The Intricacies of Textile Mill Weaving and Thread Management

"The Intricacies of Textile Mill Weaving and Thread Management",This article explores the complexities of textile mill weaving and thread management. It discusses the various techniques used in creating intricate patterns on fabric, such as cross-stitching, embroidery, and knitting. The article also delves into the importance of proper thread management in achieving a high-quality finished product. It highlights the challenges faced by textile mills in managing a large number of threads and ensuring that they are properly organized and stored. By understanding the intricacies of textile mill weaving and thread management, we can improve our skills and create beautiful and durable products.

Introduction The textile industry is a multifaceted sector that involves the production of a wide range of fabrics, from cotton to synthetic materials. One of the most crucial components of this process is the weaving process, which involves the interlacing of threads onto a warp thread to create the cloth. The success of this process hinges on the quality of the thread, which must be precisely managed throughout the entire manufacturing process. This essay will explore the intricacies of thread management in a textile mill, including the importance of proper thread selection, storage, handling, and use during the weaving process.

Proper Thread Selection The first step in managing thread in a textile mill is ensuring that it meets specific requirements for quality, strength, and durability. Textile manufacturers often use a variety of materials, including polyester, nylon, and viscose, depending on the type of fabric they are producing. For example, a polyester thread may be used for a soft, lightweight fabric, while a nylon thread may be more suitable for a durable, heavy-duty garment.

In addition to material selection, the manufacturer must also consider thread diameter, count, and weight when selecting the right thread for their product. A larger diameter or higher count thread may be required for thicker fabrics or heavier items, while a lighter thread may be more suitable for delicate or lightweight fabrics. The weight of the thread can also affect its performance in the weaving process, with heavier threads being more resistant to breakage and less prone to slipping.

Storage and Handling Once the thread has been selected and prepared, it must be stored properly to prevent damage or contamination. Textile manufacturers typically have specialized storage facilities for their thread products, which are designed to maintain the integrity of the threads and prevent any potential contaminants from entering the facility.

The storage conditions for thread can vary depending on the manufacturer's specifications, but generally include temperature control, humidity regulation, and regular inspections to ensure that the threads remain in good condition. For example, some manufacturers may opt for refrigeration to slow down the deterioration of the thread over time, while others may store the threads in a dry environment to prevent moisture damage.

Handling of Thread During Weaving Once the thread is stored and ready for use, it must be handled with care during the weaving process. This includes loading the thread into the machine, feeding it through the loom, and monitoring its progress during the weaving cycle.

Loading the Thread Before starting the weaving process, the manufacturer must carefully load the thread into the machine. This requires precise measurements and alignment of the threads to ensure that they are evenly distributed across the warp threads. The manufacturer must also ensure that the threads are properly secured in place, with no loose ends or tangles that could cause issues during the weaving process.

Feeding the Thread Once the thread is loaded into the machine, it must be fed through the loom in a controlled manner. This requires careful monitoring to ensure that the threads are moving smoothly and not causing any interference with the other components of the loom. The manufacturer must also ensure that the threads are feeding at a consistent speed and that there are no gaps or holes in the thread path.

Monitoring the Thread During Weaving During the weaving process, the manufacturer must closely monitor the thread's progress to ensure that it is functioning correctly. This includes checking for any signs of wear or damage, such as fraying or breaking, and adjusting the settings of the loom if necessary to prevent these issues from occurring.

Using the Thread After Weaving Once the weaving process is complete, the manufacturer must carefully remove the thread from the loom and store it properly. This requires careful handling to prevent any damage or contamination during transportation or storage. The manufacturer must also ensure that the thread is properly labeled and organized to facilitate future use.

Conclusion Textile mills rely heavily on thread management to ensure the success of their weaving operations. From selecting the right thread materials and dimensions to storing and handling the thread during the weaving process, proper thread management is essential for producing high-quality fabrics. By following best practices and maintaining strict standards for thread quality and handling, textile manufacturers can minimize errors and improve overall efficiency.

