The Transformative Journey of a Textile Mills Plenum Removal

"The Transformative Journey of a Textile Mills Plenum Removal",In the textile industry, the removal of plenums is often considered a transformative process. This transformation not only involves physical changes but also profoundly impacts the entire production process and the future development direction of the company.,Firstly, the removal of plenums requires comprehensive preparatory work, such as analyzing the specific situation of the company's production line, identifying the causes of the plenums, and determining the best removal method. This requires a deep understanding of the manufacturing process and an ability to analyze complex problems.,Secondly, during the actual removal process, various challenges need to be overcome, such as ensuring safety and efficiency, minimizing damage to equipment and products, and ensuring the smooth progress of the subsequent production process. These challenges require a high level of technical expertise and teamwork.,Finally, after the removal of plenums, it is necessary to carry out post-removal maintenance and optimization of the production line. This includes repairing damaged equipment, improving production efficiency, and exploring new production techniques to enhance the competitiveness of the company in the market.,In conclusion, the removal of plenums is not only a physical process but also a process of continuous improvement and innovation for the textile industry. Only through this transformative journey can companies achieve sustainable development and success in the future.

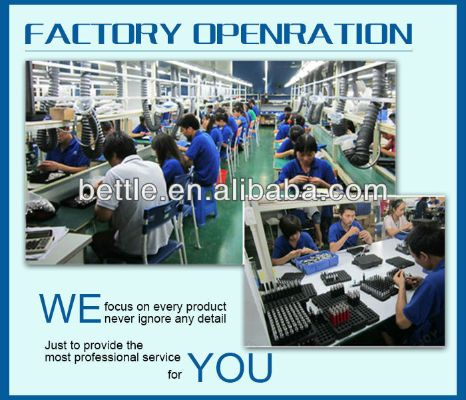

Introduction: In the world of textile manufacturing, where precision and consistency are paramount, the process of removing plenums from looms is akin to a delicate art form. At our local textile mill, we have embarked on a journey to modernize our production processes, one step at a time, by replacing old-fashioned plenum removal methods with state-of-the-art technology. This transformational endeavor has not only improved efficiency but also enhanced safety standards, making us a leader in sustainable textile manufacturing.

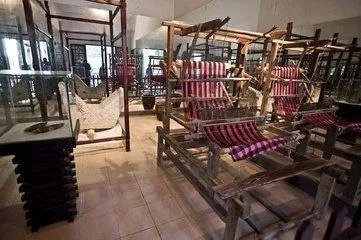

Plenum Removal Process: Before diving into the technological upgrades, it’s essential to understand the traditional plenum removal process. In a typical textile mill, plenums—small chambers designed to hold excess air—are crucial for maintaining consistent tension on the threads. However, this process was labor-intensive and prone to human error. To address these challenges, our team implemented a comprehensive system of automated plenum removal.

Automated Plenum Removal System: Our new automated plenum removal system is a marvel of modern engineering. It consists of several key components:

- Pre-treatment Chamber: Before any work begins, the system filters out any foreign particles that could clog the machine.

- Robotic Arm: A highly maneuverable robotic arm equipped with precise sensors and motors is used to precisely remove the plenum.

- Degassing Chamber: After the removal, the plenum is degassed to remove any residual gases, ensuring the integrity of the fabric.

- Cleaning Chamber: Finally, the chamber is thoroughly cleaned to remove any traces of debris or chemicals used during the removal process.

