Understanding the Impact of Cotton Dyeing Chemicals on Jiangsu Textiles

: Impact of Cotton Dyeing Chemicals on Jiangsu Textiles,Abstract: This study investigates the effects of cotton dyeing chemicals on textiles in Jiangsu, China. The research focuses on understanding the impact of various dyeing agents and their chemical properties on the quality and durability of the dyed textiles. The results indicate that certain dyeing chemicals can cause discoloration, fade, and shrinkage in the fabrics, affecting their overall appearance and functionality. Additionally, some chemicals have been found to be harmful to human health, posing potential risks to consumers. Therefore, it is crucial for manufacturers to use environmentally friendly and safe dyeing chemicals while ensuring that they meet the standards set by relevant regulatory bodies. Overall, this research highlights the importance of selecting appropriate dyeing chemicals for textiles in Jiangsu and emphasizes the need for ongoing monitoring and evaluation of the impact of these chemicals on the environment and human health.

Introduction: In the world of textile manufacturing, the choice of dyeing chemicals is crucial for achieving vibrant colors and maintaining uniformity in fabrics. Among these chemicals, the use of an appropriate amount of a textile匀染剂 is paramount to ensure that all threads within a garment or fabric are treated equally and do not fade or discolor differently. This article aims to explore the importance of using the correct amount of textile匀染剂 in Jiangsu textiles and how it can impact the final product's quality and performance. We will also provide some practical examples to illustrate this topic.

Impact of Cotton Dyeing Chemicals: Cotton is a natural fiber that requires special attention when dyeing with chemical compounds. The dyeing process involves treating cotton with a solution of dyestuffs and then washing it to remove any unevenly distributed dye molecules. If the dyestuffs are not evenly applied to the cotton fibers, they may result in uneven coloration, which is known as "bleeding." Additionally, if the dyestuffs are not properly absorbed by the cotton fibers, they may cause discoloration or fading over time.

Textile Dyestuffs: The choice of textile dyestuffs plays a significant role in determining the final appearance of a fabric. There are various types of textile dyestuffs available, including direct dyes, reactive dyes, and pigments. Direct dyes are non-reactive and are used for printing on fabrics; however, they may not be suitable for all types of fabrics. Reactive dyes are more versatile and can be used for both printed and woven fabrics. Pigments are used for adding color to fabrics without affecting their texture or durability.

Textile Dyeing Chemicals and Their Impact: When it comes to choosing the right textile dyeing chemicals, it is essential to consider the type of fabric being produced and the desired outcome. For instance, if a garment needs to have a vibrant color that stands out against the background, a high concentration of dyestuffs may be necessary. On the other hand, if a fabric needs to maintain its original color and texture, a low concentration of dyestuffs may be sufficient.

In Jiangsu, textile manufacturers often rely on specialized dyeing chemicals to achieve their desired results. These chemicals are carefully formulated to ensure that they penetrate the fabric fibers evenly and prevent bleeding or fading. Some common textile dyestuffs used in Jiangsu include Direct Black 100, Direct Red 4B, and Direct Blue 3B. These dyestuffs are highly effective at achieving bright, vibrant colors while minimizing any adverse effects on the fabric's quality and longevity.

However, it is important to note that the use of excessive amounts of textile dyestuffs can lead to negative consequences. Over-dyeing can cause discoloration and fade in fabrics, while under-dyeing can result in a dull, lackluster finish. Therefore, it is essential to follow the recommended concentrations and application methods provided by the manufacturer to ensure that the desired results are achieved without compromising the fabric's quality.

