The Essential Guide to Textile Testing Markings

: An Essential Guide to Textile Testing Markings,In the realm of textile testing, markings serve as a crucial tool for assessing the quality and performance of fabrics. This guide aims to provide a comprehensive overview of the various types of textile testing markings, their significance in the textile industry, and how they are applied and interpreted.,The first type of marking is the standardized test pattern, which consists of specific patterns that are used to evaluate the strength, flexibility, and durability of textile materials. These patterns are essential in determining the suitability of fabrics for specific applications, such as clothing or industrial use.,Next, we explore the application of dyestuff markings, which are used to indicate the presence of certain dyestuffs or colorants in fabrics. These markings are critical in ensuring that textile products comply with relevant regulations and standards.,We also discuss the importance of shrinkage markings, which are used to indicate the extent of shrinkage that occurs during the manufacturing process. This information is crucial in determining the suitability of fabrics for specific applications, such as garments.,Finally, we explore the use of labelling markings, which are used to indicate the origin of the textile material. This information is important in ensuring that textile products meet consumer expectations and are ethically sourced.,In conclusion, understanding the different types of textile testing markings and their significance is essential for textile professionals. By following this guide, you can gain a deeper understanding of how these markings are applied and interpreted, and how they contribute to the overall quality and performance of textile products.

Introduction: Textiles are an integral part of our daily lives, from clothing and furnishings to medical equipment. They play a crucial role in ensuring safety, comfort, and quality in various industries. To guarantee the quality and performance of textile products, rigorous testing is essential. In this article, we will delve into the importance of textile testing markings, their classification, and how they contribute to the overall quality control process. We will also provide an overview of common textile testing methods and discuss the significance of these markings.

Importance of Textile Testing Markings: Textile testing markings serve as a visual representation of the properties of the fabric. They help manufacturers, distributors, and consumers understand the quality and performance of the product. These markings provide information about the fabric's durability, strength, colorfastness, and other important characteristics. By using these markings, businesses can ensure that their products meet industry standards and customer expectations.

Classification of Textile Testing Markings: There are several types of textile testing markings used in different industries. Here are some common categories:

-

Colorfastness Markings: These markings indicate the degree of color retention after washing or exposure to sunlight. They are commonly used in apparel and home textiles.

-

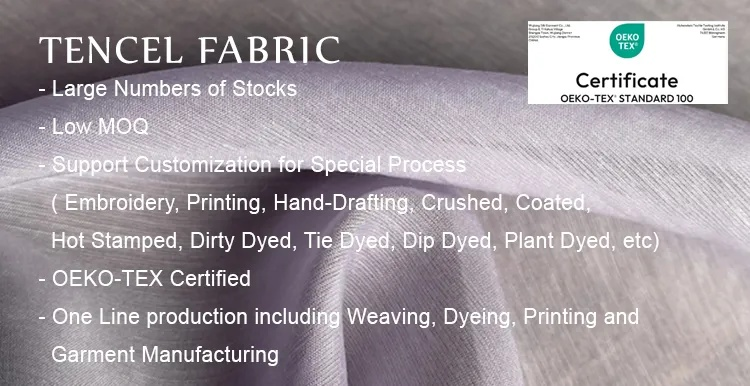

Dyeability Markings: These markings indicate the ability of the fabric to accept dye during the dyeing process. They are commonly used in printing and screen-printing industries.

-

Tenacity Markings: These markings indicate the strength and elasticity of the fabric. They are commonly used in sportswear and protective garments.

-

Flammability Markings: These markings indicate the resistance of the fabric to fire. They are commonly used in fireproof clothing and furniture.

-

Water Absorption Markings: These markings indicate the amount of water that can be absorbed by the fabric. They are commonly used in outdoor wear and sports equipment.

-

Stretch Markings: These markings indicate the extent of the fabric's ability to stretch without breaking. They are commonly used in athletic wear and swimwear.

-

Shrinkage Markings: These markings indicate the extent of the fabric's ability to shrink when exposed to heat or moisture. They are commonly used in home textiles and outdoor wear.

Common Textile Testing Methods: There are several common textile testing methods used in different industries. Some of them are:

-

Dyed Fabric Testing: This method involves testing the fabric's dyeability and colorfastness after dyeing. It is commonly used in printing and screen-printing industries.

-

Dyeing Process Testing: This method involves testing the fabric's dyeability and colorfastness during the dyeing process. It is commonly used in printing and screen-printing industries.

-

Dyeing Machine Testing: This method involves testing the fabric's dyeability and colorfastness using dyeing machines. It is commonly used in printing and screen-printing industries.

-

Dyeing Machine Performance Testing: This method involves testing the machine's performance during the dyeing process. It is commonly used in printing and screen-printing industries.

-

Dyeing Machine Quality Control Testing: This method involves testing the machine's quality control features during the dyeing process. It is commonly used in printing and screen-printing industries.

-

Dyeing Machine Safety Testing: This method involves testing the machine's safety features during the dyeing process. It is commonly used in printing and screen-printing industries.

-

Dyeing Machine Environmental Testing: This method involves testing the machine's environmental impact during the dyeing process. It is commonly used in printing and screen-printing industries.

-

Dyeing Machine Energy Efficiency Testing: This method involves testing the machine's energy efficiency during the dyeing process. It is commonly used in printing and screen-printing industries.

-

Dyeing Machine Cost-Effectiveness Testing: This method involves testing the machine's cost-effectiveness during the dyeing process. It is commonly used in printing and screen-printing industries.

