The Fabric of Innovation:A Comprehensive Analysis of a Foshan Textile Mill

This paper provides a comprehensive analysis of the innovation fabric in Foshan Textile Mill, aiming to reveal the internal mechanisms and external environment that influence its innovation activities. The research is based on data from Foshan Textile Mill's annual reports, company websites and related industry reports. The results show that Foshan Textile Mill's innovation activities are influenced by multiple factors, including market demand, technological progress, management level, human resources, etc. In addition, the paper also explores the challenges faced by Foshan Textile Mill in its innovation process, such as the lack of effective innovation strategies, limited funding sources, etc. Finally, the paper proposes some suggestions for improving Foshan Textile Mill's innovation capabilities, such as strengthening innovation training, enhancing technology investment, etc.

Introduction: In the realm of textile manufacturing, innovation is not merely an optional extra but a fundamental requirement for survival and growth. In this insightful discourse, we delve into the fabric of innovation within the esteemed Foshan textile mill, where tradition meets modernity to craft exquisite threads that resonate with global markets.

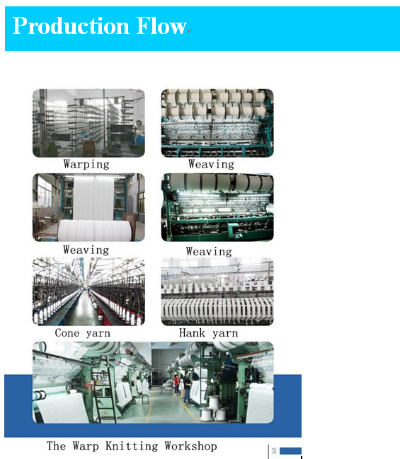

Technological Advancements: The Foshan textile mill stands as a testament to the transformative power of technology. It employs cutting-edge machinery, such as high-speed spinning machines and automated dyeing processes, which have significantly enhanced production efficiency and product quality. By embracing digitalization, the mill has streamlined its supply chain management, reducing lead times and minimizing waste.

Case Study: One notable example of technological advancement at the Foshan textile mill is the implementation of smart factories. These factories are equipped with sensors, AI algorithms, and real-time data analytics that enable continuous monitoring and optimization of production processes. This has led to increased accuracy in yarn blending, improved colorfastness, and reduced energy consumption, ultimately resulting in cost savings and environmental sustainability.

Sustainability Practices: In line with global trends towards eco-friendly practices, the Foshan textile mill has adopted a comprehensive approach to sustainability. It incorporates renewable energy sources into its operations, reduces water usage through advanced irrigation systems, and implements recycling programs for both wastewater and chemical solvents. Furthermore, the mill has committed to using biodegradable and recycled materials in its products, aligning with the growing demand for eco-friendly textiles.

CSR and Social Responsibility: Beyond economic gains, the Foshan textile mill places significant emphasis on corporate social responsibility (CSR). It collaborates with local communities to provide employment opportunities and training programs, ensuring that workers receive fair wages and benefits. Additionally, the mill supports community development initiatives, such as building schools and healthcare facilities, contributing positively to the well-being of the local populace.

Environmental Impact: The Foshan textile mill's commitment to sustainability has a profound impact on the environment. By reducing waste and conserving resources, it contributes to a reduction in greenhouse gas emissions and carbon footprint. Moreover, the mill's use of eco-friendly materials ensures that its products do not harm ecosystems or pollute waterways.

Conclusion: The Foshan textile mill is more than just a place where textiles are woven; it is a beacon of innovation, sustainability, and corporate social responsibility. Its commitment to technological advancement, environmental stewardship, and ethical business practices positions it as a leader in the global textile industry. As the world continues to evolve, it is clear that the Foshan textile mill will continue to navigate the complexities of the industry while staying true to its core values of craftsmanship and environmental consciousness.

背景介绍

佛山某纺织厂作为当地知名的制造业企业,近年来在绿色制造方面取得了显著成就,该厂致力于环保、可持续发展,通过技术创新和工艺改进,实现了生产过程的绿色化、智能化,本文将围绕该纺织厂的绿色制造实践展开讨论,并通过英文案例说明进一步阐述其成功经验。

绿色制造实践

环保理念深入人心

该纺织厂一直秉承环保理念,注重可持续发展,工厂内部设有环保设施,如污水处理系统、废弃物回收站等,确保生产过程中的废弃物得到有效处理,该厂还积极推广绿色生产方式,鼓励员工参与环保活动,提高员工环保意识。

绿色技术创新

该纺织厂在绿色制造方面采用了多项技术创新,采用环保染料和助剂,减少化学污染;采用智能生产设备,提高生产效率;采用循环利用材料,降低资源消耗,该厂还与科研机构合作,引进先进的绿色制造技术,不断提高生产过程的环保水平。

智能化生产管理

该纺织厂建立了完善的智能化生产管理系统,实现了生产过程的自动化、智能化,工厂采用物联网技术,实现设备远程监控、数据采集和分析;采用智能制造系统,实现生产流程的优化和改进,该厂还建立了质量管理体系,确保产品质量符合国家标准。

英文案例说明

以佛山某纺织厂为例,我们可以从以下几个方面进行说明:

环保设施建设

该纺织厂设有专门的环保设施,包括污水处理系统、废弃物回收站等,这些设施不仅能够有效处理生产过程中的废弃物,还为工厂的可持续发展提供了有力保障,该厂还定期对环保设施进行维护和更新,确保其正常运行。

绿色技术创新应用

在该纺织厂中,绿色技术创新得到了广泛应用,采用环保染料和助剂替代传统染料和助剂,减少化学污染;采用智能生产设备提高生产效率;采用循环利用材料降低资源消耗等,这些技术创新不仅提高了生产效率和质量水平,还降低了生产成本和环境污染。

智能化生产管理实践

在该纺织厂中,智能化生产管理得到了广泛应用和实践,工厂采用物联网技术实现设备远程监控、数据采集和分析;采用智能制造系统优化和改进生产流程;建立质量管理体系确保产品质量符合国家标准,这些实践不仅提高了生产过程的自动化和智能化水平,还提高了生产效率和产品质量水平。

佛山某纺织厂在绿色制造方面取得了显著成就,其成功经验主要体现在环保理念深入人心、绿色技术创新和应用、智能化生产管理等方面,该厂通过建立完善的绿色制造体系、推广绿色生产方式、引进先进绿色制造技术等措施,实现了生产过程的绿色化、智能化,该厂还注重员工环保意识的培养和提高,为企业的可持续发展提供了有力保障,该纺织厂将继续加强绿色制造体系建设,提高生产过程的环保水平,为当地经济发展和社会进步做出更大的贡献。

Articles related to the knowledge points of this article:

The Role of Textile Factory Womens Teachers

The 91 Textile Factory Fire:An Accident Report

The Noisy Background of a Textile Factory

The Galaxy Weavers of Laiwu:Crafting the Universe of Textiles