The Role of Textile Dyeing and Processing in Fashion Industry

In the fashion industry, textile dyeing and processing play a crucial role in creating unique designs and enhancing the overall appearance of garments. This process involves selecting appropriate colors, designing patterns, and applying different finishing techniques to achieve desired results. Textile dyeing and processing not only add color and vibrancy to fabrics but also help to create textures, patterns, and finishes that enhance the aesthetic appeal of clothing.,The use of innovative dyeing techniques such as digital printing, embroidery, and screen-printing has revolutionized the fashion industry by allowing designers to create intricate and detailed designs on fabrics with ease. These techniques not only save time and resources but also provide flexibility in terms of design and production.,Moreover, the importance of sustainable practices in textile dyeing cannot be ignored. Sustainable dyeing methods use eco-friendly materials and processes that minimize waste and pollution while still producing high-quality products. This approach is essential for ensuring long-term success in the fashion industry and protecting the environment.,In conclusion, textile dyeing and processing are essential components of the fashion industry, providing designers with the tools they need to create beautiful and functional garments. As technology continues to advance, it is likely that new and more efficient dyeing techniques will emerge, further enhancing the industry's ability to produce high-quality products while minimizing environmental impact.

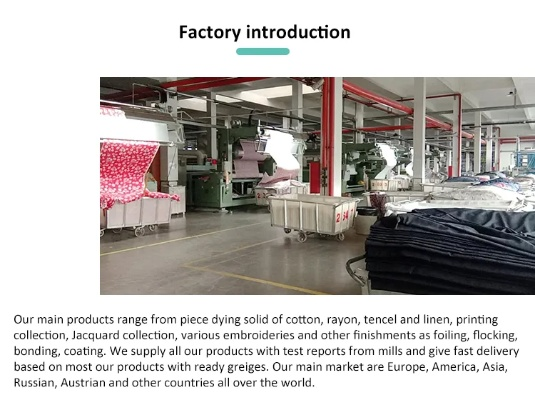

Introduction Textile dyeing and processing are crucial processes in the fashion industry, as they not only enhance the aesthetic appeal of clothing but also contribute to its durability and functionality. This article will discuss the importance of textile dyeing and processing in the fashion industry, including its role in creating unique patterns, color variations, and textures. We will also explore the various techniques used in this process and their impact on the final product. Finally, we will provide an example of a successful textile dyeing and processing case study.

The Importance of Textile Dyeing and Processing Textile dyeing and processing play a vital role in enhancing the overall quality and appeal of clothing. By using different dyes and treatments, designers can create unique patterns, colors, and textures that set their creations apart from others. For example, a designer may choose to use a metallic dye to add a shimmering effect to a piece of clothing, or a satin finish to give it a luxurious feel.

In addition to enhancing the visual appeal of clothing, textile dyeing and processing also improve its durability. By using high-quality materials and proper finishing techniques, designers can ensure that their creations last for years without fading or losing their shape. For instance, a garment made from a soft, breathable fabric with a durable coating applied to the surface can withstand wear and tear while still looking great.

Techniques Used in Textile Dyeing and Processing There are several techniques used in textile dyeing and processing, each with its own advantages and disadvantages. Here are some of the most common methods:

-

Screen Printing: This technique involves printing designs onto a fabric using a mesh screen. It is widely used for producing large quantities of uniformly printed items, such as T-shirts and bags. However, it can be time-consuming and expensive for small runs.

-

Embroidery: Embroidery involves stitching intricate designs onto a fabric using thread. It is often used for creating patterns on clothing, accessories, and home decor. However, it requires specialized equipment and can be time-consuming.

-

Heat Transfer Printing: This technique involves transferring designs from a heat-sensitive material (such as vinyl) to a fabric using heat and pressure. It is popular for creating detailed graphics and logos on clothing, bags, and other items. However, it can be difficult to achieve consistent results and may require additional finishing steps.

-

Stainless Steel Staples: This technique involves applying a thin layer of stainless steel staples to a fabric surface to create a smooth, glossy finish. It is commonly used for creating eye-catching patterns on clothing, bags, and other items. However, it can be time-consuming and costly for small runs.

