How to Determine the Structural Characteristics of Textile Fabrics

: Determining the Structural Characteristics of Textile Fabrics,Abstract:,The structural characteristics of textile fabrics are critical to understanding their properties and determining their suitability for specific applications. This paper outlines a methodology for identifying the key structural features of textile fabrics, including their density, thickness, weave pattern, and other relevant parameters. The analysis is based on various techniques such as visual inspection, densitometry, and mechanical testing, which provide a comprehensive understanding of the fabric's physical and mechanical properties. The findings from these analyses can be used to optimize the design of textile products, improve manufacturing processes, and enhance the overall performance of the fabrics. The study also highlights the importance of standardization in textile industry, as well as the potential for advancements in technology that could further improve the precision and efficiency of structural characterization.

Introduction: Textile fabrics are an essential part of our daily lives, from clothing and furnishings to industrial materials. The structural integrity of these fabrics is crucial for their functionality and longevity. In this guide, we will explore various methods to identify the different types of textile structures and how to use them to make informed decisions about the quality and suitability of a particular fabric.

Identifying the Type of Textile Structure The first step in determining the structural characteristics of a textile fabric is to identify its type. There are several ways to do this, including:

- Scientific Classification: Textiles can be classified based on their chemical composition, such as cotton, wool, polyester, etc. This classification helps to understand the fibers used in the fabric and their properties.

- Manufacturing Process: Different manufacturing processes result in different textures and finishes. For example, knitting produces a softer, more breathable fabric than weaving, which produces a stronger, smoother fabric.

- Color and Weave: Color and weave play a significant role in determining the structure of a textile fabric. For instance, a plain weave fabric has a uniform texture while a twill weave fabric has a diagonal pattern.

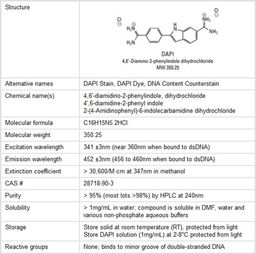

Using a Textile Structure Chart A table that outlines the different types of textile structures can be very helpful in identifying the structure of a fabric. Here's an example of a simple chart:

| Textile Structure | Description |

|---|---|

| Knitted Fabric | Made by interlocking loops of yarn, resulting in a smooth surface with a tighter structure. |

| Woven Fabric | Made by crossing threads at right angles, resulting in a more durable and sturdy structure. |

| Embroidered Fabric | Created by stitching small pieces of fabric together using a needle and thread, resulting in a unique pattern and texture. |

| Pleated Fabric | Created by folding over the edges of the fabric to create pleats or gathers, resulting in a more structured and finished look. |

Analyzing the Texture and Finish The texture and finish of a textile fabric are also important indicators of its structure. Here are some key factors to consider:

- Smoothness: A smooth fabric may have a higher degree of interlacing and less puckering, indicating a more complex structure.

- Texture: Texture refers to the way the fabric feels when touched, such as soft, rough, or coarse. Texture can be influenced by the fiber type, length, and density of the yarn.

- Finish: Finish refers to the final appearance of the fabric, such as glossy, matte, or brushed. Finish can be affected by the dyeing process and the application of finishing agents.

Testing the Strength and Durability To determine the structural strength and durability of a textile fabric, it is often necessary to conduct tests. Here are some common methods:

- Tensile Testing: This involves pulling a sample of the fabric through a machine until it breaks, measuring the force required to break it. A higher breaking strength indicates a more durable fabric.

- Burst Testing: This involves bursting the fabric into small pieces under pressure, measuring the amount of weight needed to break it. A lower burst strength indicates a more flexible fabric.

- Water Absorption Testing: This involves measuring the amount of water absorbed by the fabric, typically over a period of time. A higher absorption rate indicates a more absorbent fabric.

Case Study: Cotton Tweed Cotton tweed is a type of woven fabric made from a tightly spun yarn. It has a distinct texture and finish due to the twisting of the yarn during the weaving process. To determine its structural characteristics, one could use the table above to identify its type and then analyze its texture and finish using techniques like tensile testing and burst testing.

Conclusion: By utilizing scientific classification, manufacturing processes, color and weave, and other relevant factors, we can effectively identify the structural characteristics of textile fabrics. Additionally, analyzing the texture and finish, and conducting strength and durability tests can provide valuable insights into the quality and suitability of a particular fabric. With this knowledge, consumers can make more informed decisions when selecting textile products.

