The Role of Tensile Strength in Textiles:A Comprehensive Guide

Tensile strength is a crucial property of textiles, playing a vital role in determining their durability and performance. This comprehensive guide will explore the various aspects of tensile strength in textiles, including its definition, measurement methods, and applications in different industries.,Tensile strength refers to the maximum force that can be applied to a material without causing it to break or deform. In textiles, this property is essential for understanding how strong materials are and how they can withstand wear and tear.,There are several ways to measure tensile strength in textiles, including using a tensile tester or a grip tester. These devices apply a constant force to the material and measure the resulting deformation or breaking point.,Tensile strength is important for many industries, including apparel, sportswear, and industrial fabrics. In apparel, it helps determine how durable and comfortable clothes are, while in sportswear, it determines how well the material can withstand impacts and friction. In industrial fabrics, it helps determine how well the material can withstand wear and tear, which is critical for machinery parts and other heavy-duty applications.,In conclusion, tensile strength is a crucial property of textiles that plays a vital role in determining their durability and performance. By understanding this property, manufacturers and designers can make more informed decisions about the materials they use and the products they produce.

Introduction to Tensile Strength in Textiles: Tensile strength, also known as breaking strength or tensile modulus, is a crucial property in textiles that describes the maximum force at which a material can resist being stretched. This measure is essential for understanding how durable and resilient materials are against mechanical stresses such as tension, compression, and bending. In this guide, we will explore the role of tensile strength in textiles, including its importance, measurement methods, applications, and case studies.

Importance of Tensile Strength in Textiles:

- Durability: High tensile strength textiles are more resistant to wear and tear, making them ideal for outdoor activities like sportswear, military uniforms, and industrial equipment.

- Reliability: When subjected to repeated stretching, materials with high tensile strength exhibit less deformation, ensuring long-term performance and reliability.

- Environmental Resilience: Strong textiles are better able to withstand harsh environmental conditions, such as high temperatures, moisture, and chemicals, contributing to their durability in various settings.

- Safety: Industries that require high levels of safety, such as construction, mining, and manufacturing, rely on textiles with high tensile strength to prevent accidents caused by sudden stretching.

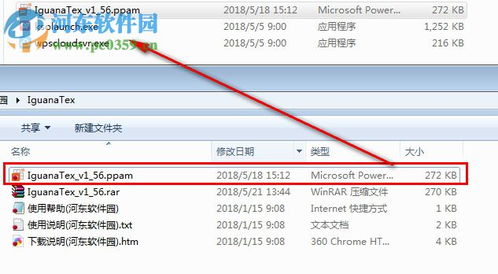

Measuring Tensile Strength: There are several methods used to measure tensile strength in textiles:

- Tensile Testing: This involves subjecting fabric samples to a controlled extension until they break. The maximum force required to cause the fabric to break is recorded as the tensile strength.

- Tensile Strength Index (TSI): A ratio calculated by dividing the tensile strength by the elongation at break. This provides an indication of the material's ability to stretch without breaking.

- Yield Point Test: This method measures the point at which a sample begins to yield before it breaks. It provides insight into the material's elasticity and resilience.

- Elongation Test: This test measures the amount of elongation (lengthening) a textile sample can sustain before failure. High elongation means greater flexibility but may not necessarily indicate high tensile strength.

Applications of Tensile Strength in Textiles:

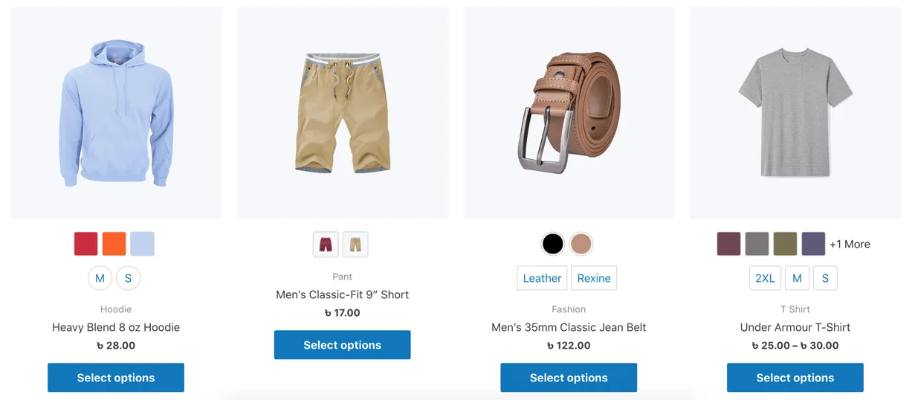

- Sportswear: High-performance sportswear made from materials with high tensile strength ensures comfort and support during intense activities.

- Military Equipment: Materials with high tensile strength are crucial for armor protection and gear durability in extreme environments.

- Industrial Wear: Industries that require tough, durable textiles for heavy-duty machinery, conveyor belts, and other equipment use materials with high tensile strength.

