The Art of Textile Quality Inspection:A Comprehensive Guide

"The Art of Textile Quality Inspection: A Comprehensive Guide" is a comprehensive guide to the art of textile quality inspection. The book provides an in-depth understanding of the various techniques and tools used in the inspection process, including visual inspection, mechanical testing, and laboratory analysis. It covers topics such as color consistency, pattern accuracy, stitching strength, and fabric texture, among others.,The book also discusses the importance of proper inspection procedures and how they can impact the overall quality of the textile product. It emphasizes the need for thorough documentation and reporting to ensure that any defects or issues are identified and addressed promptly.,Overall, "The Art of Textile Quality Inspection: A Comprehensive Guide" is a valuable resource for anyone involved in the textile industry, whether they are manufacturers, retailers, or consumers. With its extensive knowledge and practical guidance, it provides a comprehensive overview of the inspection process and helps readers achieve high levels of textile quality.

Introduction: In the world of textile manufacturing, quality is not just a buzzword; it's the backbone of success. Whether you're a manufacturer or an importer, understanding how to properly inspect and assess the quality of your raw materials—like the fabric called "textile"—is crucial for maintaining consistent product standards and customer satisfaction. In this guide, we'll dive into the intricacies of textile quality inspection, including the tools, techniques, and best practices that can help you achieve top-tier results.

Textile Quality Inspection Tools:

-

Scientific Instruments: These are the heavy lifters of quality control. They include instruments like calipers, densitometers, and digital microscopes. For example, a caliper can measure the thickness of a fabric, while a densitometer can analyze its density to check for uniformity.

-

Computerized Testing Machines: These machines are designed to perform complex tests on fabric samples. They can simulate different weather conditions, such as washing, drying, and exposure to sunlight, to evaluate the fabric's durability.

-

Chemical Analyzers: These tools help identify any harmful substances or contaminants in the fabric. For instance, they can detect traces of dyes, chemicals, or pesticides that might compromise the fabric's safety or performance.

-

Optical Instruments: These devices use light to examine the texture and pattern of the fabric. They can reveal flaws like holes, tears, or discoloration.

-

Digital Image Analysis Software: This software allows technicians to quickly and accurately analyze images captured by various instruments. It can help identify patterns, color variations, and other features that might affect the fabric's quality.

-

Laboratory Testing Kits: These kits contain all the necessary chemicals and reagents for conducting specific tests on the fabric. For example, a test kit for measuring flame resistance can be used to determine if the fabric meets industry standards.

Textile Quality Inspection Techniques:

-

Visual Inspection: This is the most basic but still essential method of quality control. Technicians use their eyes to examine the fabric for defects like holes, tears, or discoloration.

-

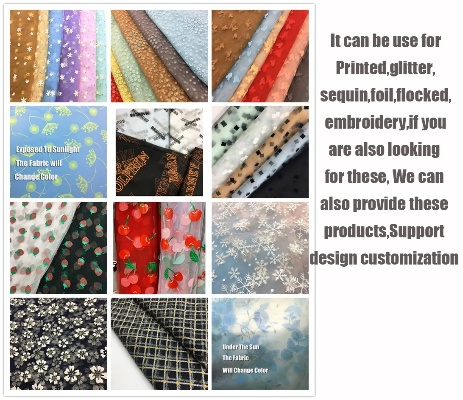

Dye Testing: This test involves placing a small sample of the fabric under a UV lamp to see if the dye has faded or changed color over time. This helps identify any degradation in the fabric's chemical composition.

-

Press Testing: This test simulates the fabric's handling during production and shipping. It involves pressing the fabric against a flat surface to see if it retains its shape and color after being pressed.

-

Wash Testing: This test mimics the fabric's exposure to water and detergent during washing processes. It involves placing a small sample of the fabric in a washing machine and running it through a series of cycles to see if it loses its color or becomes damaged.

-

Burst Testing: This test measures the fabric's strength and durability. It involves squeezing the fabric between two plates until it bursts, indicating its ability to withstand stress.

-

Burn Testing: This test measures the fabric's resistance to fire. It involves heating a small sample of the fabric and observing its behavior under heat.

-

Electrical Resistance Testing: This test measures the fabric's electrical conductivity. It involves passing a current through the fabric and measuring the resistance to determine its ability to conduct electricity.

-

Mechanical Testing: This includes testing the fabric's flexibility, strength, and resistance to tearing. It involves using specialized equipment to measure the fabric's properties under different conditions.

-

Odor Testing: This test measures the fabric's smell. It involves placing a small sample of the fabric in a sealed container and exposing it to air for a set period to see if it develops any odor.

-

Compression Testing: This test measures the fabric's ability to resist creasing or wrinkling when placed under pressure. It involves compressing the fabric between two plates and measuring the difference in height before and after compression.