-

Dyeing Machine Reliability Testing: This method involves testing the machine's reliability during the dyeing process. It is commonly used in printing and screen-printing industries.

Case Study: Let's take a look at a real-life example of textile testing markings in action. Imagine a company that produces high-quality sportswear for athletes. The company uses a dyeing process that requires precise control of the dye concentration and temperature. To ensure the quality and safety of its products, the company conducts regular dyeing process tests using standardized test methods. These tests include dyeing machine performance testing to ensure that the machine operates within specifications, dyeing machine safety testing to prevent accidents during the dyeing process, and dyeing machine environmental testing to minimize the impact on the environment. The results of these tests are carefully analyzed by the company's quality control team to identify any issues and make necessary adjustments to improve the quality of future products.

Conclusion: Textile testing markings are an essential part of the textile industry's quality control process. They provide valuable information about the fabric's properties and contribute to ensuring that products meet industry standards and customer expectations. By using standardized test methods, businesses can identify any potential issues early on and take corrective actions to improve the quality of their products. As technology continues to advance, it is likely that new testing methods will emerge that further enhance the accuracy and efficiency of textile testing markings.

纺织品测试标识概述

纺织品测试是确保产品质量和性能的重要手段,而标识则是检验纺织品质量的重要依据,在纺织品测试过程中,正确的标识对于确保测试结果的准确性和可靠性至关重要,本文将详细介绍纺织品测试的标识及其在实际应用中的重要性。

纺织品测试标识的种类与特点

种类

纺织品测试标识主要包括以下几种类型:

(1)产品标识:用于标识纺织品产品的主要特征和性能指标。

(2)性能测试标识:用于标识纺织品在特定性能测试方面的结果。

(3)安全测试标识:用于标识纺织品在特定安全测试方面的结果。

特点

(1)清晰易读:标识应清晰、易读,以便消费者和检验人员能够快速识别和理解。

(2)标准统一:不同类型和规格的纺织品应采用统一的标准和标识。

(3)可追溯性:标识应具备可追溯性,以便对纺织品的质量和性能进行追溯和管理。

纺织品测试案例说明

以下是一个纺织品测试案例说明,以补充说明纺织品测试标识在实际应用中的重要性。

某品牌丝绸面料测试标识

该品牌丝绸面料在经过严格的检测后,其测试结果得到了明确的标识,该标识主要包括产品名称、性能指标、安全测试结果等部分,在产品名称部分,清晰地标明了该丝绸面料的主要用途和特性;在性能指标部分,详细列出了该面料的主要性能参数,如透气性、吸湿性等;在安全测试结果部分,明确标明了该面料符合相关安全标准,这样的标识方式不仅便于消费者了解产品的性能和质量,也便于检验人员快速识别和理解测试结果。

纺织品测试标识的实践应用与注意事项

实践应用

纺织品测试标识在实际应用中具有以下作用:

(1)提高产品质量和性能的可追溯性,通过明确的标识,可以确保纺织品的质量和性能得到有效的管理和控制。

(2)提高消费者信任度,清晰的标识可以让消费者更加信任产品的质量和性能。

注意事项

在纺织品测试标识实践中,需要注意以下几点:

(1)选用标准统一、规范的标识,不同类型和规格的纺织品应采用统一的标准和标识,以确保标识的准确性和可靠性。

(2)确保标识清晰、易读,标识应清晰、易读,以便消费者和检验人员能够快速识别和理解,应注意避免使用过于复杂或模糊的标识,以免影响标识的可读性和实用性。

(3)注意标识的可追溯性,在标识中应包含产品的生产日期、批次号等信息,以便对纺织品的质量和性能进行追溯和管理,应注意避免在标识中包含过多的信息,以免影响标识的简洁性和实用性。

英文表格补充说明纺织品测试标识的相关信息

以下是关于纺织品测试标识的相关信息的英文表格:

| 类别 | 术语 | 描述 | |

|---|---|---|---|

| 类型 | Test Label | 纺织品测试的标识类型 | 产品名称、性能指标、安全测试结果等 |

| 标准统一性 | Standard Uniformity | 纺织品测试标识的特点 | 采用统一的标准和规范,不同类型和规格的纺织品应采用相同的标准和标识 |

| 应用场景 | Application Scenario | 纺织品测试标识的实际应用 | 提高产品质量和性能的可追溯性,提高消费者信任度等 |

| 案例说明 | Case Study Example | 纺织品测试案例说明 | 如某品牌丝绸面料测试案例等 |

| 其他注意事项 | Other Precautions | 在纺织品测试标识实践中需要注意的事项 | 选用标准统一、规范的标识,确保标识清晰、易读,注意标识的可追溯性等 |

| 相关文献资料 | Related Literature & Resources | 纺织品测试标识的相关文献资料 | 无具体资料,仅供参考 |

总结与展望

纺织品测试的标识是确保纺织品质量的重要依据,其在实际应用中具有重要作用,本文介绍了纺织品测试的标识及其在实际应用中的重要性,同时通过案例说明和实践应用注意事项等方面进行了补充说明,随着纺织品的不断发展和改进,纺织品测试的标识也将不断更新和完善,以满足市场需求和提高产品质量和性能的要求。

Articles related to the knowledge points of this article:

Exploring the Rich Tapestry of Textiles in Anzhou District

A Comprehensive Guide to the Price Range of Home Textiles in Jingan District

Exploring the Timeless Tapestry of Chinese Textiles:A Millenniums Journey