阐述纺织品纬斜控制的要求,并通过案例分析来说明纬斜控制的重要性。

纺织品纬斜控制要求

定义与分类

纬斜控制要求纺织品在生产过程中,纬纱的直线度、角度偏差等控制在一定范围内,根据纬纱的来源和用途,纬斜控制可分为普通纬斜控制和特殊纬斜控制,普通纬斜控制适用于常规生产,而特殊纬斜控制则针对特定工艺或特殊需求进行控制。

控制标准

根据纺织品行业标准和规范,纬斜控制标准主要包括以下几个方面:

(1)直线度偏差:纬纱的直线度偏差应符合一定的标准范围。

(2)角度偏差:纬纱的角度偏差应控制在一定的角度范围内。

(3)尺寸稳定性:纬纱的尺寸稳定性应满足一定的要求,以保证纺织品在后续加工过程中的尺寸一致性。

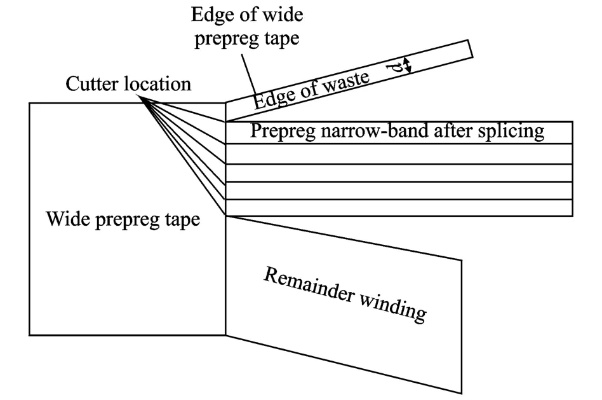

控制方法

(1)工艺控制:通过调整工艺参数,优化生产流程,减少纬纱的扭曲和变形。

(2)设备检测:采用先进的设备检测技术,对纺织品进行实时监测,及时发现和处理纬纱问题。

(3)人员培训:加强员工培训,提高员工对纬斜控制的认识和操作技能。

案例分析

以某纺织企业为例,该企业采用先进的纬纱控制系统,成功控制了纬斜问题,以下是该企业的纬斜控制案例分析:

生产工艺流程

该企业采用先进的织造工艺,包括织造、染整等环节,在织造过程中,采用自动化控制系统,实时监测纬纱的直线度和角度偏差,采用先进的设备检测技术,对纺织品进行实时监测,及时发现和处理纬纱问题。

纬斜控制实施过程

该企业在实施纬斜控制过程中,首先制定了详细的纬斜控制标准,通过工艺控制和设备检测相结合的方式,对生产过程中的纬纱进行实时监测和控制,在生产过程中,严格控制工艺参数,优化生产流程,减少纬纱的扭曲和变形,加强员工培训,提高员工对纬斜控制的认识和操作技能,该企业还采用了先进的设备检测技术,对纺织品进行深度检测和分析,及时发现和处理纬纱问题。

效果评估

经过实施纬斜控制后,该企业的纺织品质量得到了显著提升,纬纱的直线度和角度偏差得到了有效控制,尺寸稳定性得到了提高,该企业的生产效率也得到了显著提升,降低了生产成本,该企业的产品质量得到了客户的高度认可和好评。

纺织品纬斜控制是保证纺织品质量的重要要求之一,通过制定详细的纬斜控制标准、采用工艺控制和设备检测相结合的方式、加强员工培训等方式,可以有效控制纺织品纬斜问题,采用先进的设备检测技术,可以实现对纺织品的高效、精准检测和分析,在纺织生产过程中,应重视纬斜控制的要求,采取有效的措施和方法,确保纺织品的质量和性能。

Articles related to the knowledge points of this article:

The Evolution of Eastern Shopping and Donglong Textiles

Exploring the Rich Tapestry of Nontong Xinmei Yang Textiles