The Art of Fabricating Services for Textile Mills

: The Art of Fabricating Services for Textile Mills,Abstract:,This paper discusses the importance of providing customized services to textile mills. It highlights the need for a comprehensive understanding of their specific needs and how this knowledge can be leveraged to tailor solutions that meet their unique requirements. The paper also explores the benefits of offering tailored services, including increased efficiency, improved quality, and reduced costs. Finally, it provides insights into the challenges faced by textile mills in finding reliable service providers and offers strategies for overcoming these challenges. Overall, the paper emphasizes the value of providing customized services to textile mills and the importance of understanding their specific needs to deliver exceptional results.

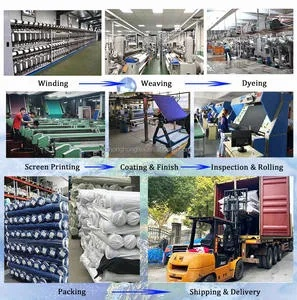

In the vast world of textile manufacturing, the concept of 'fabricating services' is not just a buzzword; it's a cornerstone of business operations. At the heart of this process lies the textile mill, where the raw materials are transformed into high-quality fabrics that meet the demands of various industries. To succeed in this competitive landscape, textile mills must employ a comprehensive approach to fabrication services, one that involves careful planning, meticulous execution, and continuous improvement. In this article, we will explore the key aspects of fabrication services for textile mills and provide an example to illustrate best practices.

At the outset, it's essential for textile mills to understand their customer base and tailor their fabrication services accordingly. By conducting market research and analyzing customer needs, mills can identify areas where they can offer specialized fabrication services. For instance, if a textile mill specializes in making high-quality cotton t-shirts, it could offer customization options like different colors, sizes, and designs. This not only enhances customer satisfaction but also helps the mill stand out in a crowded market.

Once the fabrication services have been defined, the next step is to develop a detailed plan that outlines the steps required to produce each product. This includes sourcing the right raw materials, selecting the appropriate machinery, and setting up the production schedule. It's important to establish clear communication channels between the mill and its partners, as well as regular check-ins to ensure that everything is running smoothly.

One of the most challenging aspects of fabrication services is ensuring consistency and quality across all products. To achieve this, textile mills must invest in advanced technology and equipment that can handle a wide range of fabrications. For example, using computer-controlled machines allows for precise measurements and consistent stitching, resulting in higher-quality products. Additionally, implementing quality control measures such as inspections and testing before and after production can help catch any issues early on and prevent defects from reaching the customer.

Another critical aspect of fabrication services is flexibility. With changing market trends and customer preferences, textile mills must be able to adapt quickly to new demands. This means investing in agile production systems that can switch between different fabrication processes seamlessly. For instance, if demand for a particular fabrication suddenly spikes, the mill can quickly switch to producing it at full capacity without disrupting other processes.

To further illustrate best practices, let's look at a case study of a textile mill that successfully implemented a comprehensive fabrication services strategy. The mill had been struggling to meet customer demands due to outdated technology and inconsistent quality levels. However, through strategic planning and investment in new equipment, the mill was able to streamline its processes and improve efficiency.

The mill established clear goals for each fabrication service, including reducing lead times, increasing productivity, and maintaining high-quality standards. They also developed a training program for their staff to ensure that everyone was equipped with the knowledge and skills needed to operate the new equipment effectively. This not only boosted productivity but also improved employee morale and job satisfaction.

The mill also implemented a feedback system that allowed customers to provide input on their experiences with the fabrication services. This feedback was then used to make ongoing improvements to the process, ensuring that the mill remained competitive and responsive to changing market conditions.

In conclusion, fabrication services are a crucial component of any textile mill's success. By carefully defining customer needs, developing a detailed plan, investing in advanced technology and equipment, and implementing flexible production systems, textile mills can deliver high-quality products that meet the evolving demands of their customers. The case study provided highlights how these strategies can be applied to improve efficiency, reduce costs, and enhance customer satisfaction. As the industry continues to evolve, textile mills that adopt a proactive approach to fabrication services will be better positioned to thrive in a competitive marketplace.

开场白

大家好,今天我们将探讨一个纺织厂如何成功承接包活业务的话题,在接下来的内容中,我们将通过一个具体的案例来详细说明。

案例介绍

假设某纺织厂近期接到了多个包活订单,以下是相关案例的简要说明:

-

订单背景 该纺织厂近期面临市场需求增加,需要承接更多的包活业务,订单涉及的产品种类多样,包括但不限于各种面料、服装辅料等。

-

订单细节 订单的具体细节包括所需产品数量、质量标准、交货时间等,订单的具体内容涉及生产某种特定款式服装的面料和辅料。

案例分析

为了更好地理解这个案例,我们可以从以下几个方面进行分析:

-

采购策略 纺织厂在接到订单后,首先进行了全面的市场调研,了解市场需求和竞争情况,根据市场需求和自身产能情况,制定了一套合理的采购策略。

-

生产计划与安排 纺织厂根据订单要求,制定了详细的生产计划,并安排了相应的生产资源,在生产过程中,纺织厂注重质量控制和成本控制,确保产品符合质量标准。

-

质量控制与检验 纺织厂在生产过程中注重产品质量控制,采用了严格的质量检验流程,为了确保产品质量的一致性,还与供应商建立了质量保证体系。

-

包装与运输方案 纺织厂针对包活业务的特点,制定了相应的包装与运输方案,采用了适合产品的包装材料和运输方式,确保产品能够安全、快速地送达客户手中。

英文案例说明

以下是一个英文案例表格,用于进一步说明纺织厂包活业务的细节:

纺织厂包活业务案例说明

| 环节 | 具体描述 | 相关数据 |

|---|---|---|

| 订单背景 | 新增市场需求、订单涉及产品种类多样 | |

| 采购策略 | 市场调研、产能评估、采购策略制定 | |

| 生产计划与安排 | 根据订单要求制定详细的生产计划、安排生产资源 | |

| 质量控制与检验 | 采用严格的质量检验流程、与供应商建立质量保证体系 | |

| 包装与运输方案 | 采用适合产品的包装材料和运输方式、确保产品安全快速送达客户手中 | |

| 通过上述分析可以看出,纺织厂在承接包活业务方面表现出色,不仅满足了市场需求,还注重产品质量和成本控制。 |

总结与展望

通过上述案例分析,我们可以看到纺织厂在承接包活业务方面表现出色,他们根据市场需求和自身产能情况,制定了一套合理的采购策略和生产计划,他们注重质量控制和成本控制,确保产品符合质量标准,在包装与运输方面,他们也采取了相应的措施,确保产品能够安全、快速地送达客户手中,纺织厂可以进一步优化采购策略和生产计划,提高产品质量和竞争力,他们也可以加强与供应商的合作,建立更加完善的质量保证体系,他们还可以关注行业动态和市场变化,及时调整生产计划和销售策略,以适应市场需求的变化。

Articles related to the knowledge points of this article:

The Ease of a Textile Factory Life

The Story of QuanMei Textile Factory