Strategies for Cost Control in Antimicrobial Textiles

Antimicrobial textiles have become increasingly popular in recent years, due to their ability to inhibit the growth of harmful bacteria and fungi. However, the production of these materials is often expensive, and cost control is a critical factor in their commercial viability. In this paper, we discuss various strategies for cost control in the production of antimicrobial textiles. These include the use of low-cost raw materials, the optimization of production processes, and the implementation of cost-effective packaging and distribution methods. We also explore the potential for using renewable resources in the production of these materials, which could further reduce costs. Overall, by implementing these strategies, it is possible to produce high-quality antimicrobial textiles at competitive prices, while still meeting the demands of consumers who prioritize safety and health.

Introduction: In the current global health climate, the demand for antimicrobial textiles has significantly increased. These materials are designed to resist bacterial and fungal growth, offering a significant benefit in healthcare settings such as hospitals, nursing homes, and medical equipment manufacturing. However, the production of these products often involves high costs due to the complexity of their manufacturing processes, which can be further exacerbated by the need to meet strict regulatory standards. In this article, we will discuss cost control strategies that can help reduce the overall production costs of antimicrobial textiles.

-

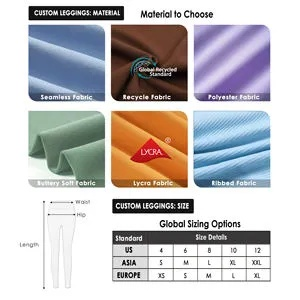

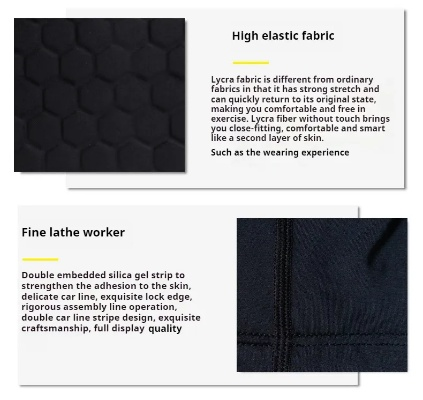

Material Selection: The choice of raw materials is crucial in determining the cost of antimicrobial textiles. Choosing materials with lower cost per unit weight and higher resistance to microbial growth can significantly reduce the overall production costs. For example, using natural fibers like cotton or linen instead of synthetic materials like polyester or nylon can reduce material costs without compromising the antimicrobial properties. Additionally, selecting materials that are more sustainable and eco-friendly can also contribute to reduced costs.

-

Production Process Optimization: Improving the efficiency of the production process can also lead to cost savings. This can include reducing waste during the manufacturing process, streamlining the assembly line, and implementing automation where possible. For instance, using computer-controlled machines that can perform multiple tasks simultaneously can save time and labor costs. Additionally, investing in research and development to improve the efficiency of existing processes can also result in cost savings.

-

Utilizing Technology: Advances in technology have made it possible to produce antimicrobial textiles at a lower cost. For example, using low-temperature methods for dyeing and finishing can reduce energy consumption and associated costs. Additionally, incorporating new technologies like nanotechnology into the production process can enhance the antimicrobial properties of the fabric without increasing the cost.

-

Regulatory Compliance: Regulatory compliance can also impact the cost of antimicrobial textiles. Companies must adhere to strict standards set by regulatory bodies, which can involve additional testing and certification processes. However, by understanding and complying with these regulations, companies can avoid costly penalties and fines. Additionally, having a robust quality control system in place can ensure that the final product meets all necessary standards, reducing the likelihood of recalls or lawsuits.

-

Supplier Relationship Management: Effective supplier management can also play a critical role in cost control. By negotiating favorable terms with suppliers and establishing strong relationships, companies can secure better pricing and negotiate discounts on bulk orders. Additionally, collaborating with suppliers to develop shared solutions for common issues can also help reduce costs and improve efficiency.