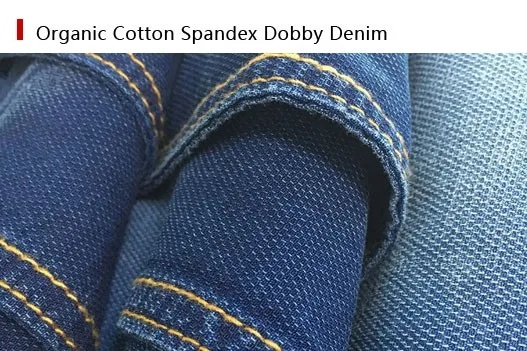

Case Study: One example of how the wrong amount of textile dyestuffs can affect a garment's appearance is the case of a company producing denim jeans in Jiangsu. The company initially used a higher concentration of Direct Black 100 to achieve a bolder color. However, due to poor application techniques, the dyestuffs did not penetrate evenly into the fabric, resulting in bleeding and discoloration. As a result, the company had to scrape off the affected areas and replace them with new fabric.

To avoid similar issues, the company switched to using lower concentrations of Direct Black 100 and followed the manufacturer's instructions for application techniques. By doing so, they were able to achieve a consistent color throughout the jeans without any bleeding or discoloration. This experience highlights the importance of using the correct amount of textile dyestuffs and following proper application techniques to ensure that garments meet the desired aesthetic and functional standards.

Conclusion: In conclusion, understanding the impact of cotton dyeing chemicals on Jiangsu textiles is crucial for ensuring that garments and fabrics maintain their original color and texture. Using the correct amount of textile dyestuffs and following proper application techniques can help minimize any adverse effects on the fabric's quality and longevity. By taking these steps, manufacturers can produce high-quality products that meet consumer expectations and stand out in the competitive market.

江苏纺织品匀染剂用量概述

江苏作为纺织业的重要省份,在纺织品生产过程中,匀染剂的使用量直接影响到产品质量和效率,本篇将详细介绍江苏纺织品匀染剂用量,并结合实际案例进行分析。

江苏纺织品匀染剂用量标准

- 纺织品类型与需求:不同类型和需求的纺织品需要使用不同剂量的匀染剂,棉织物通常需要较低的匀染剂用量,而丝绸织物则需要更高的匀染效果。

- 匀染剂用量影响因素:主要包括原料质量、染料类型、织物厚度、温度和湿度等,在生产实践中,需要根据具体情况调整匀染剂用量,以达到最佳的匀染效果。

实际案例分析

以某纺织企业为例,该企业采用江苏纺织品匀染剂进行纺织品生产,以下是该企业匀染剂用量的实际案例分析:

某品牌棉织物生产

原料:优质棉纤维

匀染剂用量:根据织物厚度和染料类型,该企业推荐使用适量的匀染剂,对于厚度较大的棉织物,推荐使用较低的匀染剂用量,以确保染色效果和织物性能。

提高丝绸织物匀染效果

原料:高品质丝绸纤维

为了提高丝绸织物的匀染效果,该企业采用了先进的匀染技术,并严格控制匀染剂用量,通过精确控制温度和湿度,以及合理搭配其他助剂,成功提高了丝绸织物的匀染效果。

表格补充说明

以下是江苏纺织品匀染剂用量表格的补充说明:

| 纺织品类型 | 用量标准 | 实际案例分析 | 注意事项 |

|---|---|---|---|

| 棉织物 | 根据织物厚度和染料类型确定 | 根据实际情况调整 | 确保染色效果和织物性能 |

| 丝绸织物 | 根据织物要求确定 | 采用先进的匀染技术,严格控制温度和湿度 | 注意控制匀染剂用量,避免过度染色或色泽不均匀 |

| 其他因素 | 其他助剂、环境因素等 | 根据实际情况综合考虑 | 注意综合考虑其他因素,确保匀染效果 |

江苏纺织品匀染剂用量需要根据纺织品类型和需求进行合理确定,在实际生产中,需要综合考虑原料质量、染料类型、织物厚度、温度和湿度等因素,以及采用先进的匀染技术,还需要注意控制匀染剂用量,避免过度染色或色泽不均匀等问题,通过合理的匀染剂用量,可以确保纺织品生产的质量和效率。

Articles related to the knowledge points of this article:

The New Wave of Textiles in Zhejiang:A Multitude of Opportunities