An Overview of Textiles R&D Equipment

Textile R&D (Research and Development) is a crucial aspect of the textile industry, as it enables companies to stay ahead in the competitive market. Textile R&D equipment plays a significant role in this process. The primary purpose of R&D equipment is to enable textile companies to conduct research and development activities efficiently. These machines are designed to meet specific requirements, such as high precision, accuracy, and speed. They can be used for various purposes, including testing new materials, developing new designs, and improving existing ones. Some of the commonly used textile R&D equipment includes tensile testers, calipers, yarn tensioners, and dyeing machines. These tools help textile companies to gather valuable data and insights, enabling them to make informed decisions and improve their products. In conclusion, textile R&D equipment is essential for textile companies to stay competitive in the market. It helps them to develop new products, improve existing ones, and gather valuable data for decision-making.

本文目录导读:

In the realm of textile innovation, there is a constant quest for new materials, designs, and processes. To achieve this, textile companies rely heavily on advanced R&D (Research and Development) equipment that enables them to push the boundaries of what's possible in the textile industry. From high-tech machines to sophisticated software tools, these devices play a crucial role in transforming raw materials into high-quality, sustainable textile products. In this guide, we will explore the essential components of textile R&D equipment, their functionalities, and how they contribute to the success of textile companies. Let's dive into the world of textile R&D technology!

Textile R&D Equipment: A Comprehensive Breakdown

Material Testing Equipment

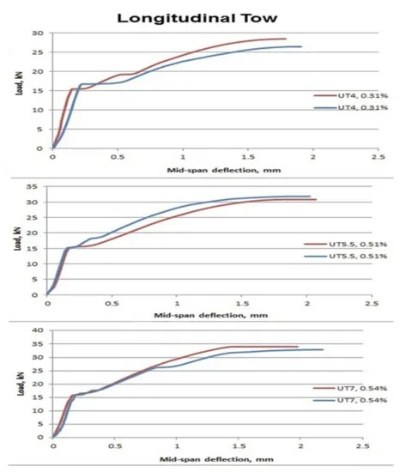

- Tensile Testers: These are essential tools for measuring the strength and resilience of textile materials. They help manufacturers understand how fabrics respond under tension and pressure.

- Elongation Testers: These instruments measure the extent to which textiles can be stretched without breaking. They are crucial for assessing fabric elasticity and durability.

- Density Testers: These tools determine the weight or volume per unit area of a material, providing valuable information about its density and potential for weight reduction.

- Colorimeter: Used to measure the color intensity, hue, and value of textiles, ensuring consistent quality across batches.

- Texture Analyzers: These devices measure the hardness, abrasion resistance, and grip properties of textiles, helping manufacturers design products that meet specific user needs.

Design and Manufacturing Tools

- 3D Printers: Revolutionizing the textile industry by enabling rapid prototyping and customization of complex designs.

- Computer Numerical Control (CNC) Machines: Allowing for precise cutting and shaping of textiles, enhancing product consistency and quality.

- Weaving Machines: The backbone of textile production, capable of creating intricate patterns and designs with precision.

- Spinning Machines: Crucial for producing yarn and fibers, ensuring uniformity and quality control throughout the process.

- Laminating Machines: Used for bonding two or more layers of fabric together, enhancing strength and durability.

Quality Control Instruments

- Quality Inspection Machines: These tools automate the inspection process, ensuring products meet standards and specifications.

- Microbial Analysis Equipment: For monitoring the presence of harmful microorganisms, such as bacteria or fungi, to ensure product safety.

- Chemical Analyzers: Used to test for dyestuffs, additives, and other chemicals used in textile manufacturing, ensuring compliance with environmental regulations.

Software Tools

- CAD Software: Used for designing textile products, facilitating creativity and efficiency in the design phase.

- ERP Systems: Automated systems that manage inventory, orders, and financial transactions, streamlining operations and reducing errors.

- Data Analytics Software: Powerful tools for analyzing data from various sources, identifying trends and patterns, and aiding decision-making in R&D and production.

