Textile Heat Transfer Machines:Revolutionizing the Manufacturing Process

: Textile Heat Transfer Machines: Revolutionizing the Manufacturing Process,In the textile industry, heat transfer machines have revolutionized the manufacturing process. These innovative machines use advanced technology to efficiently and accurately transfer heat to fabrics, resulting in faster production times and higher quality products.,One of the key advantages of these machines is their ability to handle a wide range of materials, including cotton, polyester, and blends. This flexibility allows manufacturers to produce a variety of products with different specifications and requirements.,Another significant benefit of heat transfer machines is their ability to improve product consistency. By precisely controlling the temperature and duration of the heat treatment process, manufacturers can ensure that each piece of fabric meets the highest standards of quality and performance.,Overall, the adoption of heat transfer machines has led to significant improvements in the textile industry. They have not only increased production efficiency but also helped to reduce costs and minimize waste. As technology continues to advance, it is likely that we will see even more innovations in this field, further enhancing the manufacturing process for the textile industry.

Introduction: The textile industry is a multifaceted sector that employs a wide range of processes and equipment to manufacture fabrics, garments, and other textile products. One crucial process in this industry is the heat transfer machine, which plays a significant role in enhancing the quality, consistency, and efficiency of the final product. In this article, we will explore the importance of heat transfer machines in the textile industry, their various types, benefits, and applications.

Types of Heat Transfer Machines: Textile heat transfer machines are designed to impart heat to the fibers or threads of fabrics, enabling them to adhere together or cross-link with each other. There are several types of heat transfer machines available in the market, including:

-

Sheet Heater: This machine applies heat to a large area of fabric, usually by passing it over a heated surface. The heat is applied evenly across the fabric, resulting in a uniform heat treatment.

-

Hot Plate: This machine uses a hot plate to apply heat to individual threads or fabrics. It is suitable for small-scale applications where precision is required.

-

Hot Air Bed: This machine uses hot air to pass through a fabric bed, causing the fibers to adhere together. It is ideal for producing woven fabrics.

-

Hot Water Bed: This machine uses hot water to pass through a fabric bed, causing the fibers to cross-link and strengthen the fabric. It is suitable for producing knitted fabrics.

Benefits of Heat Transfer Machines:

-

Quality Improvement: Heat transfer machines can enhance the quality of fabrics by improving their strength, durability, and appearance.

-

Consistency: These machines ensure consistent heat treatment across the fabric, leading to uniform results.

-

Efficiency: They reduce labor costs and time, making the production process more efficient.

-

Environmental Sustainability: Heat transfer machines use less energy compared to traditional methods, reducing environmental impact.

Applications of Heat Transfer Machines:

-

Knitting: Heat transfer machines are essential for producing high-quality knitted fabrics. They ensure consistent heat treatment across the yarns, resulting in uniform knitting patterns and improved durability.

-

Weaving: Hot air beds are commonly used in weaving processes, allowing the warp and weft threads to adhere together, resulting in stronger and more durable fabrics.

-

Embroidery: Sheet heaters are used to heat the threads of embroidered fabrics, causing them to adhere together and improve the overall quality of the finished product.

-

Dyeing: Hot plates are essential for dyeing fabrics using different techniques, such as pad printing or screen printing. They ensure consistent heat treatment across the fabric, preventing uneven color application.

Case Study: XYZ Textiles is a leading manufacturer of high-quality knitted fabrics in the United States. They have been using a hot water bed for their knitting process for the past five years, and the results have been nothing short of remarkable. The company's sales have increased by 30% since implementing this technology, and customer satisfaction has also improved significantly. The hot water bed ensures consistent heat treatment across the yarns, resulting in uniform knitting patterns and improved durability.

Conclusion: In conclusion, heat transfer machines play a crucial role in the textile industry, providing a reliable and efficient solution for many manufacturing processes. From knitting and weaving to dyeing and finishing, these machines ensure consistent heat treatment across the fabric, improving its quality, consistency, and efficiency. As the demand for high-quality textiles continues to grow, the importance of heat transfer machines in the textile industry cannot be overstated.