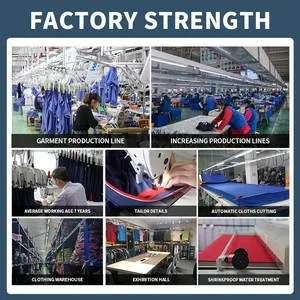

Case Study: Imagine you're working at a textile company that specializes in producing high-quality sportswear. Your team is responsible for inspecting the fabric used in these garments. You decide to implement a comprehensive quality control system that includes both visual inspection and scientific testing.

First, you establish a standard protocol for visual inspection, ensuring that all samples meet certain criteria before moving on to more rigorous tests. Then, you use dye testing to ensure that the fabric doesn't fade over time. Next, you perform press testing to ensure that the fabric maintains its shape and color after being pressed.

You also conduct wash tests to ensure that the fabric remains vibrant after multiple washings. Additionally, you use burn testing to assess the fabric's fire resistance. Finally, you conduct electrical resistance testing to ensure that the fabric is suitable for electronic components.

By following this comprehensive approach, your team can detect any potential issues early on and address them before they impact the final product. This not only improves the quality of your products but also enhances customer satisfaction and loyalty.

Conclusion: Quality control is an ongoing process that requires constant refinement and adaptation. By incorporating scientific tools and advanced techniques into your inspection process, you can ensure that your textile products meet or exceed customer expectations. Remember, every detail counts when it comes to creating exceptional textiles that stand out from the competition. So, let's embrace the art of textile quality inspection and deliver nothing but excellence!

在纺织品生产过程中,坯布的质量直接关系到最终产品的品质和消费者的使用体验,对纺织品坯布的质量进行严格检测是确保产品质量的重要环节,本报告将详细介绍纺织品坯布质量检测的方法、流程及案例分析。

坯布质量检测方法

外观检查

外观检查是坯布质量检测的基础环节,主要检查坯布的色泽、纹理、纤维含量等外观特征,通过观察和手感,判断坯布的质地是否均匀、有无瑕疵。

密度测试

密度测试是衡量坯布厚度和密实度的关键指标,可以采用密度计或称重法等方法进行测试,通过测量不同厚度和密实的坯布样品,评估其密度是否符合标准。

化学成分分析

对坯布进行化学成分分析,可以了解其纤维类型、含量以及染色牢度等,可以采用各种化学分析方法,如元素分析、纤维分析等,对坯布进行全面检测。

机械性能测试

机械性能测试包括拉伸强度、撕裂强度、耐磨性等,可以评估坯布的机械性能是否符合要求,可以采用各种机械性能测试仪器进行测试,如拉力试验机、耐磨试验机等。

坯布质量检测流程

-

材料准备:准备检测所需的样品、工具和设备。

-

外观检查:对样品进行外观检查,记录检查结果。

-

密度测试:使用密度计或称重法等方法对样品进行密度测试,记录测试结果。

-

化学成分分析:对样品进行化学成分分析,记录分析结果。

-

机械性能测试:根据测试需求选择合适的机械性能测试仪器,对样品进行机械性能测试。

-

数据整理:将检测数据整理成表格,便于查阅和分析。

案例分析

以某纺织企业为例,对其纺织品坯布质量检测进行案例分析,该企业生产的纺织品坯布主要采用天然纤维材料,经过多道工序加工而成,在质量检测过程中,采用了多种方法进行检测,取得了较好的效果。

-

外观检查:对该企业生产的纺织品坯布进行了外观检查,发现色泽均匀,纹理清晰,无明显瑕疵。

-

密度测试:对该企业生产的纺织品坯布进行了密度测试,发现其密度符合标准要求,该企业使用的密度计精度高,操作简便,测试结果准确可靠。

-

化学成分分析:对该企业生产的纺织品坯布进行了化学成分分析,发现其主要采用天然纤维材料,纤维含量符合标准要求,染色牢度也符合要求,该企业的染色工艺稳定可靠,染色效果良好。

-

机械性能测试:对该企业生产的纺织品坯布进行了拉伸强度、撕裂强度、耐磨性等机械性能测试,结果表明,该企业的纺织品坯布机械性能符合要求,具有较好的抗拉强度和耐磨性。

通过对纺织品坯布质量检测的方法、流程及案例分析,可以看出,对纺织品坯布的质量进行严格检测是确保产品质量的重要环节,在检测过程中,需要采用多种方法进行综合检测,以确保坯布的质量符合标准要求,还需要不断改进检测技术和方法,提高检测的准确性和可靠性。

Articles related to the knowledge points of this article:

The Evolution and Impact of Shaoxing Yifeng Textiles

Transforming the Textile Landscape:The Story of Tongxiang AoLur Textiles

The Multifaceted World of Navier Textiles:A Comprehensive Guide

Fabric Testing in Wuxi A Journey Towards High-Quality Textiles