The Role of Testing Services in Textile Industry

Testing services play a crucial role in the textile industry, providing critical quality assurance and product validation. These services involve various stages of inspection, including initial sampling, detailed analysis of physical properties such as strength and durability, and testing for colorfastness and washability. Additionally, they offer specialized testing for materials like synthetic fibers, which require specialized equipment and expertise. The results of these tests can help manufacturers identify potential issues early on, reducing costs associated with defective products and improving overall efficiency. In summary, testing services are integral to ensuring the quality and reliability of textile products, contributing to the success and sustainability of the industry.

Introduction: The textile industry is one of the largest and most diverse sectors globally, with a significant impact on global economic growth and employment. As such, the quality and performance of textile products are crucial for the success of this industry. One of the critical components of ensuring product quality is through rigorous testing services that ensure products meet the required standards and specifications. In this article, we will discuss the role of testing services in the textile industry, including their importance, types of testing, and how they contribute to product quality.

Importance of Testing Services in Textile Industry: Testing services play a crucial role in the textile industry as they help identify defects, evaluate performance, and ensure compliance with regulatory requirements. These services are essential for preventing defects from reaching the end consumer, reducing costs associated with recalls or product failures, and enhancing customer satisfaction. By providing accurate and reliable results, testing services also enable manufacturers to make informed decisions about product development and production processes.

Types of Testing Services in Textile Industry: There are several types of testing services used in the textile industry, each aimed at evaluating different aspects of product performance. Here are some common types of testing services:

-

Quality Control Testing: This type of testing is carried out during the manufacturing process to ensure that products meet the required quality standards. Quality control testing includes inspections for defects, measurements, and other parameters that affect product performance and safety.

-

Product Testing: This involves conducting tests on finished products to evaluate their performance against specific standards or specifications. Product testing may include mechanical testing, chemical testing, and environmental testing to ensure products meet the required standards.

-

Environmental Testing: Environmental testing is an important part of the textile industry as it ensures products comply with regulations regarding materials, packaging, and disposal. This type of testing includes tests for toxicity, biodegradability, and other environmental concerns.

-

Compliance Testing: This type of testing is conducted to ensure products meet regulatory requirements for specific industries or markets. Compliance testing may involve testing for specific chemicals, dyes, or finishes that are required by regulatory bodies.

-

End-of-Life Testing: End-of-life testing is a critical component of the textile industry as it helps determine whether products can be safely disposed of without causing harm to the environment or human health. This type of testing involves assessing the environmental impact of products after they have been used and discarded.

How Testing Services Contribute to Product Quality: Testing services play a vital role in ensuring the quality of textile products by identifying defects, evaluating performance, and ensuring compliance with regulatory requirements. Here are some ways testing services contribute to product quality:

-

Identifying Defects: Testing services help detect defects in raw materials, intermediate products, and finished products. Early detection of defects allows manufacturers to take corrective action before products reach the market, reducing the risk of defective products being sold to customers.

-

Ensuring Performance: Testing services evaluate the performance of products against specific standards or specifications. This information helps manufacturers make informed decisions about product development and production processes, ensuring products meet the required standards and specifications.

-

Ensuring Compliance: Testing services ensure products meet regulatory requirements for specific industries or markets. Compliance testing helps prevent products from being banned or recalled due to unsafe or illegal ingredients or practices, protecting consumers and the industry's reputation.

-

Ensuring Environmental Safety: Environmental testing ensures products are safe for use and disposal without causing harm to the environment or human health. This type of testing helps protect the environment and minimize the risks associated with hazardous materials and practices.

-

Ensuring Longevity: End-of-life testing helps determine whether products can be safely disposed of without causing harm to the environment or human health. This type of testing helps ensure that products are properly recycled or disposed of, minimizing the environmental impact of products that end up in landfills or waterways.

Conclusion: In conclusion, testing services play a critical role in the textile industry as they help identify defects, evaluate performance, and ensure compliance with regulatory requirements. By providing accurate and reliable results, testing services enhance product quality, reduce costs associated with recalls or product failures, and enhance customer satisfaction. As the textile industry continues to evolve and become more competitive, the importance of testing services will only continue to grow, enabling manufacturers to produce high-quality products that meet the needs of consumers and industry stakeholders.

