Textile Disease Standards and Their Impact on Quality Control

: Textile Disease Standards and Their Impact on Quality Control,Abstract:,Textile diseases, such as moth damage, pest infestation, and dye discoloration, pose significant challenges to quality control in the textile industry. This paper discusses the importance of establishing and adhering to textile disease standards, which are essential for ensuring product consistency and consumer satisfaction. The impact of these standards on quality control is examined, including their role in preventing defects, minimizing waste, and enhancing product reliability. The paper also highlights the benefits of implementing effective quality control measures, such as regular inspections, training programs, and technology advancements, that can further improve the efficiency and effectiveness of textile disease management. Overall, the adoption of textile disease standards is crucial for maintaining high-quality products and ensuring sustainable growth in the textile industry.

In the world of textiles, maintaining high standards for quality control is critical to ensuring consumer satisfaction and maintaining brand reputation. One crucial aspect of this is the adherence to industry-specific disease standards that govern the acceptance of defective products. These standards are designed to prevent harmful substances from entering the market and protect consumers from potential health risks. In this article, we will explore the importance of textile disease standards and how they are implemented in various industries.

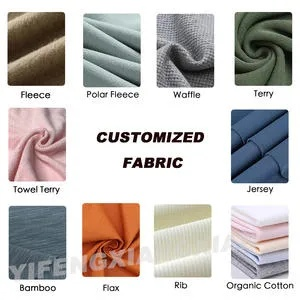

Textile diseases refer to a variety of conditions that affect textile materials, including color changes, shrinkage, wrinkles, and structural damage. These issues can arise due to various factors such as improper dyeing processes, chemical contamination, or environmental stresses like heat, humidity, and light exposure. The severity of these diseases can vary depending on the type of fabric and its intended use, but their impact on product quality cannot be overstated.

One of the most significant benefits of implementing textile disease standards is the prevention of harmful substances from entering the market. For example, in the apparel industry, color-fastness testing is an essential part of the manufacturing process. This test measures how well a dye resists washing and rubbing, which helps to ensure that garments do not fade or lose their colors over time. By requiring manufacturers to meet specific color-fastness standards, the industry can reduce the risk of consumers receiving defective products.

Another important aspect of textile disease standards is the protection of consumers' health. For instance, in the home textiles industry, there have been cases where synthetic fibers were found to contain harmful chemicals that could leach into the air during use. By implementing strict standards for the use of these materials, manufacturers can minimize the risk of exposure and provide safer products for consumers.

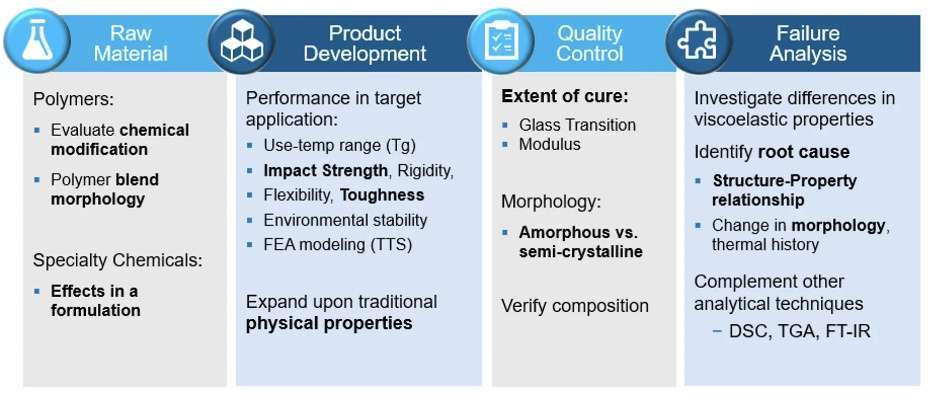

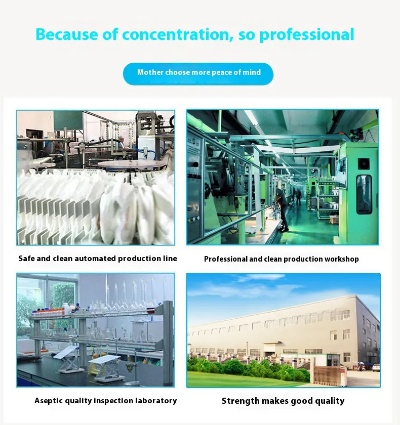

To achieve these goals, many textile companies invest in advanced testing facilities that employ sophisticated technology to detect and quantify textile diseases. For example, some companies use machine vision systems to analyze images taken under different lighting conditions, while others use X-ray techniques to identify hidden defects within the fabric. These methods help manufacturers to identify potential problems early on in the production process and take corrective actions before final inspection.

However, despite the benefits of these standards, there are still challenges that need to be addressed. One of the main obstacles is the lack of uniformity across different regions and countries in terms of regulations and standards. This can make it difficult for manufacturers to comply with international requirements and ensure that their products meet global quality standards.

Another challenge is the increasing complexity of textiles, which means that new diseases and treatments are emerging all the time. Manufacturers must stay up-to-date with the latest research and developments in order to maintain compliance with evolving standards. Additionally, there is often a need for more stringent testing methods that can detect even smaller defects, which can be challenging to achieve without expensive equipment and expertise.

