The Future of Textiles in an Eco-Conscious Industry

The future of textiles in an eco-conscious industry is one that is characterized by sustainability, innovation, and responsible production practices. As consumers become increasingly aware of the impact of their choices on the environment, textile manufacturers are forced to reevaluate their supply chains and manufacturing methods. This shift towards sustainable textiles is driven by a growing recognition of the need to reduce our carbon footprint and protect natural resources.,One key area of focus is the use of renewable materials such as organic cotton, bamboo, and hemp. These materials are not only more environmentally friendly than traditional synthetic fibers but also offer unique properties that can enhance the performance of textiles. For example, bamboo is highly resistant to pests and has a lower environmental impact than cotton. Hemp, on the other hand, is a versatile crop that can be used for everything from clothing to paper and even biofuel production.,Another important trend is the development of circular economy models that prioritize waste reduction and recycling. This approach involves designing textile products with recyclable components and using innovative technologies to repurpose old textiles into new products. By reducing the amount of waste generated during the lifecycle of a textile product, manufacturers can significantly reduce their environmental footprint.,Overall, the future of textiles in an eco-conscious industry is one that is marked by innovation, sustainability, and responsible production practices. As consumers demand more from their clothing and accessories, it will be up to manufacturers to embrace these trends and create products that not only meet their needs but also contribute to a healthier planet.

In the world of textiles, we often focus on their practicality and aesthetic appeal. However, as our planet's environment continues to deteriorate, it's time for a shift towards a more sustainable approach to this industry. This talk will explore how textiles can be made more eco-friendly through innovative processes and materials, while still maintaining their quality and functionality. We'll also discuss some successful examples of companies that have taken steps towards reducing their environmental impact and making a positive impact on the planet.

At the heart of this discussion is the concept of "eco-textiles." These are fabrics that are designed to be more durable, reusable, and biodegradable than traditional textiles. By using natural fibers like cotton or linen, instead of synthetic ones like polyester or nylon, we can reduce our carbon footprint and decrease waste. Additionally, many eco-textiles are made from renewable resources, such as bamboo or hemp, which means they require less water and energy to produce than traditional textiles.

One example of an eco-textile company is Bamboo and Linen, a British company that specializes in producing sustainable clothing and home goods. They use organically grown bamboo and linen yarns, which are softer and more breathable than conventional materials. Their products are not only stylish but also environmentally friendly, making them a popular choice among consumers who care about both style and sustainability.

Another example is Patagonia, a US-based outdoor gear brand that has been at the forefront of promoting responsible fashion. They have developed a range of eco-friendly clothing and accessories that are made from recycled materials and organic cotton. Patagonia's commitment to sustainability extends beyond just their products; they also invest in research and development to find new ways to reduce their environmental impact.

However, despite these efforts, there is still much work to be done when it comes to making textiles more eco-friendly. Many textile industries rely heavily on fossil fuels for their production processes, which contribute to climate change and other environmental problems. To address this, companies must adopt more sustainable practices, such as using renewable energy sources and reducing waste during the manufacturing process.

Additionally, consumers have a role to play in shaping the future of textiles. By choosing products made from sustainable materials and supporting companies that prioritize sustainability, we can encourage industry leaders to continue investing in innovation and progress. It's important for consumers to educate themselves about the environmental impact of textiles and to make informed choices when shopping.

In conclusion, the future of textiles lies in a more sustainable and eco-conscious industry. By embracing eco-textiles and adopting more sustainable practices, we can create a better world for ourselves and future generations. As we move forward, let us continue to push for change and support those who are working towards a greener tomorrow.

随着全球环保意识的日益增强,纺织品行业正面临着转型升级的挑战,生态工业作为一种新型工业模式,旨在通过优化资源利用、减少环境污染、提高产业协同等方式,推动纺织业的可持续发展,本文将围绕纺织品生态工业的主题,探讨其发展现状、面临的挑战以及具体的实践案例。

纺织品生态工业的发展现状

政策支持与市场趋势

近年来,许多国家和地区都出台了相关政策,鼓励和支持纺织品生态工业的发展,随着消费者对环保、可持续性产品的需求增加,纺织品生态工业市场呈现出稳步增长的趋势。

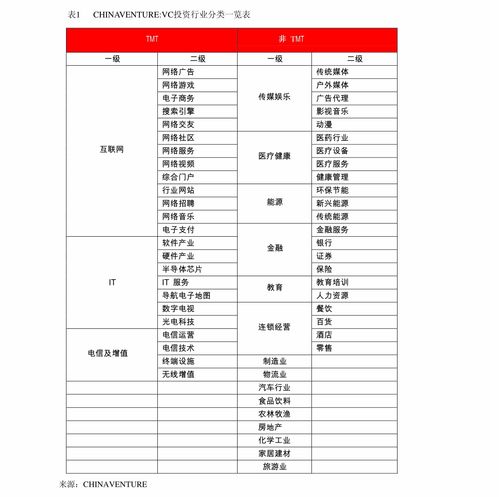

产业链构成

纺织品生态工业涉及多个产业链环节,包括纤维原料采集、纺织加工、染整、后处理、品牌营销等,纤维原料的可持续采集和高效利用是关键。

纺织品生态工业面临的挑战

资源限制与环境保护

纺织品生态工业面临着资源限制和环境保护两大挑战,有限的自然资源使得纺织品生产必须寻求更高效、可持续的利用方式;环境污染问题日益严重,需要加强环境保护和治理。

技术创新与产业协同

技术创新是纺织品生态工业发展的重要驱动力,产业协同方面仍存在不足,需要加强产业链上下游企业的合作与协同。

实践案例分析

以某知名纺织品品牌为例,其通过实施生态纺织技术,成功实现了资源的高效利用和环境保护,该品牌采用可持续纤维原料,优化纺织加工流程,减少废水、废气等污染物的排放,该品牌还加强了与上下游企业的合作,共同推动产业协同发展。

生态纺织技术的具体应用案例

纤维原料采集与可持续利用

该品牌采用先进的纤维原料采集技术,实现纤维原料的可持续利用,通过与农业合作社合作,采用有机种植方式采集纤维原料,减少了对环境的破坏,该品牌还推广使用环保染料和助剂,提高纺织产品的环保性能。

纺织加工过程中的环保措施

在纺织加工过程中,该品牌加强了废水、废气等污染物的处理和回收利用,采用先进的废水处理技术,减少废水排放;建立废气回收系统,回收利用废气中的有用成分,该品牌还加强了节能减排设备的投入和使用,降低能源消耗和碳排放。

纺织品生态工业是推动纺织业可持续发展的关键途径,通过实施生态纺织技术,实现资源的高效利用和环境保护,提高产业协同发展水平,政府和企业应加强政策支持、技术创新和产业协同等方面的努力,推动纺织品生态工业的发展,纺织品生态工业将继续面临更多的挑战和机遇,需要不断创新和进步。

Articles related to the knowledge points of this article:

The Strange Tale of the Textiles Towers Ghostly Residence