The Design Process for Functional Textiles

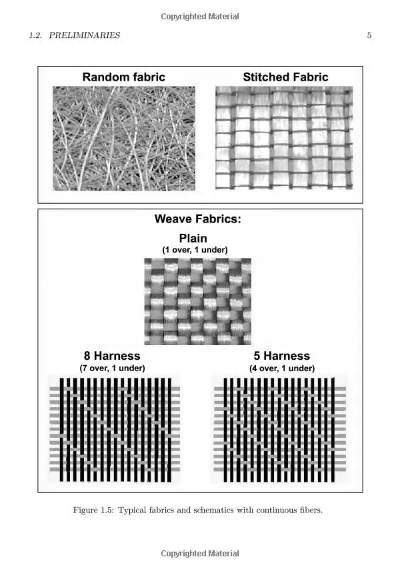

The design process for functional textiles involves a multidisciplinary approach that combines knowledge from various fields such as textile engineering, materials science, and human-computer interaction. The goal of the process is to create textiles that not only meet aesthetic and technical requirements but also have practical applications in daily life. The design process typically begins with a thorough analysis of the intended use and functionality of the textile, followed by a detailed study of the materials used in its production. This includes understanding the properties of the fibers, yarns, and fabrics, as well as their potential applications in different environments. Once the material selection is complete, the next step is to develop a prototype or mockup of the textile based on the design concept. This prototype is then tested and evaluated for its performance in various conditions, including wear and tear, temperature changes, and exposure to moisture and chemicals. Based on the results of these tests, further modifications can be made to the design until it meets all the required specifications. Finally, once the functional textile has been designed and tested successfully, it is ready to be produced in large quantities for commercial distribution.

Introduction Textiles have been an integral part of human life since the dawn of civilization. From ancient loom-weaving to modern high-tech materials, textiles have evolved with the times, becoming more functional, durable, and sustainable. In this article, we will discuss the design process for functional textiles, including the steps involved in creating innovative textile products that meet the needs of different users. We will also highlight some successful examples of functional textile design.

Step 1: Conceptualization The first step in the design process is conceptualization. This involves brainstorming ideas, researching existing products, and identifying market trends. It's important to understand the target audience and their needs before developing a product. For example, if you are designing a clothing item, you need to consider factors such as comfort, style, and functionality. You can use a table to summarize your ideas and prioritize them based on importance.

Step 2: Research and Analysis Once you have a clear idea of the product, it's time to conduct thorough research and analysis. This includes gathering information about the target market, competitors, and materials available. You can use online databases, industry reports, and interviews to gather data. This stage is crucial as it helps you identify gaps in the market and develop a unique selling proposition (USP).

Step 3: Design Development The next step is designing the product. This involves creating sketches, CAD models, and prototypes. You can use software like SketchUp or AutoCAD to create detailed designs. It's essential to test your designs thoroughly during this stage to ensure they meet the required specifications.

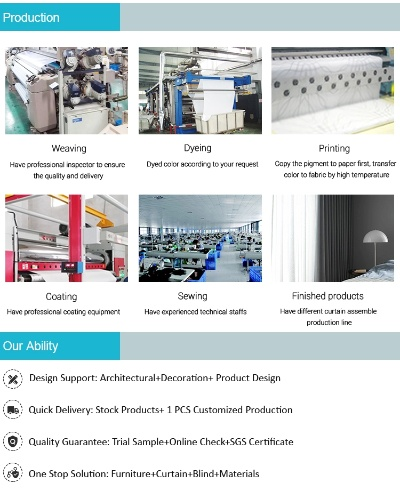

Step 4: Production Planning After developing the design, you need to plan the production process. This includes selecting the right manufacturing techniques, sourcing materials, and determining the production schedule. You can use a table to track the progress of each step and ensure that everything is on track.

Step 5: Quality Control Quality control is critical in the production process. You need to inspect your products for defects and ensure they meet the required standards. This can be done using various tools and techniques, such as visual inspection, testing, and certification.

Step 6: Packaging and Shipping Packaging and shipping are essential in ensuring that your product reaches its intended destination safely and efficiently. You need to choose the right packaging materials and design effective shipping labels. You can use a table to track the progress of each step and ensure that everything is on track.

Successful Example: Smart Underwear One successful example of functional textile design is smart underwear. A company called "SmartUnder" has developed a line of wearable technology that monitors heart rate, blood oxygen levels, and sleep patterns. The underwear is made from a fabric that reacts to body heat, providing comfort and support while also tracking vital signs. The company uses a table to track the progress of each step in the design process, from conceptualization to production planning. They also use a variety of techniques to ensure that the product meets all necessary standards.