Despite these challenges, the importance of textile disease standards cannot be overstated. By setting clear guidelines and establishing rigorous testing protocols, manufacturers can ensure that their products meet the highest quality standards and provide consumers with safe and reliable products. As the textile industry continues to evolve, it is vital that industry stakeholders work together to develop and implement effective disease standards that support sustainable growth and innovation.

In conclusion, textile disease standards play a crucial role in ensuring the quality and safety of textile products. By adhering to these standards, manufacturers can reduce the risk of harmful substances entering the market and protect consumers from potential health risks. As the industry continues to grow and evolve, it is essential that industry stakeholders work together to develop and implement effective disease standards that support sustainable growth and innovation. With proper implementation and enforcement, textile disease standards can help create a safer and healthier environment for everyone involved in the industry.

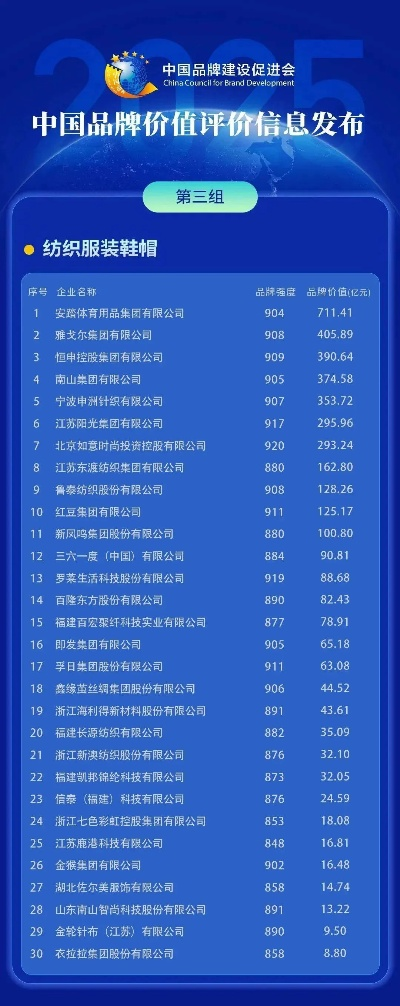

随着纺织行业的快速发展,纺织品的质量和安全性问题日益受到关注,为了规范纺织品病害防治工作,制定纺织品病害标准显得尤为重要,本篇文章将围绕纺织品病害标准展开讨论,并通过英文案例说明来进一步阐述。

纺织品病害标准概述

定义与分类

纺织品病害标准是指对纺织品在生产、加工、运输、储存等环节中可能出现的病害进行规范和检测的标准,根据不同的分类标准,纺织品病害可分为多种类型,如霉变、虫蛀、色差、异味等。

纺织品病害标准主要包括以下几个方面:

(1)检测方法:规定了检测纺织品病害的仪器、试剂、操作流程等。

(2)检测标准:明确了不同类型病害的检测指标和标准。

(3)处理措施:规定了纺织品病害的防治措施和处置方法。

英文案例说明

某纺织企业纺织品质量检测标准实施情况

某纺织企业为了确保纺织品的质量和安全性,制定了详细的纺织品病害标准,该企业采用了先进的检测设备和专业的检测人员,严格按照标准进行纺织品检测,在检测过程中,该企业采用了高效、准确的检测方法,确保了检测结果的准确性,该企业还制定了相应的处理措施,对出现病害的纺织品进行了及时处理,避免了产品问题的出现。

纺织品病害标准在实际应用中的效果评估

在实际应用中,纺织品病害标准取得了显著的效果,通过实施纺织品病害标准,该企业的纺织品质量得到了有效保障,消费者对该企业的产品信任度得到了提高,该企业的产品也得到了国内外市场的认可,销售量逐年上升,该企业的生产流程得到了优化,提高了生产效率和质量。

纺织品病害标准补充说明

检测方法与仪器

(1)霉菌检测:采用光学显微镜观察法或培养法进行检测。

(2)虫蛀检测:采用X射线荧光光谱仪或显微镜观察法进行检测。

(3)色差检测:采用色差计进行测量和分析。

(4)其他常见病害检测:根据实际需要选择相应的检测方法和技术。

检测标准与指标

(1)霉菌检测标准:霉菌数量应在一定范围内,且无明显的霉菌生长迹象。

(2)虫蛀检测指标:虫蛀率应在一定范围内,且虫蛀部位应符合相关标准要求。

(3)色差检测指标:色差值应在一定范围内,且颜色应符合相关标准要求。

处理措施与建议

(1)对于出现病害的纺织品,企业应立即采取相应的处理措施,如清洗、修补、更换等,企业还应加强质量管理,提高生产过程中的质量控制水平。

(2)对于不符合标准的纺织品,企业应加强宣传和教育,提高消费者对产品质量的认识和信任度,企业还应加强与相关部门的沟通和协调,共同推动纺织行业健康发展。

纺织品病害标准的制定和实施对于保障纺织品质量和安全性具有重要意义,通过制定详细的纺织品病害标准,企业可以更好地进行纺织品检测和处置,提高产品质量和竞争力,纺织品病害标准的实施还可以促进纺织行业健康发展,提高消费者对产品质量的认识和信任度,我们应该加强对纺织品病害标准的制定和实施工作,推动纺织行业健康发展。

Articles related to the knowledge points of this article:

A Comprehensive Look at Morning Sun Textiles From Origin to Success

Exploring the Beauty of Fuman Textiles:A Comprehensive Guide

Exploring the World of Yarn:A Journey to Understanding Yiyi Textiles