- Medical Supplies: Medical textiles need to be highly resistant to bacterial growth and infection, making materials with high tensile strength ideal for surgical gowns, masks, and wound dressings.

Case Studies:

- Britain's Armed Forces: The UK's armed forces have relied on high-strength textiles for decades. For example, the British Army's combat fatigues are made from specially formulated polyester fibers that provide excellent resistance to abrasion and tearing, thanks to their high tensile strength. These garments are designed to withstand the rigors of battlefield conditions, ensuring soldiers' comfort and safety.

- The American Navy: The U.S. Navy has extensively utilized high-strength textiles in its ships' sails, lifeboats, and emergency response gear. The Navy's choice of materials, such as Kevlar and carbon fiber composites, reflects their commitment to superior durability and performance in harsh environments.

- Medical Devices: Medical devices that require high levels of sterility and strength, such as surgical instruments, catheters, and implants, often use materials with high tensile strength to ensure longevity and efficacy. For instance, medical implants made from titanium alloys have been shown to provide superior resistance to corrosion and wear compared to traditional metals.

Conclusion: Tensile strength is a critical factor in determining the quality and performance of textiles. By understanding its importance and measuring its properties, industries can select materials that meet their specific needs for durability, reliability, and safety. Case studies demonstrate the wide range of applications where high-strength textiles are essential, highlighting their impact on the performance and success of various sectors. As technology continues to advance, so too does our understanding of how to harness the full potential of textiles through innovative materials and designs that prioritize tensile strength.

抗拉强度纺织品概述

抗拉强度纺织品是一种高性能的纺织品,用于承受高强度拉力的场合,它们通常由高强度纤维、特殊织造工艺和高质量的原材料制成,抗拉强度纺织品在各种领域都有广泛的应用,包括户外装备、运动服装、家居装饰等。

抗拉强度纤维类型

- 聚酯纤维(Polyester):聚酯纤维是一种常用的抗拉强度纤维,具有高强度和高弹性,它具有优良的耐磨性、抗皱性和抗撕裂性,能够承受较大的拉力。

- 氨纶纤维(Spandex):氨纶纤维是一种弹性纤维,具有高拉伸性和高抗拉强度,它广泛应用于运动服装和功能性纺织品中,能够提供出色的弹性恢复性能。

抗拉强度纺织品的特点

- 高强度:抗拉强度纺织品能够承受高强度的拉力,适用于各种恶劣环境。

- 耐用性:经过特殊处理和制造工艺,抗拉强度纺织品具有较长的使用寿命。

- 舒适性:采用柔软、舒适的织造工艺,抗拉强度纺织品适合各种穿着场合。

案例分析

户外装备中的抗拉强度纺织品

近年来,户外装备市场对抗拉强度纺织品的需求日益增长,登山鞋、帐篷等户外装备中使用的抗拉强度纺织品,需要具备高强度、耐磨、耐久性等特点,某品牌的一款登山鞋采用特殊聚酯纤维和氨纶纤维混纺面料,经过特殊处理和制造工艺,具有出色的抗拉强度和耐用性,深受消费者喜爱。

运动服装中的抗拉强度纺织品

运动服装是抗拉强度纺织品的重要应用领域之一,在运动服装中,抗拉强度纤维的应用可以提高服装的舒适性和耐用性,某品牌的一款运动裤采用高强度聚酯纤维和氨纶纤维混纺面料,具有出色的弹性和舒适度,适合各种运动场景,该品牌还注重环保和可持续性,采用可回收材料制作面料,符合现代消费者的环保需求。

提高抗拉强度的方法

- 选择高质量的原材料:选择高质量的原材料是提高抗拉强度的基础,只有使用高质量的原材料制成的纺织品,才能满足高强度和耐用性的要求。

- 优化织造工艺:优化织造工艺可以提高纺织品的抗拉强度和耐用性,采用特殊的织造工艺可以增加织物的厚度和密度,提高其抗拉强度。

- 添加增强纤维:在纺织过程中添加增强纤维可以提高纺织品的抗拉强度,可以添加碳纤维、玻璃纤维等高性能纤维,提高纺织品的耐久性和强度。

抗拉强度纺织品是一种高性能的纺织品,具有高强度、耐用性、舒适性和环保等特点,在各种领域中都有广泛的应用,包括户外装备、运动服装、家居装饰等,通过选择高质量的原材料、优化织造工艺和添加增强纤维等方法,可以提高抗拉强度纺织品的性能和质量,随着科技的不断进步,抗拉强度纺织品的制造工艺和技术也在不断更新和发展,为人们提供了更多的选择和可能性。

Articles related to the knowledge points of this article:

The Impact of Textile Tariffs on Global Trade and Employment

Exploring the World of Japanese Textile Finishes and Additives

High Yang Famous Textile Brands:A Review of Specialty Stores