Comprehensive Guide to Fire Prevention Measures in the Textile Industry

: Comprehensive Guide to Fire Prevention Measures in the Textile Industry,Introduction:,The textile industry, characterized by its high energy consumption and extensive use of flammable materials, poses a significant risk of fire accidents. This comprehensive guide aims to provide a thorough overview of fire prevention measures essential for the textile industry.,Fire Hazards in the Textile Industry:,The textile industry is subject to various fire hazards, including electrical short circuits, overheating, and ignition of flammable materials. Proper management of these hazards can significantly reduce the risk of fire incidents.,Fire Prevention Measures in the Textile Industry:,1. Fire Safety Training: All employees should receive regular fire safety training to enhance their awareness and ability to respond to emergency situations.,2. Fire Extinguishers: Provision of fire extinguishers and appropriate storage facilities is essential to ensure quick response during a fire outbreak.,3. Electrical Safety: Ensure that all electrical equipment is regularly inspected and maintained to prevent electrical short circuits and overheating.,4. Flammable Materials Management: Implement strict regulations on the storage and handling of flammable materials to minimize the risk of ignition.,5. Ventilation System: Install efficient ventilation systems to remove harmful gases and prevent fire spread.,6. Building Construction: Ensure that all buildings comply with fire safety standards and have proper fire escape routes.,7. Emergency Plan: Develop an effective emergency plan that outlines procedures for responding to fire emergencies and ensuring the safe evacuation of personnel.,8. Regular Audits: Conduct regular audits to identify potential fire hazards and address them promptly.,9. Infrastructure Protection: Ensure that all infrastructure, such as power lines and cables, are properly protected to prevent ignition.,10. Environmental Control: Maintain a clean and dust-free work environment to reduce the risk of fires caused by accumulation of flammable particles.,Conclusion:,In conclusion, implementing comprehensive fire prevention measures in the textile industry is crucial for ensuring worker safety and protecting property. By following this guide, organizations can effectively mitigate fire risks and develop robust emergency preparedness plans.

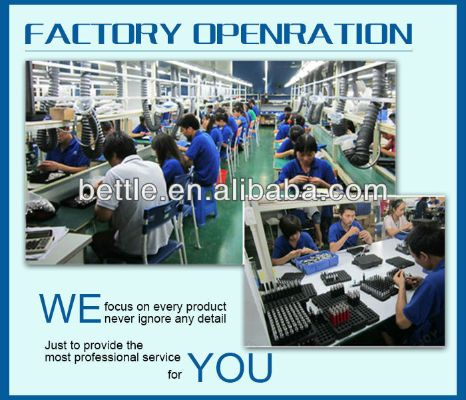

Introduction: The textile industry is a crucial sector that employs millions of people worldwide. However, it also poses significant fire hazards due to the high levels of combustible materials used in production processes. In this guide, we will discuss the essential fire prevention measures that must be followed to ensure the safety of workers and property.

Fire Safety Regulations: Every textile factory must comply with stringent fire safety regulations to prevent accidents and minimize the risk of fire outbreaks. Some of the key regulations include:

-

Fire Extinguishers: All workplaces should have adequate fire extinguishers at hand and trained personnel who can use them effectively. The type of extinguisher required depends on the level of combustibility of the material being processed.

-

Ventilation Systems: Proper ventilation systems are essential to prevent the buildup of smoke and toxic gases that can cause respiratory problems or even death.

-

Fire Alarm Systems: High-quality fire alarm systems should be installed throughout the factory to alert employees and authorities of any potential fire hazards.

-

Fire Safety Training: Regular fire safety training should be provided to all employees to ensure they understand the importance of following fire safety procedures.

-

Workplace Rules: Clear rules and regulations should be established for working hours, equipment usage, and other factors that could lead to fire incidents.

-

Emergency Plans: A comprehensive emergency plan should be developed to guide employees in case of a fire emergency. This plan should include evacuation routes, communication protocols, and first aid instructions.

Table: Fire Safety Regulations for Textile Factories | Regulation | Description | |------------|-------------| | Fire Extinguishers | Available at all workstations | | Ventilation Systems | Ensure adequate airflow to prevent smoke accumulation | | Fire Alarm Systems | Installed to detect and respond to fire emergencies | | Fire Safety Training | Conduct regular training sessions for all employees | | Workplace Rules | Establish clear guidelines for working hours and equipment usage | | Emergency Plans | Develop an effective plan for handling fire emergencies |

Fire Safety Practices: In addition to the regulations mentioned above, there are several practices that can help prevent fires in the textile industry. These include:

-

Proper Handling of Flammable Materials: Flammable materials such as solvents and chemicals should be handled carefully to avoid spills and leaks.

