The Role of Dyeing in Textiles:A Comprehensive Guide

Dyeing is an essential process in the production of textiles, which involves applying dyestuffs to fabrics to produce a desired color. This article provides a comprehensive guide on the role of dyeing in textiles, covering various aspects such as dyeing techniques, factors affecting dye uptake, and the importance of quality control during dyeing processes. It also discusses the environmental impact of dyeing and the potential for sustainable alternatives to traditional dyeing methods. Overall, this guide aims to help readers understand the complexities of dyeing and how it contributes to the overall production of textiles.

Dyeing is a crucial step in the manufacturing process of textiles, as it not only enhances the aesthetic appeal of garments but also adds functionality and durability to fabrics. In this guide, we will explore the various reasons why dyeing is essential for textiles and how it contributes to their end-use performance. We will also present an overview of the different types of dyes used in textile dyeing, their applications, and the challenges faced by manufacturers when selecting and applying these dyes. Finally, we will provide insights into some real-world cases where dyeing has played a significant role in shaping the industry.

I. Understanding the Importance of Dyeing

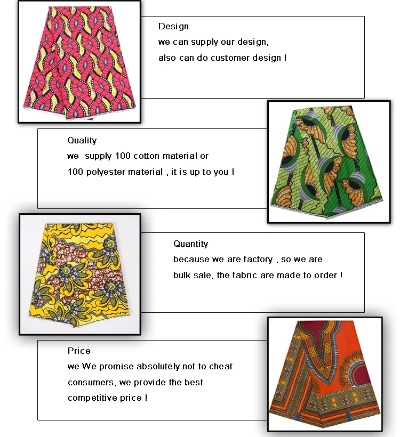

Textile dyeing is an essential process that involves applying colorants to fabrics to create patterns, designs, and colors. This process is crucial because it allows manufacturers to customize products to meet specific market demands, enhance brand recognition, and improve product quality. By using dyes, manufacturers can achieve a wide range of effects, including vivid hues, subtle gradients, and intricate patterns. Additionally, dyeing provides textiles with resistance to soiling, fading, and wear and tear, making them more durable and long-lasting.

II. Different Types of Dyes Used in Textile Dyeing

There are several types of dyes used in textile dyeing, each with its unique characteristics and applications. Here's a table outlining some of the most common dyes and their uses:

| Dye Type | Application |

|---|---|

| Direct dyes | Apply directly onto fabric without pretreatment |

| Indirect dyes | Apply after pretreatment, such as scouring or bleaching |

| Ester dyes | Use ester groups to attach the dye to the fabric |

| Azo dyes | Use azo groups to bind the dye to the fabric |

| Reactive dyes | Use reactive groups to react with the fabric during dyeing |

| Metal complex dyes | Use metal complexes to attach the dye to the fabric |

III. Challenges in Dyeing Manufacturing

While dyeing offers numerous benefits, manufacturers must also contend with several challenges in achieving optimal results. These include:

- Colorfastness: Ensuring that dyed fabrics maintain their color and appearance over time is crucial for consumer satisfaction.

- Recognition: Manufacturers must ensure that their products meet certain standards to gain recognition from buyers and consumers.

- Cost Control: Reducing costs while maintaining quality and ensuring compliance with regulations is a major challenge.

- Environmental Impact: Manufacturers must consider the environmental impact of their dyeing processes, including waste management and energy consumption.

- Technology Advancements: Keeping up with new technologies and innovations can help manufacturers stay ahead of the competition and improve their products.

IV. Case Study: The Role of Dyeing in Fashion Industry

One example of the importance of dyeing in the fashion industry is the use of colored yarns in knitwear. For instance, a company may use a combination of direct and indirect dyes to create vibrant and long-lasting patterns on sweaters. Another example is the use of metallic dyes in high-end fashion accessories, which add a touch of elegance and sophistication to garments such as hats, belts, and jewelry.

In conclusion, dyeing plays a vital role in the manufacturing process of textiles. It not only enhances the aesthetic appeal of garments but also adds functionality and durability to fabrics. By understanding the different types of dyes used in textile dyeing and the challenges faced by manufacturers, we can better appreciate the importance of this process in shaping the fashion industry.

背景介绍

纺织品染色是纺织行业中的重要环节,它涉及到纺织材料的加工、整理和美化,随着人们对生活品质和时尚追求的不断提高,纺织品染色行业也得到了快速发展,本文将从多个角度探讨纺织品染色的必要性及其背后的原因。

纺织品染色的重要性

满足市场需求

随着全球纺织品的不断更新换代,消费者对于纺织品的要求也越来越高,纺织品染色可以满足不同消费者的需求,提高产品的附加值和市场竞争力。

提升产品品质

纺织品染色可以改善纺织品的色泽、手感、耐久性等品质指标,提高产品的档次和品质,染色技术还可以增加纺织品的多样性和个性化,满足不同消费者的需求。

环保理念推动

随着环保意识的不断提高,纺织品染色行业也在积极推广环保理念,采用环保染料和染色技术可以减少环境污染,符合现代社会对绿色、低碳、可持续发展的要求。

纺织品染色的原因

市场需求变化

随着人们生活水平的提高和时尚追求的不断升级,人们对纺织品的要求也越来越高,不同国家和地区的文化差异也使得纺织品呈现出多样化的特点,纺织品染色行业得到了快速发展。

技术进步推动

随着纺织技术的不断进步,染料和染色技术也得到了不断更新和改进,新型染料具有更好的色泽、更好的耐久性、更环保等特点,使得纺织品染色更加高效、环保,染色技术的不断创新也使得纺织品更加美观、个性化。

案例分析

以某知名品牌为例,该品牌在纺织品染色方面采用了先进的染色技术和环保染料,使得产品的色泽更加鲜艳、手感更加舒适、耐久性更加优良,该品牌还注重产品的个性化设计和环保理念,使得产品更加符合现代消费者的需求。

纺织品染色的过程及案例说明

过程说明

纺织品染色过程主要包括原料准备、染色工艺制定、染色操作等环节,在原料准备阶段,需要选择合适的染料和颜料;在染色工艺制定阶段,需要根据纺织品的材质、颜色要求等制定合适的染色工艺;在染色操作阶段,需要按照染色工艺进行操作,确保染色的效果和质量。

案例说明

以某知名品牌的一款新型面料为例,该面料采用了先进的染色技术和环保染料,使得产品的色泽更加鲜艳、手感更加舒适、耐久性更加优良,该品牌还注重产品的个性化设计和环保理念,使得产品更加符合现代消费者的需求,该品牌还采用了多种环保材料和技术手段,提高了染色的效率和环保性,该品牌采用了生物酶染色技术,该技术可以减少废水排放和对环境的影响;采用了无毒染料和环保染料,使得产品在使用过程中更加安全可靠,这些案例说明纺织品染色的重要性及其在纺织行业中的广泛应用。

纺织品染色是纺织行业中的重要环节,它涉及到纺织材料的加工、整理和美化,随着人们对生活品质和时尚追求的不断提高,纺织品染色行业也得到了快速发展,我们需要加强对纺织品染色的重视和研究,不断提高染色的效果和质量,满足市场需求和环保理念的要求。

Articles related to the knowledge points of this article: