The Art of Packing and Compressing Textiles for Optimal Transport

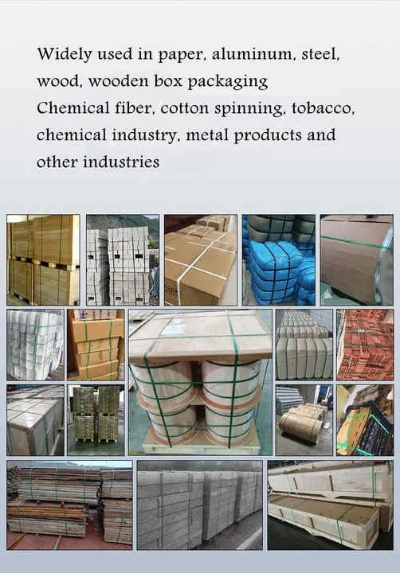

"The Art of Packing and Compressing Textiles for Optimal Transport: A Comprehensive Guide",In the realm of textile transportation, efficient packing and compression methods are crucial for maximizing cargo capacity and reducing transportation costs. This guide aims to provide textile industry professionals with a comprehensive understanding of the techniques used to pack and compress textiles for optimal transport.,The first step in this process is to select the appropriate packaging materials, such as polyethylene or polypropylene film, which can effectively protect textiles during transport. Once the packaging materials have been selected, the next step is to determine the appropriate dimensions and shape for each piece of textile. This will depend on factors such as the weight and size of the textile, as well as the intended destination and mode of transportation.,Once the dimensions and shape of the textile have been determined, the next step is to apply pressure to the packaging material using specialized equipment such as compression machines or manual tools. This process is essential in order to create a strong seal between the textile and the packaging material, ensuring that it remains securely in place during transit.,In conclusion, packing and compressing textiles for optimal transport requires careful consideration of various factors, including the selection of appropriate packaging materials, determination of the appropriate dimensions and shape for each piece of textile, and application of pressure using specialized equipment. By following these steps, textile industry professionals can ensure that their products are safely transported from one location to another while minimizing transportation costs.

Introduction: Packing and compressing textiles is a crucial step in the fabrication process, as it helps to reduce the weight, volume, and enhances the durability of the finished product. This article will discuss the various techniques used in packing and compressing textiles, including their benefits, methods, and practical applications. We'll also present an example of how these techniques can be applied in a real-world scenario.

Benefits of Packing and Compression: Packing and compression are essential for several reasons:

- Weight Reduction: By reducing the weight of textiles, they become easier to transport and handle. This is particularly important for bulky or heavy items that require special handling.

- Volume Reduction: Compression reduces the size of textiles by removing air spaces and water content. This makes them more compact and easier to store or transport.

- Durability: Compression can improve the resilience of textiles by reducing the amount of wear and tear caused by external factors such as moisture, dust, and sunlight.

- Cost-Effectiveness: Reducing the weight and volume of textiles can significantly reduce transportation and storage costs. It also saves energy and resources during production and distribution.

- Environmental Sustainability: Compression can help reduce the carbon footprint associated with shipping textiles, as less energy is required to transport them.

Methods of Packing and Compression: There are several methods used in the packing and compression of textiles:

- Rolling: One common method is to roll the textiles tightly together using a roller. This technique reduces the volume and weight of the textiles while maintaining their shape and integrity.

- Stuffing: Another method involves stuffing the textiles with small fillers such as sand, sawdust, or shredded paper. This reduces the volume of the textiles without altering their shape.

- Tape Seal: A layer of tape or plastic wrap can be used to seal the edges of the textiles to prevent air leakage and maintain moisture control.

- Bubble Wrap: Bubble wrap or polystyrene foam is often used to cushion the textiles during transportation. It provides extra protection against impacts and vibrations.

- Containerization: Specialized containers designed for textiles can be used to transport them safely and efficiently. These containers provide a protective environment that keeps the textiles dry and protected from damage.

Practical Applications: Packing and compression techniques can be applied in various industries, including textile manufacturing, logistics, and retail. Here are some examples:

- In textile manufacturing, compression techniques are used to produce high-quality fabrics that meet specific standards. For example, garment manufacturers may use compression to create smoother, more uniform fabrics.

- In logistics, packing and compression techniques are crucial for ensuring the safe delivery of textiles. For instance, airlines may use specialized packaging materials to protect fragile textiles during transit.

- In retail, compression techniques can be used to store textiles in warehouses or stores. For example, clothing retailers may use vacuum-sealed bags to keep clothes fresh and prevent wrinkling.

Case Study: One example of how packing and compression techniques can be applied in a real-world scenario is the case of a textile manufacturer who produces high-quality carpets for residential use. To ensure the safety and quality of the carpets during transportation, the manufacturer employs several compression techniques:

- The carpets are rolled up tightly using a roller to reduce their volume and weight.

- Small fillers such as sawdust are added to the rolls to further reduce the volume of the carpets.

- A layer of bubble wrap is placed on top of the rolled carpets to cushion them during transportation.

- Specialized containers are used to transport the carpets safely and efficiently. These containers provide a protective environment that keeps the carpets dry and protected from damage.

Conclusion: Packing and compression techniques are essential for ensuring the quality, safety, and cost-effectiveness of textile products. By following proper techniques, manufacturers can reduce the weight and volume of textiles while maintaining their shape and integrity. Industrial and retail sectors can benefit from these techniques by improving the efficiency and sustainability of their operations. As technology continues to evolve, we can expect even more innovative solutions to emerge in this field, further enhancing the performance and effectiveness of textile packaging and compression.

纺织品打包压缩概述

随着现代物流业的快速发展,纺织品打包压缩已成为确保货物安全、快速运输的关键环节,本文将围绕纺织品打包压缩的主题,从多个角度展开讨论。

纺织品打包压缩的流程

- 材料准备:根据货物的特性和运输需求,选择合适的打包材料,这可能包括各种纤维材料、填充物等。

- 设计打包方案:根据货物的形状、尺寸和重量,设计合理的打包方案,确保打包过程既高效又安全。

- 压缩处理:使用专业的压缩设备对纺织品进行压缩处理,以减少体积并提高运输效率。

- 包装固定:使用适当的包装材料和工艺,将纺织品固定在适当的位置,确保其在运输过程中不易散落或破损。

案例分析

以下是一个纺织品打包压缩的案例说明:

某大型纺织品公司为了提高运输效率,采用了先进的打包压缩技术,该公司根据货物的特性和运输需求,选择了高质量的打包材料,并设计了合理的打包方案,在压缩处理过程中,该公司使用了高效的压缩设备,确保了纺织品在短时间内得到有效的压缩,该公司的纺织品被安全、快速地打包压缩后,成功运往目的地。

在纺织品打包压缩过程中,考虑到不同纤维材料的特性差异,该公司采用了不同的填充物进行填充,对于柔软的纤维材料,该公司使用了柔软的填充物进行填充,以确保纺织品在运输过程中不易变形或破损,该公司还采用了先进的包装固定技术,确保纺织品在运输过程中不易散落或脱落,通过这些措施,该公司的纺织品打包压缩工作取得了良好的效果。

纺织品打包压缩的技术要点

- 选择合适的打包材料:根据货物的特性和运输需求,选择高质量、环保、可降解的打包材料。

- 设计合理的打包方案:根据货物的形状、尺寸和重量,设计合理的打包方案,确保打包过程既高效又安全。

- 使用专业的压缩设备:使用专业的压缩设备对纺织品进行压缩处理,以减少体积并提高运输效率,注意设备的维护和保养,确保其正常运行。

- 注意包装固定工艺:使用适当的包装材料和工艺,将纺织品固定在适当的位置,确保其在运输过程中不易散落或破损,还可以采用防震、防潮等特殊工艺,进一步提高纺织品在运输过程中的稳定性。

英文表格补充说明

以下是一个英文表格来补充说明纺织品打包压缩的相关内容:

| 术语 | 定义 | 示例说明 |

|---|---|---|

| 纺织品打包材料 | 用于包装纺织品的材料 | 如棉布、丝绸等 |

| 打包方案设计 | 根据货物特性和运输需求制定的包装方案 | 根据形状、尺寸和重量进行设计 |

| 压缩处理设备 | 用于对纺织品进行压缩处理的设备 | 如压缩机、打包机等 |

| 压缩效果评估 | 通过减少体积和提高运输效率来评估压缩效果 | 可以通过测量体积、重量等指标进行评估 |

| 案例分析示例 | 一个大型纺织品公司的案例分析 | 该公司在采用先进的打包压缩技术后,成功提高了运输效率 |

纺织品打包压缩是现代物流业中不可或缺的一环,通过选择合适的打包材料、设计合理的打包方案、使用专业的压缩设备以及注意包装固定工艺等措施,可以有效提高纺织品在运输过程中的稳定性和安全性,在实际操作中,还需要注意设备的维护和保养,以确保其正常运行和提高工作效率。

Articles related to the knowledge points of this article:

Red Manufacturers Textiles:Innovating Traditional Craftsmanship

The Global Fabric of Innovation:An Exploration into Lu Xu Textiles

The Dynamics of Sustainable Fashion:An Exploration into Lichuang Textile