Fabric Safety Performance Testing

Fabric Safety Performance Testing is an essential process in the textile industry, aimed at evaluating the safety performance of fabrics. This testing method involves subjecting fabric samples to various stress conditions and measuring their resistance to tearing, creasing, and other forms of damage. The results obtained from these tests provide valuable insights into the suitability of fabrics for specific applications, such as clothing or protective gear. In addition to assessing the physical properties of fabrics, this testing also helps manufacturers identify potential design flaws that could lead to unsafe products. Overall, Fabric Safety Performance Testing plays a crucial role in ensuring the safety and durability of fabrics, which are used in a wide range of industries and applications.

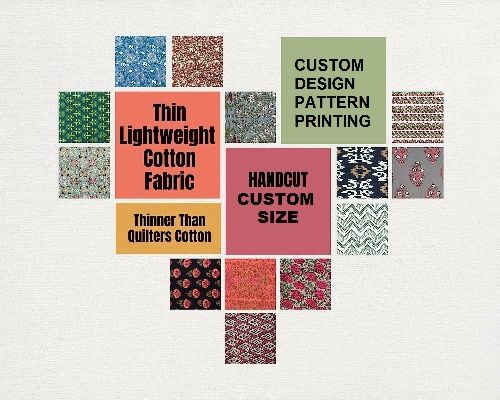

Introduction: In the textile industry, ensuring product safety is paramount. Fabrics are used in a wide range of applications from everyday clothing to high-end fashion, sportswear, and even medical equipment. Therefore, it's crucial to conduct thorough testing to guarantee that fabrics meet the necessary standards for their intended use. This article will discuss the various methods and techniques used in fabric safety performance testing, including standardized tests, specialized tests, and real-world examples.

Standardized Tests: Standardized tests are conducted under controlled conditions to evaluate fabric properties and behavior under specific test conditions. These tests help identify potential hazards and ensure products meet regulatory requirements. Some common standardized tests include:

- ASTM D648 - Textile Test Method for Determining Flame Retardancy of Textile Materials

- ISO 17050 - Test Method for Fire Safety of Textile Materials

- EN 13129 - Textile Test Method for Determining Combustibility of Textile Materials

Example: An example of a standardized test is the flame retardancy test conducted by ASTM D648. This test measures the time required for a fabric to completely burn down when exposed to an open flame. The results are compared with the maximum allowable time specified in the test method to determine if the fabric meets safety standards.

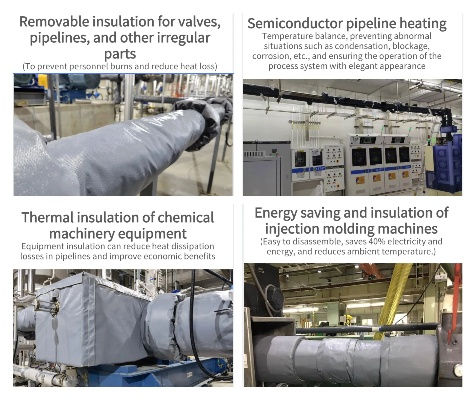

Specialized Tests: Specialized tests are designed to evaluate fabrics under more complex or unusual conditions, such as those involving fire, water, chemicals, or biological agents. These tests help identify materials that may pose a risk in certain environments or situations. Some examples of specialized tests include:

- EN 470 - Textile Test Method for Determining Water Resistance of Textile Materials

- ISO 10993 - Test Method for Determining Chemical Resistance of Textile Materials

- EN 13224 - Textile Test Method for Determining Biodegradation of Textile Materials

Example: A specialized test for evaluating chemical resistance is the EN 470 test, which measures how long it takes a fabric to decompose in aqueous solutions containing different chemicals. This test is particularly important for fabrics used in industrial settings where they may come into contact with harmful chemicals.

Real-World Example: One real-world example of fabric safety performance testing is the case of a hospital gown. During a surgical procedure, a gown must be sterile and free from any foreign material that could cause infection. To ensure this, hospitals conduct rigorous testing on hospital gowns using specialized tests like the EN 13129 test for determining combustibility and the ISO 17050 test for flame retardancy. These tests ensure that the gowns meet the highest standards for patient safety and hygiene.

