The Art of Textile Belts Production:A Comprehensive Guide

"The Art of Textile Belts Production: A Comprehensive Guide" is a comprehensive guide to the art of textile belt production. It covers everything from the basic principles of textile belt production, such as the importance of quality control and precision manufacturing, to more advanced techniques and processes.,The book provides detailed instructions on how to select the right materials for textile belt production, including the selection of high-quality raw materials and the use of specialized machinery. It also covers the various steps involved in the production process, from cutting and weaving to finishing and packaging.,In addition to technical information, the book also includes practical tips and tricks for successful textile belt production, such as how to optimize production efficiency and reduce waste. It also covers common issues that can arise during the production process, such as molding problems and quality control issues.,Overall, "The Art of Textile Belts Production: A Comprehensive Guide" is an essential resource for anyone involved in textile belt production, providing a comprehensive overview of the industry's best practices and techniques.

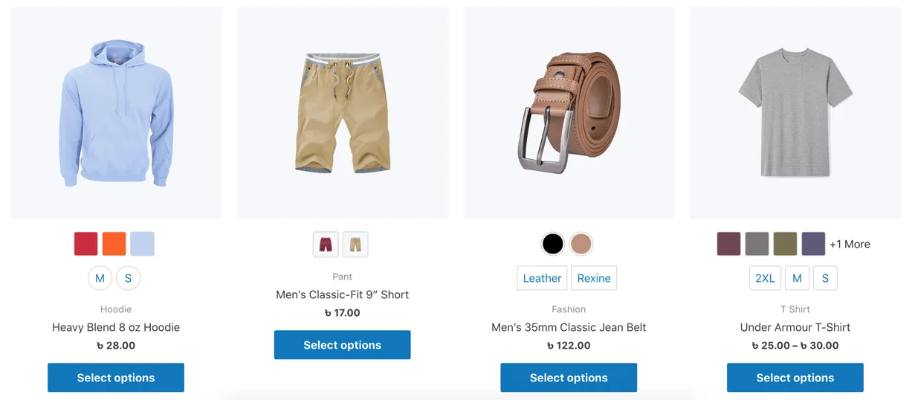

Introduction: Textile belts, often referred to as "belts" in the industry, are a crucial component in a wide range of applications from automotive to industrial machinery. From securing components to providing cushioning, they play a vital role in maintaining efficiency and reducing downtime. In this guide, we'll explore the production process, highlight the key steps involved, and provide insights into the latest trends in textile belt technology.

Table 1: Textile Belt Production Process | Step | Description | |------|--------------| | Material Selection | Identifying high-quality raw materials for the production of textile belts. | | Preparation | Properly preparing the raw materials for processing. | | Weaving | Creating the fabric structure using a loom or other weaving technique. | | Dyeing | Applying dyes to the fabric to achieve the desired color pattern. | | Stitching | Joining the fabric edges together using a sewing machine or manual stitching. | | Cutting | Slicing the fabric into individual belt segments. | | Finishing | Applying finishing treatments like coatings or abrasives to enhance durability and appearance. | | Quality Control | Checking the finished product for defects and ensuring it meets quality standards. |

Case Study: One of the most renowned textile belt producers is the American company, "Beltec International." Beltec specializes in producing high-performance automotive belts, including those used in transmission systems. Here's how their production process works:

- Material Selection: Beltec selects premium polyester fibers for its belts due to their strength and resistance to wear and tear.

- Preparation: The raw materials undergo thorough cleaning and conditioning to ensure uniformity and consistency.

- Weaving: Beltec uses advanced digital loom technology to create its unique woven patterns, ensuring precision and repeatability.

- Dyeing: The fabric is dyed with eco-friendly dyes to meet strict environmental standards.

- Stitching: Beltec employs state-of-the-art automated sewing machines that ensure consistent stitching and fast turnaround times.

- Cutting: The fabric is precisely cut into precise lengths using computer-controlled cutting equipment.

