The Science Behind Medical Textiles:An Illustrated Guide to Dyeing Principles

: Understanding the Science Behind Medical Textiles - An Illustrated Guide to Dyeing Principles,Abstract:,Medical textiles, such as surgical gloves and hospital gowns, are crucial in preventing infection and maintaining patient safety. However, their efficacy is often attributed to the dyeing principles used in these fabrics. In this guide, we explore the science behind the dyeing of medical textiles, including the importance of color fastness, water resistance, biohazardous substances, and toxicity. By understanding these principles, healthcare professionals can make informed decisions when selecting and using medical textiles.

I. Introduction Textiles, particularly those used in healthcare, have become increasingly important in modern medicine. From surgical gowns to hospital gowns, medical textiles play a crucial role in protecting patients from infections and maintaining patient hygiene. One of the critical aspects of these textiles is their ability to resist staining and maintain their integrity over time. This paper will delve into the scientific principles behind the dyeing of medical textiles and provide practical insights into how they are prepared for use in hospitals and other medical settings.

II. Dyeing Principles

Dyeing is the process by which pigments are incorporated into textile fibers to alter their color. In the case of medical textiles, dyeing is done not just to create aesthetically pleasing colors but also to enhance the performance properties of the fabric. These properties include stain resistance, water-fastness, and biocompatibility.

-

Pigments and Dyes: Dyes are organic compounds that absorb light in the visible spectrum and emit it in another form, typically as a colored light. They come in various forms, including direct dyes, reactive dyes, vat dyes, and more. Each type has different properties and applications, such as fastness to light and heat, washability, and ease of application.

-

Coating Techniques: There are several coating techniques that can be used to apply dyes to medical textiles. These include pad printing, screen printing, spraying, and gravure printing. Each technique offers unique advantages and limitations, such as higher accuracy with screen printing and faster production times with pad printing.

-

Chemical Processes: The dyeing process itself involves complex chemical reactions between the dye and the textile material. Common chemicals used include oxidizers, reducing agents, pH adjusters, and fixatives. The precise formulation of these chemicals is key to achieving optimal dyeing results.

III. Application of Dyeing Principles in Medical Textiles

The application of dyeing principles to the manufacture of medical textiles is crucial for ensuring their efficacy and safety. Below are some practical examples of how these principles are used in the production process.

Direct Dyeing: Direct dyeing is a simple and cost-effective method for applying dye directly to medical textiles. Here’s an example table outlining the steps involved:

| Step | Action |

|---|---|

| Pretreatment of the textile | Remove excess moisture and impurities. |

| Adding aqueous solution of direct dye to the textile | Disperses the dye throughout the fibers. |

| Applying pressure and heat | Dries the dye and fixes it to the fibers. |

| Treating with alkali (optional) | Removes any excess unfixed dye. |

Reactive Dyeing: Reactive dyes react with the fiber's amino groups or carboxyl groups to produce stable dye molecules. A typical dye bath setup for reactive dyeing might look like this:

| Step | Action |

|---|---|

| Adding the reactive dye to the textile | Allows it to penetrate into the fiber structure. |

| Adding ammonia or other reagent (if necessary) | Acts as a catalyst for the dye reaction. |

| Treating with alkali (optional) | Removes any residual unreacted dye. |

IV. Challenges in Dyeing Medical Textiles

While the science behind medical textile dyeing is straightforward, there are challenges that need to be overcome to ensure consistent quality and safety. Some of these challenges include:

-

Variability in Fiber Type and Quality: Different types of medical textile fibers have different levels of absorbency and stability. For instance, polyester fibers may absorb less dye compared to natural fibers like cotton. This variability needs to be addressed to achieve consistent dye uptake and uniform appearance.

-

High-Quality Requirements: Medical textiles must meet strict standards of biocompatibility, sterility, and non-toxicity. These requirements necessitate stringent dye selection and processing protocols to avoid any adverse reactions or health risks.

-

Environmental Considerations: The manufacturing process should minimize the use of harmful chemicals, minimizing environmental impact. Additionally, proper waste management practices are essential to protect the environment during the dyeing process.