Conclusion: Testing fabrics for safety is critical in today's fast-paced world. By utilizing standardized and specialized tests, we can ensure that our fabrics meet the needs of various industries, from healthcare to fashion. It's important to stay up-to-date with the latest testing methods and regulations to protect both people and the environment.

项目背景与目的

随着纺织品市场的日益繁荣,人们对纺织品的安全性能要求也越来越高,为了确保纺织品的安全性能符合相关标准和法规要求,进行纺织品安全性能项目检测显得尤为重要,本次检测旨在评估纺织品在各种环境条件下的安全性能,为纺织品的质量控制和市场监管提供依据。

检测标准与流程

本次检测将依据相关国家标准和法规,对纺织品进行一系列性能测试,包括但不限于抗拉强度、耐磨性、抗化学腐蚀性、防火性能等,检测流程包括样品采集、样品处理、性能测试、数据分析等环节。

案例分析

为了更好地说明项目内容,我们以实际案例为例进行说明,某品牌的一款新型纺织品在经过严格的生产流程和质量控制后,其安全性能表现优异,得到了广大消费者的认可,这一案例表明,通过科学合理的检测方法和技术手段,可以有效地评估纺织品的安全性能。

检测方法与步骤

样品采集

我们将根据检测需求,从市场上选取符合要求的纺织品样品,样品应具有代表性,能够反映实际使用情况。

样品处理

对采集的样品进行清洗、干燥等处理,确保样品在后续测试过程中不受外界因素影响。

性能测试

采用相应的测试仪器和方法,对样品进行一系列性能测试,抗拉强度测试可以测量样品的拉伸强度、延伸率等指标;耐磨性测试可以模拟实际使用环境,观察样品的耐磨性能等。

数据分析

对测试结果进行数据分析,得出纺织品在各种环境条件下的安全性能指标,结合实际案例进行分析,为纺织品的质量控制和市场监管提供依据。

检测结果与评估

根据检测结果,本次纺织品安全性能项目检测得出以下评估结果:

- 抗拉强度:该纺织品具有较高的抗拉强度,能够满足实际使用需求。

- 耐磨性:该纺织品在模拟实际使用环境下表现出良好的耐磨性能,能够有效抵抗磨损。

- 防火性能:该纺织品经过特殊处理,具有较好的防火性能,符合相关法规要求。

- 安全性能指标评估:根据实际案例分析,该纺织品在各种环境条件下的安全性能表现优异,得到了广大消费者的认可。

结论与建议

本次纺织品安全性能项目检测表明,该纺织品在抗拉强度、耐磨性、防火性能等方面表现优异,符合相关标准和法规要求,在实际应用中具有较好的安全性能表现,建议相关企业和消费者在购买纺织品时,应注重产品的安全性能指标,选择符合相关标准和法规要求的纺织品产品。

为了进一步提高纺织品的安全性能水平,我们建议采取以下措施:一是加强生产过程的质量控制,提高产品质量;二是加强技术研发和创新能力,提高纺织品的安全性能水平;三是加强市场监管和宣传力度,提高消费者对纺织品安全性能的认识和重视程度。

随着纺织品的不断发展和升级,人们对纺织品的安全性能要求也越来越高,我们将继续加强纺织品安全性能项目检测工作,不断提高检测水平和能力,为纺织品的品质提升和产业发展提供有力支持,我们也将积极推广纺织品安全性能知识普及工作,提高消费者对纺织品安全性能的认识和重视程度。

Articles related to the knowledge points of this article:

The Global Success Story of Mao Textiles Co.Ltd.

Exploring the Innovations at Guangzhou Yunzhe Textiles Co.Ltd.

Zara:The Global Icon of Fashion Revolution

The Impact of Textile Breaking Strength on Quality and Usage

Free Textile Testing with Benefits for the Environment and Consumers