Case Study: Advancements in Textile Technology

In the textile industry, one company that has made significant strides in R&D equipment is TexTech Innovations. With a focus on sustainability and eco-friendliness, TexTech has developed cutting-edge technologies that enable them to produce textiles from recycled materials. Their innovative use of 3D printing technology allows them to create intricate designs from scrap fabrics, reducing waste and promoting circular economy principles. Additionally, their CNC machines are highly accurate, allowing them to produce high-quality products with minimal waste.

TexTech's commitment to quality control is also evident in their use of advanced quality inspection equipment. By employing automated systems, they can quickly and accurately identify defects in their products, ensuring they meet stringent standards and customer requirements. Furthermore, their adoption of data analytics software has enabled them to analyze vast amounts of data related to their products and processes, leading to improved efficiency and cost savings.

In conclusion, textile R&D equipment plays a crucial role in driving innovation and progress in the industry. From advanced testing tools to advanced manufacturing capabilities, these tools enable textile companies to push the boundaries of what's possible. As we continue to see advancements in technology, it's clear that textile R&D is set to become even more sophisticated and impactful in the years ahead.

在纺织品研发领域,先进的设备是推动技术进步和提升产品质量的关键,本文将详细阐述纺织品研发设备包括哪些内容,并通过英文案例说明来进一步加深理解。

纺织品研发设备概述

纺织品研发设备主要包括以下几种类型:

- 织造设备:用于织造各种纱线、面料和织物的设备,包括针织机、梭织机等。

- 染整设备:用于染色、整理和印花等工艺的设备,包括染色机、印花机、烘干机等。

- 检测设备:用于检测纺织品质量的各种仪器和设备,如拉力测试机、尺寸测量仪等。

- 自动化设备:采用先进技术,实现自动化生产的设备,如智能机器人、数控机床等。

具体设备介绍及案例分析

织造设备

织造设备是纺织品研发的基础设施,用于生产各种纱线、面料和织物,以下是一些常见的织造设备及其案例:

(1)针织机:针织机是一种高效、环保的织布设备,广泛应用于各种纺织品生产中,某知名品牌的一款针织机采用了先进的智能控制系统,能够根据不同的面料和产品需求进行灵活调整,大大提高了生产效率和产品质量。

(2)梭织机:梭织机是一种大规模生产各种面料和服装的设备,具有高产量、高效率的特点,某大型纺织企业采用了先进的梭织机技术,实现了从原材料到成品的快速转化,大大提高了生产效率。

染整设备

染整设备主要用于染色、整理和印花等工艺,以下是染整设备的具体案例:

(1)染色机:染色机是一种用于染色处理的设备,具有高精度、高效率的特点,某知名品牌的一款染色机采用了先进的染色技术,能够根据不同的面料和颜色需求进行精准染色,大大提高了染色效果和产品质量。

(2)印花机:印花机是一种用于印花处理的设备,能够根据不同的图案和设计需求进行灵活调整,某时尚品牌采用了先进的印花技术,能够生产出各种精美图案的纺织品,满足了市场的多样化需求。

检测设备案例

检测设备是纺织品研发过程中不可或缺的一部分,用于检测纺织品的质量和性能,以下是一些常见的检测设备的案例:

(1)拉力测试机:拉力测试机是一种用于测试纺织品拉伸性能的设备,能够准确测量纺织品的抗拉强度、弹性等性能指标,某知名品牌的一款拉力测试机采用了先进的拉力测试技术,能够准确测量纺织品的各项性能指标,为产品的质量控制提供了有力保障。

(2)尺寸测量仪:尺寸测量仪是一种用于测量纺织品尺寸的设备,能够快速准确地测量纺织品的尺寸规格,某服装品牌采用了先进的尺寸测量技术,能够快速准确地测量生产过程中的纺织品尺寸,保证了产品的质量和一致性。

纺织品研发设备是纺织品研发过程中不可或缺的一部分,涵盖了织造设备、染整设备和检测设备等多种类型,不同的设备和案例在不同的纺织品研发过程中发挥着不同的作用,随着科技的不断进步和市场需求的变化,纺织品研发设备的性能和功能也在不断升级和完善,在纺织品研发过程中,应该根据实际需求选择合适的设备和案例,以提高纺织品的质量和产量。

Articles related to the knowledge points of this article:

The Characteristics of the纺织服装行业

Unlocking the Benefits of EPR Compliance for French Textile Exporters