Conclusion In conclusion, the design process for functional textiles involves several steps, from conceptualization to production planning. By following a structured approach, you can create innovative textile products that meet the needs of different users. Remember to conduct thorough research and analysis, design development, quality control, packaging and shipping, and use a table to track the progress of each step. With dedication and creativity, you can create functional textiles that inspire and transform our lives.

功能纺织品作为现代纺织工业的重要组成部分,其设计流程对于提升产品性能、满足市场需求具有重要意义,本文将详细介绍功能纺织品设计流程,并通过英文案例说明来进一步阐述。

功能纺织品设计流程概述

市场调研与分析

在开始设计之前,首先进行市场调研与分析,了解目标客户的需求、市场趋势以及竞争对手的情况。

设计概念确定

根据市场调研结果,确定功能纺织品的创新设计理念和功能特点。

材料选择与评估

选择适合材料进行纺织加工,并对材料的性能、环保性、耐用性等进行评估。

结构设计与优化

根据设计理念和功能特点,进行结构设计,优化产品性能,同时考虑产品的舒适性、耐用性、安全性等因素。

功能性测试与验证

对产品设计进行功能性测试,确保其符合相关标准和法规要求,同时收集用户反馈,进行验证和改进。

英文案例说明

以某品牌的功能纺织品设计为例,详细说明其设计流程。

市场调研与分析

该品牌关注功能性纺织品市场的需求变化,了解目标客户对产品性能、舒适性、环保性等方面的要求,通过市场调研发现,市场上对具有良好透气性、吸湿性、防紫外线等功能的纺织品需求较大。

设计概念确定

基于市场调研结果,该品牌确定以“舒适透气、环保可持续”为设计理念,推出具有抗菌、防臭、防过敏等功能性的纺织品。

材料选择与评估

选择具有良好透气性和吸湿性的天然纤维作为主要材料,同时考虑环保性,选用可降解的材料,对所选材料进行性能评估,确保其符合相关标准和法规要求。

结构设计与优化

根据设计理念和功能特点,进行结构设计,该品牌注重产品的舒适性和耐用性,采用先进的织造技术,优化产品结构,同时考虑产品的安全性,添加了防漏设计,经过多次优化和改进,最终形成了具有良好透气性、吸湿性、抗菌防臭功能的纺织品。

功能测试与验证

对该品牌推出的功能纺织品进行功能性测试,确保其符合相关标准和法规要求,测试结果表明,该产品具有良好的透气性、吸湿性、抗菌防臭性能,同时符合环保要求,用户反馈也表明该产品深受市场欢迎。

功能纺织品设计流程补充说明(表格形式)

以下是功能纺织品设计流程补充说明的表格形式:

| 步骤 | 描述 | 示例说明 | |

|---|---|---|---|

| 市场调研与分析 | 了解市场需求、市场趋势和竞争对手情况 | 进行市场调研分析,收集用户需求和反馈 | 该品牌进行了全面的市场调研,了解了目标客户的需求和市场的变化趋势 |

| 设计概念确定 | 确定创新设计理念和功能特点 | 根据市场需求和竞争对手情况确定设计理念和功能特点 | 该品牌确定了以舒适透气、环保可持续为设计理念,并强调抗菌防臭等功能性特点 |

| 材料选择与评估 | 选择适合材料进行纺织加工 | 对材料进行性能评估,确保其符合相关标准和法规要求 | 该品牌选择了具有良好透气性和吸湿性的天然纤维作为主要材料 |

| 结构设计优化 | 进行结构设计优化 | 根据设计理念和功能特点进行结构设计优化 | 该品牌注重产品的舒适性和耐用性,采用了先进的织造技术优化产品结构 |

| 功能测试与验证 | 进行功能性测试与验证 | 对产品设计进行功能性测试和验证,确保其符合相关标准和法规要求 | 该品牌进行了多轮的测试和验证工作,确保产品性能符合相关标准和法规要求 |

| 案例总结与启示 | 总结设计流程与案例启示 | 通过案例总结与设计流程的启示 | 通过该品牌的案例可以看出,功能纺织品设计流程需要综合考虑市场需求、材料选择、结构设计以及功能性测试等多个方面的工作 |

功能纺织品设计流程是一个复杂而严谨的过程,需要综合考虑市场需求、材料选择、结构设计以及功能性测试等多个方面的工作,通过上述英文案例说明和补充说明内容,可以更好地了解功能纺织品设计流程的相关知识,在实际设计中,还需要根据具体情况进行灵活运用和调整。

Articles related to the knowledge points of this article:

Exploring the Rich Traditions of Rui Tao Textiles in Shaoxing

Mastering Photoshop for Editing Textiles A Comprehensive Guide

Strategies for Degrading Formaldehyde in Textile Products

The Fabric of Success:Navigating the World of Nantong Anton Textiles

Technological Advancements:The Backbone of Digital Transformation