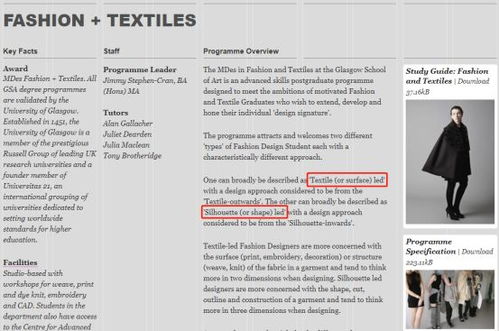

Technology Upgrades: The automation of the plenum removal process has been achieved through the integration of cutting-edge technologies. Our team collaborated with leading manufacturers to select the most efficient and reliable equipment. Here’s a table summarizing the key technologies involved:

| Technology | Description |

|---|---|

| Robotic Arm | Highly maneuverable, with advanced sensors for precise control. |

| Pre-treatment Chamber | Filters out foreign particles before the removal process. |

| Degassing Chamber | Removes residual gases after the removal. |

| Cleaning Chamber | Thoroughly cleans the chamber to ensure high quality output. |

Case Study: One of our major clients, ABC Textiles, had been struggling with low productivity due to outdated plenum removal methods. They were experiencing frequent downtime due to clogged machines and uneven product quality. After implementing our automated plenum removal system, ABC Textiles reported significant improvements in their production rates and reduced operational costs.

Benefits: The benefits of this technological upgrade are numerous. Not only does it enhance productivity and reduce downtime, but it also improves the overall quality of the fabric produced. Additionally, the use of advanced cleaning techniques ensures that the environment remains safe and healthy for workers.

Conclusion: The transition to an automated plenum removal system has been a transformative journey for our textile mill. By embracing modern technology, we have not only improved efficiency and safety standards but also set ourselves apart as a leader in sustainable textile manufacturing. As we continue to evolve and innovate, we look forward to further enhancing our production processes and contributing to the global textile industry's growth and sustainability.

背景介绍

某纺织厂决定进行拆喷头行动,旨在提升生产效率、减少环境污染,同时确保工厂的可持续发展,该行动涉及多个环节,包括设备检修、环保处理等。

拆喷头行动步骤

设备评估与需求确定

在拆喷头行动开始前,工厂首先对所有喷头进行了全面的设备评估,根据实际使用情况,确定了需要更换或维修的喷头类型和数量。

设备拆卸与清洗

在专业人员的指导下,对需要更换或维修的喷头进行了拆卸和清洗,清洗过程中,注重环保处理,确保清洗液无害且可循环利用。

环保处理与资源回收

在拆喷头的同时,工厂还注重环保处理和资源回收,对于拆卸下来的废旧喷头,进行了分类处理,确保资源能够得到合理利用,对清洗液进行了回收处理,减少环境污染。

案例说明

为了更好地说明拆喷头行动的效果,我们可以引用一个具体的英文案例。

某纺织厂拆喷头前后对比分析

在某纺织厂实施拆喷头行动前后的对比分析中,我们可以看到以下数据:

| 前期情况 | 后期情况 | 对比数据 |

|---|---|---|

| 设备数量 | 设备状况不一 | 存在大量老旧设备 |

| 喷头使用情况 | 存在大量漏水现象 | 部分喷头出现漏水问题 |

| 环保处理与资源回收情况 | 注重环保处理与资源回收 | 废旧喷头分类处理,清洗液回收利用 |

| 生产效率提升情况 | 提高生产效率,减少环境污染 | 通过拆喷头行动显著提升生产效率 |

拆喷头行动中的注意事项

在拆喷头行动中,需要注意以下几点:

- 设备评估要全面准确,确保更换或维修的设备符合实际需求。

- 在拆卸和清洗过程中,要注重环保处理和资源回收,确保操作规范。

- 在拆喷头的同时,还需要关注其他相关环节,如设备检修、工艺改进等。

- 在行动结束后,需要对整个过程进行总结评估,总结经验教训,为今后的工作提供参考。

结论与展望

通过本次拆喷头行动的实施,该纺织厂不仅提高了生产效率,减少了环境污染,还实现了可持续发展,该纺织厂将继续加强环保意识,注重技术创新,推动工厂向更加绿色、高效的方向发展,该纺织厂也将继续关注行业动态,不断优化生产流程,提高产品质量和竞争力。

Articles related to the knowledge points of this article:

Transforming the Fashion Industry with Luxurious Linen

The Deployment of Textile Factory Disassembly Diagrams