-

Use of Non-Combustible Materials: Non-combustible materials like plastic bags, foam, and metal containers should be used instead of flammable ones.

-

Avoiding Overcrowding: Ensure there is enough space between workstations to prevent fires from spreading rapidly.

-

Using Proper Tools: Only use approved tools and equipment that are designed for their intended purpose.

-

Proper Waste Management: All waste should be disposed of properly to prevent fire hazards from accumulating.

-

Regular Maintenance of Machinery: Regular maintenance of machinery ensures that it operates safely and does not contribute to fire risks.

Case Study: A textile company in China experienced a major fire outbreak in its manufacturing plant. The fire was caused by a faulty electrical circuit that led to a short circuit in one of the machines. The company had implemented strict fire safety regulations, including regular training for its employees, but the incident highlighted the need for more thorough inspections and maintenance of machinery.

Conclusion: In conclusion, implementing fire safety measures is critical for the success of the textile industry. By following the guidelines outlined in this guide, companies can reduce the risk of fire incidents and protect their workers and assets. It is essential to remember that fire prevention is not just a matter of compliance; it is a responsibility that requires ongoing attention and investment.

纺织厂防火规定概述

纺织厂作为生产各类纺织品的重要场所,其防火工作至关重要,为了确保员工和财产安全,纺织厂必须制定并执行严格的防火规定,本篇文章将详细介绍纺织厂防火规定的主要内容,并结合案例说明,帮助大家更好地理解和遵守。

纺织厂防火规定要点

消防设施配置

纺织厂应确保有完善的消防设施,包括但不限于灭火器、消防栓、烟雾探测器等,这些设施应定期检查和维护,确保其有效性。

禁止吸烟和明火作业

纺织厂内严禁吸烟和进行明火作业,所有易燃物品应存放在指定区域,并确保无任何火源。

员工培训与意识提升

纺织厂应定期对员工进行防火安全培训,提高员工的防火意识和技能,在厂区内设置防火宣传栏,提醒员工注意防火安全。

消防演练与应急预案

纺织厂应定期进行消防演练,确保员工熟悉应急预案,知道如何正确应对火灾等突发情况。

案例分析

某纺织厂防火规定执行情况

某纺织厂在防火规定执行方面做得较好,该厂配备了完善的消防设施,禁止吸烟和明火作业,定期对员工进行防火安全培训,并制定了详细的应急预案,该厂还设有专门的防火宣传栏,提醒员工注意防火安全,在消防演练方面,该厂也做得非常出色,员工能够熟练掌握应对火灾等突发情况的方法。

防火意识不足的纺织厂案例

有些纺织厂在防火规定执行方面存在不足,这些厂可能没有完善的消防设施,或者没有定期进行员工培训,一些厂区的防火宣传栏可能缺乏更新或内容不准确,这些情况都可能导致火灾事故的发生。

防火措施与建议

为了确保纺织厂的防火工作得到有效执行,以下是一些建议:

- 加强消防设施建设和管理,确保其有效性。

- 禁止吸烟和明火作业,严格执行防火规定。

- 加强员工防火安全培训,提高员工的防火意识和技能。

- 定期进行消防演练和应急预案演练,确保员工熟练掌握应对火灾等突发情况的方法。

- 建立完善的防火管理制度和档案,记录防火工作的执行情况。

- 在厂区内设置专门的防火宣传栏,定期更新内容,提醒员工注意防火安全。

- 鼓励使用先进的消防设备和技术,提高防火工作的科技含量。

总结与展望

纺织厂作为生产纺织品的重要场所,其防火工作至关重要,通过制定并执行严格的防火规定,可以确保员工和财产安全,希望本文提供的纺织厂防火规定和相关建议能够对大家有所帮助,随着科技的不断进步,纺织厂的防火工作还将面临更多的挑战和机遇,我们期待纺织厂能够继续加强防火工作,为生产安全和人民生命财产安全做出更大的贡献。

Articles related to the knowledge points of this article:

The Rise of a Viral Infection in the纺织厂女工现象与案例分析

The 22-Year-Old Textile Factory:A Journey Through Youth and Potential