An Overview of Textile Mill Equipment and Its Impact on Production

In this study, we provide an overview of textile mill equipment and its impact on production. Textile mills are essential factories that produce a wide range of textile products such as clothing, carpets, and fabrics. The equipment used in these mills is crucial for the efficient and accurate production of these products.,The most commonly used equipment in textile mills includes looms, spinnerets, and dyeing machines. Looms are used to create woven fabrics while spinnerets are used to create yarns. Dyeing machines are used to apply colors to the fabrics.,The efficiency of these mills depends on the quality and accuracy of the equipment. Poorly maintained or outdated equipment can lead to decreased productivity and increased costs. Therefore, it is important for textile mills to invest in new and modern equipment that can meet the demands of today's market.,In conclusion, textile mill equipment plays a significant role in the production of textile products. Proper maintenance and upgrading of these equipment can improve productivity and reduce costs.

Introduction: Textile mills are vital centers of the global textile industry, responsible for producing a wide array of fabrics, garments, and other textile products. The success of these factories is directly linked to the quality and efficiency of their equipment. In this article, we will explore the various types of textile mill equipment, including machinery, tools, and technology used in the production process. We will also discuss how these pieces of equipment impact the overall production process and the end product. By the end of this article, you will have a comprehensive understanding of the equipment utilized in textile mills and its role in driving productivity and innovation.

Machinery: Textile mills rely heavily on machinery to transform raw materials into finished products. Here are some of the most commonly used machines:

-

Spinning Machines: These machines spin yarn from cotton, wool, or synthetic fibers into thread. They come in different sizes and speeds depending on the type of yarn being produced.

-

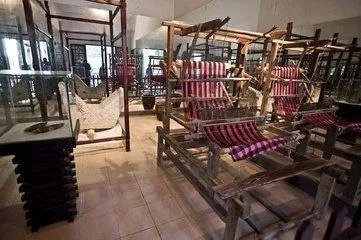

Weaving Machines: These machines create woven fabrics by interlacing threads in a grid pattern. They can be manual or powered, with different types of looms suitable for different types of fabrics.

-

Drafting Machines: These machines use a rotating drum to draw threads onto a cloth-like material, creating patterns that can later be transferred to a piece of fabric.

-

Drawn Thread Machines: These machines use a series of rollers to stretch and shape threads before they are cut into individual strands.

-

Cutting Machines: These machines remove excess yarn from the fabric, leaving it ready for further processing.

-

Pressing Machines: These machines apply pressure to the fabric to remove air bubbles and improve its texture.

-

Sizing Machines: These machines add a protective coating to the fabric to enhance its durability and appearance.

-

Finishing Machines: These machines apply finishing treatments such as dyeing, printing, and finishing to enhance the color and texture of the fabric.

Technology: In addition to traditional machinery, modern textile mills employ cutting-edge technology to improve efficiency and quality. Some examples include:

-

Computer-Aided Design (CAD) software: This software helps designers create detailed drawings of the final product before it is produced.

-

Computer-Aided Manufacturing (CAM) systems: These systems automate parts of the manufacturing process, reducing errors and increasing efficiency.

-

Automated Quality Control (AQC) systems: These systems monitor the quality of the final product throughout the production process, ensuring consistency and accuracy.

-

Internet of Things (IoT) devices: These devices enable real-time monitoring and control of the production process, allowing operators to make quick adjustments when needed.

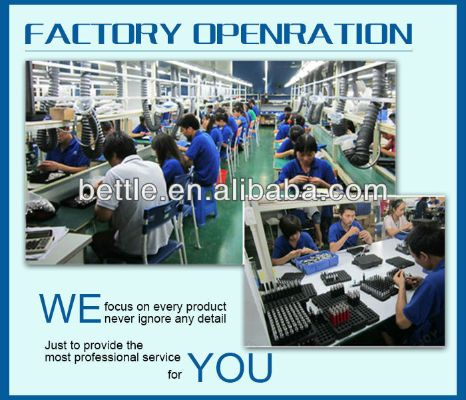

Case Study: One example of the impact of technological advancements in textile mills is the use of robotic weaving machines in China's largest textile factory, Hengli Group. Since the introduction of these machines, the company has been able to increase production capacity by up to 30% while simultaneously reducing labor costs and improving product consistency. Additionally, the use of IoT devices has allowed Hengli Group to optimize its production schedule, minimizing downtime and increasing operational efficiency.