-

Employee Training and Development: Providing regular training and development opportunities for employees can help improve productivity and reduce costs. By ensuring that workers are equipped with the skills and knowledge needed to operate machinery and complete tasks efficiently, companies can minimize errors and wasted resources. Additionally, investing in employee retention can also help maintain a stable workforce and prevent downtime due to absenteeism.

-

Monitoring and Analysis: Continuous monitoring and analysis of production data can help identify areas where cost savings can be made. By tracking key performance indicators (KPIs) like labor hours per unit, material usage, and energy consumption, companies can identify areas where improvements can be made. Additionally, analyzing customer feedback and market trends can help inform future decisions about production processes and materials.

Conclusion: In conclusion, there are several cost control strategies that can be implemented to reduce the production costs of antimicrobial textiles. From material selection to technological advancements, each strategy has its own unique benefits. By implementing these strategies effectively, companies can not only reduce their production costs but also improve their competitiveness in the market. As the demand for antimicrobial textiles continues to grow, companies that adopt these cost control strategies will be well-positioned to succeed in the long run.

随着抗菌纺织品市场的不断扩大,成本控制成为企业发展的重要关键,本文将探讨抗菌纺织品成本控制的方法,并结合实际案例进行分析。

抗菌纺织品成本控制方法

材料采购成本控制

(1)严格筛选供应商,确保供应商具备良好的信誉和产品质量保证。

(2)制定合理的采购计划,避免库存积压和浪费。

(3)采用先进的成本控制手段,如合同管理、价格谈判等,降低采购成本。

生产过程成本控制

(1)优化生产工艺,提高生产效率。

(2)采用先进的生产设备和技术,提高生产质量。

(3)加强生产过程中的质量控制,确保产品质量符合标准。

研发成本控制

(1)加强研发团队建设,提高研发能力。

(2)采用先进的研发手段,降低研发成本。

(3)制定合理的研发计划,确保研发成果符合市场需求。

成本核算与分析

(1)建立完善的成本核算体系,对各项成本进行实时监控和分析。

(2)定期进行成本效益分析,评估成本控制效果。

(3)根据成本核算结果,制定相应的成本控制策略。

实际案例分析

以某抗菌纺织品生产企业为例,其成本控制的具体做法如下:

材料采购成本控制案例分析

该企业在材料采购过程中,严格筛选供应商,确保供应商具备良好的信誉和产品质量保证,制定了合理的采购计划,避免了库存积压和浪费,该企业还采用了先进的成本控制手段,如合同管理、价格谈判等,有效地降低了采购成本,最终实现了材料采购的高效性和成本控制的效果。

生产过程成本控制案例分析

该企业在生产过程中,优化生产工艺,采用先进的生产设备和技术,提高了生产效率和质量,加强了生产过程中的质量控制,确保产品质量符合标准,该企业还建立了完善的成本核算体系,对各项成本进行实时监控和分析,根据成本核算结果,该企业制定了一系列成本控制策略,包括优化生产流程、提高生产效率、降低生产成本等,这些策略的实施有效地控制了生产成本,提高了企业的经济效益。

抗菌纺织品成本控制是企业发展的重要关键,企业应该从材料采购、生产过程、研发成本控制等方面入手,采取有效的成本控制方法,企业还应该建立完善的成本核算体系,对各项成本进行实时监控和分析,以便更好地掌握成本控制情况,制定相应的成本控制策略,在实际操作中,企业应该根据自身情况选择合适的成本控制方法,并不断优化和完善成本控制策略。

Articles related to the knowledge points of this article:

Green Needlework Textiles Wholesale Prices in Lianyungang

Guide to the Best Location for Shanghai Textile Wholesale Market

Exploring the Rich Tapestry of Nontong Xinmei Yang Textiles

The Future of Fashion:Transforming Plastics into Superior Textiles

The Impediments of Limiting US Medical Textiles:A Comprehensive Analysis