在日常生活中,我们经常接触到各种各样的纺织品,从日常衣物到高端服装,为了更好地了解纺织品,掌握其组织结构是非常重要的,我们就来探讨一下如何判断纺织品组织结构。

了解纺织品的基本知识

纺织品主要由纤维、纱线、织物等基本元素组成,纤维是纺织品的骨架,决定了其强度和耐用性;纱线则是将纤维连接起来的细线,决定了织物的纹理和厚度;织物则是将纱线紧密编织而成的整体。

判断纺织品组织结构的步骤

观察纤维类型和含量

观察纺织品的纤维类型和含量是判断其组织结构的基础,不同的纤维类型和含量会影响织物的强度、柔软度、吸湿性等特性,棉纤维通常比较柔软、吸湿性好,适合制作夏季衣物;而涤纶纤维则比较结实、耐用,适合制作工业用品。

分析纱线的粗细和密度

纱线的粗细和密度也是判断纺织品组织结构的重要依据,纱线的粗细决定了织物的厚度和纹理,而密度则决定了织物的强度和耐用性,在纺织过程中,纱线的加工工艺和设备会影响纱线的粗细和密度。

观察织物的纹理和结构

织物的纹理和结构也是判断纺织品组织结构的重要依据,不同的织物有不同的纹理和结构,例如平纹织物、斜纹织物等,平纹织物通常比较柔软、透气,适合制作夏季衣物;而斜纹织物则比较结实、耐磨,适合制作工业用品。

案例说明

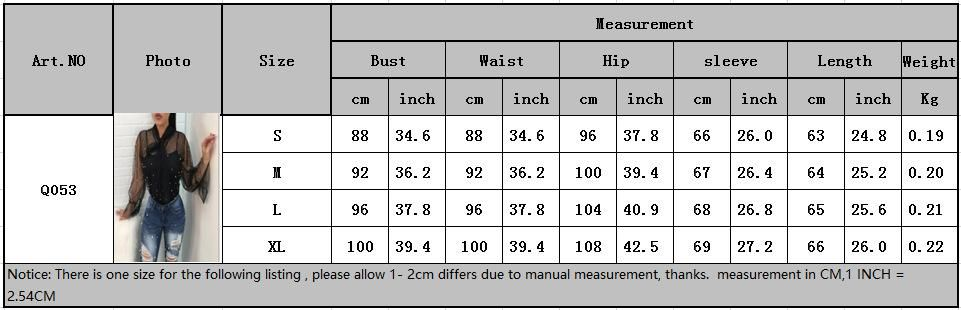

以纺织品为例,我们可以使用英文表格来进一步说明如何判断纺织品组织结构。

纺织品类型与组织结构对应关系

| 纺织品类型 | 纤维类型 | 纱线类型 | 组织结构 | 特点描述 |

|---|---|---|---|---|

| 棉质衣物 | 天然棉纤维 | 普通纱线 | 平纹织物 | 柔软、吸湿性好 |

| 涤纶工业用品 | 合成涤纶纤维 | 高密纱线 | 斜纹织物 | 结实、耐用 |

| 丝绸衣物 | 丝绸纤维 | 特殊纱线 | 细腻纹理 | 柔软、光泽好 |

通过上述案例,我们可以看出不同种类的纺织品其组织结构是不同的,棉质衣物通常采用平纹织物,这是因为棉纤维柔软、吸湿性好;而涤纶工业用品则采用斜纹织物,这是因为涤纶纤维结实、耐用,不同的纱线类型也会影响织物的纹理和结构,在购买纺织品时,了解其组织结构是非常重要的。

判断纺织品组织结构需要从纤维类型和含量、纱线的粗细和密度以及织物的纹理和结构等方面进行综合考虑,通过观察纺织品的基本知识以及案例说明,我们可以更好地了解纺织品组织结构,从而更好地选择适合自己的纺织品,在购买纺织品时,也可以根据其组织结构来选择适合自己的产品。

Articles related to the knowledge points of this article:

The Beauty of Textiles in Jinzhou City

Protecting Your Home with the Power of Antimicrobial Guangzhou Textiles