Impact on Production Process: The equipment used in textile mills plays a crucial role in the production process. Each machine contributes to the overall efficiency and quality of the final product. For example, spinners are essential for converting raw materials into yarn, which is then woven into fabric. Similarly, drafting machines help create intricate patterns that can later be transferred to a piece of fabric.

In addition to the direct impact of each machine, the overall setup of the mill also influences the production process. For instance, if there is an imbalance in the distribution of resources among different machines, it may lead to bottlenecks or delays in the production line. To avoid this, manufacturers often invest in advanced inventory management systems and predictive analytics to ensure smooth operation across all stages of the production process.

Conclusion: In conclusion, textile mills rely heavily on a range of equipment to produce high-quality fabrics and garments. From spinning machines to automated quality control systems, each piece of equipment plays a critical role in the overall production process. As technology continues to advance, we can expect even more sophisticated equipment to emerge, further enhancing productivity and driving innovation in the textile industry. By understanding the impact of different types of equipment on the production process, we can better appreciate the importance of investing in the latest technologies and maintaining a competitive edge in the global market.

本报告旨在详细介绍纺织厂的主要设备及其配置情况,以便更好地了解设备的运行状况和维护需求,以下为纺织厂设备明细报告的主要内容:

设备名称

纺织机械类设备

a. 高速织布机 b. 针织机 c. 染整机械 d. 烘干设备 e. 卷布机 f. 其他辅助设备

电气系统

a. 电源设备 b. 控制设备 c. 传感器与执行器 d. 电缆与连接器 e. 自动化系统

具体设备明细及案例说明

纺织机械类设备明细

(一)高速织布机

设备型号:XYZ高速织布机 配置参数:高速织布机配备先进的控制系统,可实现自动化生产,提高生产效率,该机型采用高效电机和精密齿轮,确保织布平整、均匀,该设备具备多种功能模块,可根据不同产品需求进行定制。 案例:某纺织厂使用XYZ高速织布机成功提高了生产效率,降低了人工成本,该厂采用自动化控制系统,实现了高效、稳定的生产,同时减少了人工干预,提高了产品质量,该设备还具备节能环保的特点,符合现代纺织企业的生产需求。

(二)针织机

设备型号:YY针织机 配置参数:针织机采用高效节能电机和精密针布,确保针织产品质量和稳定性,该机型适用于各种针织面料的生产,可根据客户需求定制生产不同规格和款式的针织面料。 案例:某大型纺织企业采用YY针织机成功提高了生产效率和质量,满足了客户多样化的需求,该企业通过与供应商合作,实现了高效的生产流程和稳定的供货能力,该企业还注重环保和节能,符合现代纺织企业的发展趋势。

电气系统明细及案例说明

(一)电源设备明细

设备型号:UPS电源系统 配置参数:UPS电源系统主要用于保障纺织厂电力供应的稳定性和可靠性,该系统采用先进的逆变技术和充电技术,能够快速充电并保持稳定的输出电压和电流,该系统还具备过载保护、短路保护等功能,确保电力系统的安全性和稳定性。 案例:某纺织厂在电力供应不稳定的情况下,采用了UPS电源系统保障了生产线的稳定运行,该厂通过合理的配置和使用UPS电源系统,实现了电力供应的稳定性和可靠性,为生产提供了可靠的保障,该厂还注重节能环保,符合现代纺织企业的发展趋势。

(二)控制设备明细及案例说明

控制设备包括PLC控制系统和触摸屏控制系统等,PLC控制系统主要用于实现设备的自动化控制和监控,某纺织厂采用了先进的PLC控制系统,实现了设备的自动化控制和智能化管理,该厂通过PLC控制系统的使用,提高了生产效率和产品质量,降低了人工成本,该厂还注重环保和节能,符合现代纺织企业的发展趋势。

结论与建议

通过对纺织厂设备明细的详细介绍和分析,可以看出纺织厂在设备配置方面具有较高的水平和优势,在今后的生产和运营中,应注重设备的维护和保养,提高设备的运行效率和稳定性,应注重设备的节能环保和智能化管理,符合现代纺织企业的发展趋势,还应加强与供应商的合作和交流,提高生产效率和产品质量。

Articles related to the knowledge points of this article:

Transforming Textile Industry:The Case of Haiqi Textile Factory

The Story of a Textile Mill:a Small Lu Textile Factory

The Story of a Textile Manufacturer:泰恒纺织厂

The Efficient Operation of Textile Factory Water Shroud Fan System