-

Lamination: Lamination involves applying a protective layer to the surface of a fabric to protect it from wear and tear. It is commonly used for creating waterproof and tear-resistant garments, such as raincoats and jackets. However, it can be time-consuming and costly for small runs.

Example Case Study: Kate Spade New York's "Love" Collection Kate Spade New York is a well-known fashion brand known for its bold and colorful collections. In 2018, the company launched its "Love" collection, which was designed to celebrate love and relationships. To create the collection, the brand collaborated with renowned artist Pablo Picasso to bring his iconic image of a heart into the world of fashion.

To achieve this, Kate Spade New York used a combination of textile dyeing and processing techniques. They first screen printed the design onto a soft, breathable fabric using a mesh screen. Then, they applied a metallic dye to the fabric to add a shimmering effect and highlight the heart shape. Next, they heat-transfer printed the Pablo Picasso image onto the fabric using a heat-sensitive material. Finally, they laminated the fabric to create a protective layer that protected the design from wear and tear.

The resulting "Love" collection featured vibrant colors, bold patterns, and a unique blend of classic and modern design elements. The collection was met with positive reviews and became one of the best-selling collections in Kate Spade New York's history. This case study demonstrates how textile dyeing and processing techniques can be used to create innovative and visually appealing collections that resonate with consumers.

纺织品染整加工概述

纺织品染整加工是利用化学和物理方法对纺织品进行整理和加工的过程,包括染色、印花、整理等多个环节,它不仅提高了纺织品的外观和质量,还推动了纺织行业的发展,在染整加工过程中,各种染料和助剂发挥着重要作用,它们能够赋予纺织品颜色、质地和功能。

染整加工的作用

- 提高纺织品质量:染整加工能够改善纺织品的物理性能,如强度、耐磨性、透气性等,同时还能提高纺织品的耐洗、耐皱等性能。

- 满足市场需求:随着消费者对纺织品品质和功能的要求不断提高,染整加工行业也在不断发展和创新,以满足市场的需求。

- 促进纺织行业可持续发展:染整加工行业的发展离不开环保理念的推广和应用,通过染整加工,可以减少环境污染,提高资源利用效率,推动纺织行业的可持续发展。

染整加工的工艺流程

染整加工的工艺流程主要包括以下几个步骤:原料准备、染色、印花、整理、后处理等,具体流程如下:

- 原料准备:选择合适的原料,如纤维、染料、助剂等。

- 染色:根据纺织品的材质和设计要求,选择合适的染色工艺,如活性染料染色、酸性染料染色等,染色过程中需要控制温度、湿度、染料浓度等参数,以确保染色效果和质量。

- 印花:根据纺织品的图案设计,选择合适的印花工艺,如平网印花、圆网印花等,印花过程中需要控制印花速度、印花图案的清晰度等参数。

- 整理:根据纺织品的需求,进行整理处理,如柔软处理、防皱处理等。

- 后处理:对纺织品进行清洗、干燥、定型等后处理工艺,以提高纺织品的外观和质量。

案例说明

以某知名纺织品品牌为例,其纺织品染整加工过程如下:

- 原料准备:选用高品质的纤维原料,确保染色效果和质量。

- 染色工艺:采用先进的活性染料染色技术,严格控制温度、湿度、染料浓度等参数,确保染色效果达到预期标准。

- 印花工艺:根据纺织品的设计要求,选择合适的印花工艺,如采用数码印花技术,提高印花效率和图案的清晰度。

- 染整加工后处理:对纺织品进行柔软处理和防皱处理,提高其舒适度和耐用性,对纺织品进行清洗和干燥处理,确保其外观和质量达到标准。

纺织品染整加工是纺织行业的重要组成部分,它不仅能够提高纺织品的外观和质量,还推动了纺织行业的发展,在染整加工过程中,各种染料和助剂发挥着重要作用,它们的应用能够满足市场的需求,推动纺织行业的可持续发展,通过案例说明,我们可以看到染整加工技术在不同领域的应用和发展趋势,我们应该重视纺织品染整加工技术的发展和应用,不断提高其技术水平和应用范围。

Articles related to the knowledge points of this article:

Stitching Up Fashion:Crafting the Look with Textile Materials

The Story of Textile Merchandising at 纺芳坊纺织品