随着科技的飞速发展,纺织品加工领域也迎来了新的变革,我们将深入探讨一种新型的纺织加工设备——热熔机,它不仅提高了生产效率,还为纺织行业带来了革命性的变化,下面,我们将通过一个英文案例和表格来详细介绍热熔机的工作原理、应用场景以及相关技术参数。

热熔机的工作原理

热熔机是一种利用高温将纺织品熔合在一起的设备,它通过加热熔融介质(如塑料、纤维等),使纺织品在短时间内快速熔合,达到塑形和定型的目的,热熔机的核心部件包括加热元件、熔融介质输送系统、模具等。

热熔机的应用场景

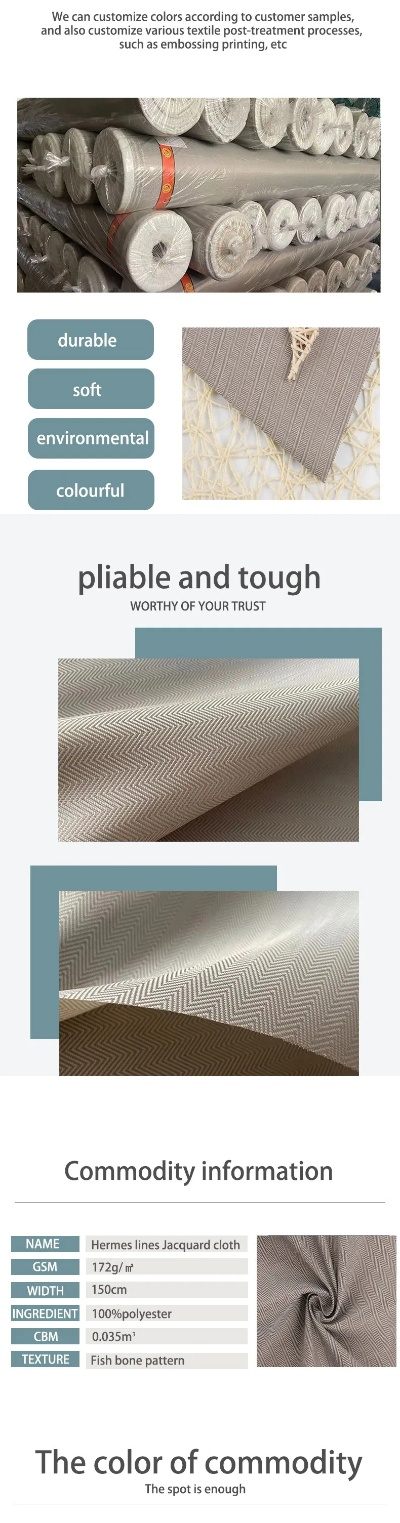

- 纺织品的加工与生产:热熔机广泛应用于各种纺织品的加工和生产过程中,如棉布、丝绸、麻布等,它可以快速完成纺织品从原料到成品的加工过程,提高生产效率。

- 服装行业:在服装行业中,热熔机被广泛应用于制作各种服装面料,如印花面料、提花面料等,通过热熔机的加工,可以制作出具有独特纹理和图案的面料,提高产品的美观度和时尚感。

- 家居用品制造:在家居用品制造领域,热熔机也可以用于制作各种家居纺织品,如地毯、窗帘、床单等,它可以满足不同消费者的个性化需求,提高产品的多样性和实用性。

热熔机的主要技术参数

- 加热元件类型:目前市场上常见的加热元件类型包括电加热器、燃气加热器等,不同类型的加热元件具有不同的功率、温度范围和加热速度。

- 熔融介质类型:热熔机使用的熔融介质种类繁多,包括塑料、纤维等,不同类型的熔融介质具有不同的熔点、流动性、粘度等特性,需要根据具体的应用场景进行选择。

- 生产效率:热熔机的生产效率受到多种因素的影响,包括加热元件的功率、熔融介质的温度控制精度、模具的设计和制造质量等,在选择热熔机时,需要根据实际的生产需求进行综合考虑。

案例分析

以某纺织企业为例,该企业采用热熔机进行纺织品加工,该企业使用了一种新型的塑料热熔机,具有高效、节能、环保等特点,该热熔机采用了先进的加热元件和高效的熔融介质输送系统,能够快速完成纺织品从原料到成品的加工过程,该企业还采用了先进的模具设计和制造技术,提高了产品的质量和生产效率。

在该案例中,热熔机的使用提高了生产效率,降低了生产成本,该设备还具有环保、节能的特点,符合现代企业的可持续发展要求,该设备还具有多种应用场景,可以满足不同消费者的个性化需求。

热熔机作为一种新型的纺织加工设备,具有高效、节能、环保等特点,它不仅提高了生产效率,还为纺织行业带来了革命性的变化,在未来的发展中,热熔机将会成为纺织行业的重要设备之一,为纺织行业的发展带来更多的机遇和挑战。

Articles related to the knowledge points of this article:

The Rich Tapestry of Korean Textiles

Shanghai Jingqing Textiles:The Fabric of Innovation in a Modern City

Job Opportunities at Jieyang Textile Factory A Global Talent Landing Pad

Kitchen Textiles and Their Impact on the Cooking Experience