V. Future Trends in Dyeing Medical Textiles

As technology advances, we can expect new advancements in the field of dyeing medical textiles. Some promising developments include:

-

Advanced Dye Technology: The introduction of new dyeing technologies like UV curable dyes or nanotechnology could lead to faster and more efficient dyeing processes. These technologies could potentially reduce waste and improve yield rates.

-

Sustainable Dyeing Practices: As concerns about sustainability grow, research is being done on eco-friendly alternatives to traditional dyeing methods. These alternatives aim to minimize the use of toxic chemicals while still producing high-quality products.

By understanding the science behind medical textile dyeing and addressing its challenges, we can further improve the safety and efficacy of these critical products. As industry experts continue to push the boundaries of innovation, we can expect to see even more exciting breakthroughs leading to safer, more effective medical textiles.

医用纺织品作为医疗领域中的重要组成部分,其质量直接关系到患者的安全和治疗效果,染色技术在医用纺织品生产中扮演着至关重要的角色,其原理决定了染料的选用、染色工艺以及最终产品的性能,本文将深入探讨医用纺织品的染色原理,并通过案例分析进一步说明。

医用纺织品染色原理

染料选择

医用纺织品染色主要采用天然或合成染料,天然染料具有环保、安全、无刺激等特点,适用于各种材质的医用纺织品,合成染料则具有色泽鲜艳、着色力强等优点,适用于不同材质和颜色的需求。

染色原理

染色原理主要涉及染料的吸收、分散和转移三个步骤,染料需要被吸收到纤维或织物中,使其与纤维或织物发生化学反应,染料需要被均匀分散在纤维或织物中,以确保染色效果的一致性和均匀性,染料需要被转移到织物表面,形成所需的颜色和图案。

影响染色的因素

影响染色的因素主要包括纤维材质、织物结构、染料性质、温度和湿度等,纤维材质的不同会影响染料的吸收和分散效果,织物结构的不同会影响染料的转移效果,染料性质的不同也会影响染色效果和产品的性能。

案例分析

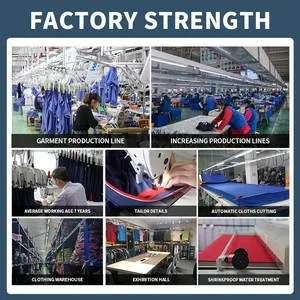

以某医用纺织品公司为例,其生产的医用纺织品采用了特定的染色工艺和技术,该公司的染色工艺采用了天然染料和高温高压染色技术相结合的方式,以达到更好的染色效果和产品的性能。

染色工艺流程

该公司的染色工艺流程主要包括纤维准备、染料添加、高温高压染色三个步骤,公司会对纤维进行预处理,使其达到最佳的染色效果,根据纤维材质和颜色需求,将适量的染料添加到纤维中,使用高温高压染色设备进行染色,确保染料均匀分布在纤维中,形成所需的颜色和图案。

染色效果分析

该公司的染色效果得到了客户的高度认可,采用特定的染色工艺和技术后,医用纺织品的颜色鲜艳、均匀度高,图案清晰可见,该公司的产品还具有环保、安全、无刺激等特点,符合医疗领域的需求。

医用纺织品染色原理涉及到染料选择、染色工艺等多个方面,在染色过程中,需要综合考虑纤维材质、织物结构、染料性质、温度和湿度等因素,不同的染色工艺和技术可以满足不同的需求和要求,在实际生产中,应该根据具体的产品需求和要求选择合适的染色工艺和技术,以达到更好的染色效果和产品的性能。

Articles related to the knowledge points of this article:

The Ultimate Guide to Choosing the Best Materials for Your Fashion Needs

A Journey into the World of Fabrics with Laughing Leaf Textiles

The 2022 Textile Show:A Global Tapestry of Innovation and Sustainability

The Global Textile Expo:An Exploration of the Timetable and Key Events

Embracing Innovation at the Houjie Textile Exhibition

Essential Guidelines for Verifying Furniture amp;Textile Items During Import