大家好,今天我们将探讨一个与纺织厂织布紧密相关的主题——引线,在纺织行业飞速发展的今天,纺织厂织布行业正迎来新的机遇与挑战,本文将通过案例分析、图表说明以及口语交流的方式,为大家揭示纺织厂织布引线的奥秘。

纺织厂织布概述

纺织厂织布是传统产业的重要组成部分,主要涉及棉、麻、丝等天然纤维的织造工艺,随着科技的不断进步和消费者需求的不断升级,纺织厂织布行业正朝着高效、环保、智能化的方向发展。

引线的重要性

引线在纺织厂织布中扮演着至关重要的角色,它不仅关系到织布的效率和品质,还影响着整个纺织产业链的可持续发展,通过优化引线设计,可以降低生产成本、提高生产效率,同时也有助于实现绿色生产、环保生产。

案例分析

以某知名纺织厂为例,其成功运用引线技术,实现了高效、环保、智能化的织布生产,该纺织厂采用了先进的织布机和技术,优化了引线设计,使得织布效率得到了显著提升,该厂还注重绿色生产,采用环保材料和工艺,实现了生产过程的绿色化,该厂还积极拓展市场,提高了产品的附加值和市场竞争力。

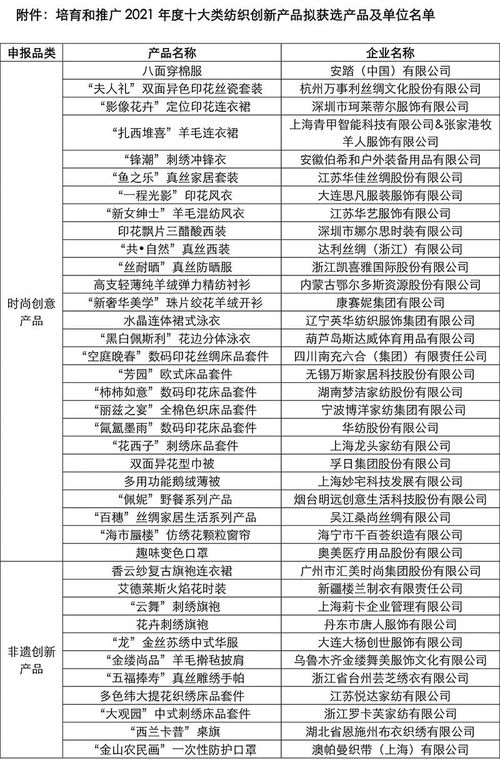

图表说明

以下是关于纺织厂织布引线的图表说明:

图表1:纺织厂织布引线优化设计图

【数据来源】:某知名纺织厂实际数据 :优化后的引线设计图,包括引线长度、宽度、张力等参数的调整。

【:通过优化引线设计,可以显著提高织布效率、降低生产成本,同时也有助于实现绿色生产、环保生产。

口语交流示例

A:大家好,今天我们来聊聊纺织厂织布引线的话题,你知道什么是引线吗?

B:当然知道,引线是纺织厂织布的关键环节之一,它关系到织布的效率和品质。

A:没错,引线的设计和优化对于整个纺织产业链的可持续发展有着至关重要的作用,你们是如何运用引线技术的呢?

C:我们纺织厂采用了先进的织布机和技术,优化了引线设计,我们通过调整引线的长度、宽度和张力等参数,实现了更高的织布效率,我们也注重绿色生产,采用环保材料和工艺,实现了生产过程的绿色化,我们还积极拓展市场,提高了产品的附加值和市场竞争力。

D:看来你们在这方面做得不错啊!你们还有其他关于纺织厂织布的案例或者经验分享吗?

纺织厂织布引线是纺织行业发展的重要组成部分,通过优化引线设计和技术应用,可以降低生产成本、提高生产效率,同时也有助于实现绿色生产、环保生产,在未来的发展中,纺织厂织布行业将继续朝着高效、环保、智能化的方向发展,我们期待更多的纺织厂能够运用引线技术,推动纺织行业的发展和进步。

Articles related to the knowledge points of this article:

The Life and Business of Qian County Textile Factory Owner

The Global Challenges and Opportunities Faced by Textile Factories

A Brief Tour of the Binzhou Zoucheng Textile Factory

Navigating the World of Textiles:A Guide to Entering a Textile Factory