- Finishing: After cutting, each belt is subjected to additional finishing treatments like flame polishing to enhance its appearance and durability.

- Quality Control: Beltec rigorously checks every belt for quality issues during the manufacturing process, ensuring only high-quality products reach the customer.

- Packaging: Finally, the belts are packaged securely to protect them during transportation and storage.

Conclusion: Textile belt production is a complex yet rewarding process that involves meticulous planning, advanced technology, and stringent quality control. By following the steps outlined in this guide, businesses can produce high-quality textile belts that meet the demands of various industries. As technology continues to evolve, so too does the production process, making it essential for companies to stay updated on the latest advancements in textile belt technology. Whether you're a small manufacturer or a large corporation, understanding the textile belt production process can help you stay ahead of the competition and deliver exceptional products to your customers.

大家好,今天我们将围绕纺织品布带生产这一主题展开讨论,随着纺织行业的不断发展,纺织品布带作为重要的生产材料,其生产过程和技术水平也在不断提高,下面我们将通过一个英文案例说明和表格补充说明的方式,为大家详细介绍纺织品布带生产的相关知识。

纺织品布带生产概述

纺织品布带是一种广泛应用于各种行业的产品,包括服装、家居装饰、户外用品等,其生产过程主要包括原料准备、织造、染整和成品检验等环节,在生产过程中,需要使用各种纺织材料和工艺技术,以确保产品的质量和性能。

案例说明

原料准备

在纺织品布带生产中,原料的选择至关重要,需要选择高质量的纤维材料,以确保布带具有优良的弹性和耐磨性,需要根据产品的设计要求和性能指标,选择合适的织造工艺和技术,还需要对原料进行预处理,如清洗、梳理等。

织造工艺

织造工艺是纺织品布带生产的关键环节,常见的织造工艺包括平纹织造、斜纹织造、提花织造等,不同的织造工艺适用于不同的产品需求和材料特性,平纹织造适用于轻薄、柔软的产品,而提花织造则适用于具有复杂图案的产品,还需要根据产品的尺寸和形状,选择合适的织机和技术参数。

染整工艺

染整工艺是纺织品布带生产中的重要环节之一,染整工艺包括染色、印花、整理等步骤,在染色过程中,需要使用合适的染料和染色技术,以确保产品的颜色和质量,印花过程中,需要使用特殊的印花技术,以实现产品的图案设计,整理过程中,还需要对布带进行柔软度、耐磨性等方面的处理。

表格补充说明

以下是纺织品布带生产过程中的一些关键参数和指标的表格补充说明:

表格1:纺织品布带生产参数和指标

| 参数/指标 | 描述 |

|---|---|

| 原料选择 | 选择高质量的纤维材料,确保产品具有优良的弹性和耐磨性 |

| 织造工艺 | 平纹织造、斜纹织造、提花织等 |

| 设备参数 | 织机型号、技术参数等 |

| 染整工艺 | 染色工艺参数、印花工艺参数等 |

| 产品性能指标 | 弹性、耐磨性、颜色、柔软度等 |

纺织品布带生产发展趋势

随着科技的不断进步和人们对于产品品质的要求不断提高,纺织品布带生产也在不断发展,纺织品布带生产将更加注重环保、节能和智能化等方面的发展,纺织品布带的生产过程也将更加注重质量控制和安全生产,以确保产品的质量和安全性。

纺织品布带生产是一项重要的工业生产活动,其生产过程和技术水平对于产品的质量和性能有着至关重要的影响,在纺织品布带生产过程中,需要注重原料选择、织造工艺、染整工艺等方面的控制,以确保产品的质量和性能达到要求,随着科技的不断进步和人们对于产品品质的要求不断提高,纺织品布带生产也将面临更多的机遇和挑战。

Articles related to the knowledge points of this article:

The Unmatched Luxurious Experience with JinShang Textiles

The Latest Trend in Textile Brands:Top 10 Global Brands in Textiles