纺织厂测试服务概述

大家好,今天我们将探讨纺织厂测试服务的重要性及其在生产过程中的作用,在纺织行业中,纺织厂测试服务不仅关乎产品质量,更是确保生产效率和客户满意度的关键环节,下面我们将从几个方面详细介绍纺织厂测试服务的相关内容。

纺织厂测试服务流程

材料准备阶段

在纺织厂测试服务中,材料准备阶段是至关重要的环节,这包括对原材料进行检测,确保其符合相关标准和规格,测试人员需要仔细检查原材料的纤维类型、长度、质量等参数,以确保其符合生产要求。

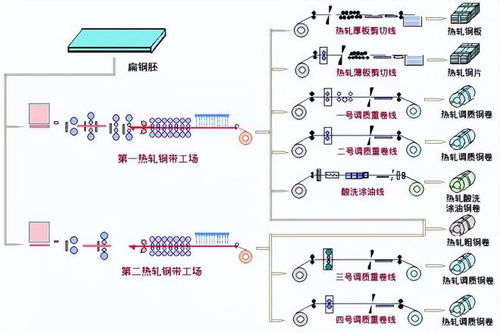

设备调试阶段

在设备调试阶段,测试人员需要对生产设备进行全面检查和测试,这包括对纺丝机、织布机等关键设备的性能进行测试,确保其能够正常运转并达到生产要求,测试人员还需要对设备的控制系统进行测试,以确保其能够准确控制设备的运行参数。

样品制作与送检阶段

在样品制作与送检阶段,测试人员需要根据生产计划和客户需求,制作相应的样品,样品需要符合相关标准和规格,以确保其能够真实反映产品的性能和质量,样品制作完成后,需要按照相关流程将样品送往第三方检测机构进行检测。

案例分析:纺织厂测试服务的成功实践

下面我们将通过一个案例来详细说明纺织厂测试服务的成功实践,某纺织厂在生产过程中遇到了产品质量问题,为了解决这一问题,该厂引入了专业的纺织厂测试服务。

案例:某纺织厂的质量提升之旅

该纺织厂在引入纺织厂测试服务之前,产品质量一直存在波动,为了解决这一问题,该厂决定引入专业的纺织厂测试服务团队,测试团队对原材料进行了全面检测,对生产设备进行了全面检查和测试,同时还对生产工艺进行了优化,经过一段时间的测试和优化,该厂的产品质量得到了显著提升,客户满意度也得到了显著提高。

纺织厂测试服务的具体细节说明

-

材料检测:测试人员需要对原材料进行全面的检测,包括纤维类型、长度、质量等参数,他们需要使用专业的检测设备和方法,以确保检测结果的准确性和可靠性。

-

设备性能测试:测试人员需要对生产设备进行全面的性能测试,包括设备的稳定性、精度、效率等参数,他们需要使用专业的测试仪器和方法,以确保设备的性能达到生产要求。

-

样品制作与送检流程:测试人员需要根据生产计划和客户需求,制作相应的样品,样品需要符合相关标准和规格,以确保其能够真实反映产品的性能和质量,样品制作完成后,需要按照相关流程将样品送往第三方检测机构进行检测,检测结果出来后,测试人员还需要对检测结果进行分析和处理,为生产提供参考和建议。

纺织厂测试服务在纺织行业中具有至关重要的作用,它不仅关乎产品质量和生产效率,更是确保客户满意度的关键环节,通过专业的纺织厂测试服务团队的努力和合作,纺织厂的产品质量得到了显著提升,生产效率和客户满意度也得到了显著提高,专业的纺织厂测试服务还可以帮助企业及时发现和解决生产过程中的问题,为企业的发展提供有力支持。

Articles related to the knowledge points of this article:

The Evolution of Zhejiang Oak Tree Textile Factory

The Transformative Journey of Fujian Textile Factory at the Street Market