The Art of Textile Temperature Testing:A Comprehensive Guide

: The Art of Textile Temperature Testing: A Comprehensive Guide,Abstract: This comprehensive guide provides a detailed overview of the art and science of textile temperature testing. It covers various methods, including hot-air, cold-air, and infrared testing, as well as their applications in different industries such as fashion, sportswear, and industrial fabrics. The guide also discusses the importance of temperature testing in ensuring product quality and meeting regulatory requirements. By following this guide, readers will gain a deeper understanding of the technical aspects of textile temperature testing and how to implement it effectively in their own work.

In the world of textiles, temperature is not just a factor to consider; it's a critical component that can impact the quality and longevity of our garments. From the delicate fabrics of a designer gown to the sturdy denim jeans, every step in the production process demands precise control over temperature conditions. That's where textile temperature testing comes into play. This guide will walk you through the various methods used to measure and regulate the temperature of textile materials, from standard laboratory tests to practical applications in industrial settings.

Let's start with the basics. Textile temperature testing is essential for ensuring that the fabrics meet the required standards and specifications set by regulatory bodies such as the European Standard (EN) 17582, ASTM D3849, or other local industry-specific guidelines. It involves measuring the temperature at which a material reaches its equilibrium state—known as the "thermal equilibrium temperature" or "TET."

The TET is a crucial parameter because it determines how well the fabric will retain its shape and maintain its structural integrity when subjected to various environmental conditions. For example, if a shirt material has a TET of 60°C, it means that the fabric will remain stable and comfortable even when worn in hot environments. Conversely, if the TET is higher than 60°C, the fabric may lose its shape or feel uncomfortable in warm weather.

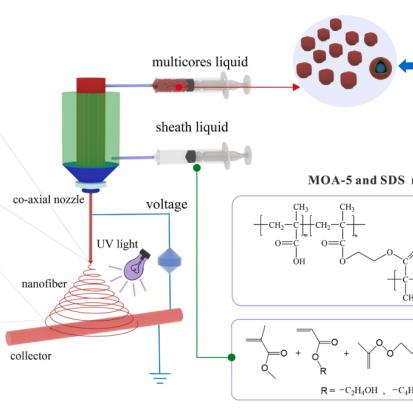

To test for TET, we use a variety of methods, including:

| Method | Description |

|---|---|

| Static Thermogravimetric Analysis (STTA) | In this method, a sample of the textile material is heated gradually until it reaches its TET. The temperature at which this occurs is recorded. |

| Dynamic Thermogravimetric Analysis (DTGA) | This method measures the weight loss of the textile material as it is heated. By plotting the weight loss against temperature, we can determine the TET. |

| Differential Scanning Calorimetry (DSC) | This technique uses a heat source to heat the sample and measure the resulting change in heat energy. By analyzing the heat flow curve, we can determine the TET. |

| Thermogravimetric Analysis (TGA) | In this method, a sample is heated at constant rate until it reaches its TET. The mass remaining after the heating is recorded. |

Now let's dive into some practical examples to illustrate how these techniques are applied in real-world scenarios.

Case Study: Textile Material for Military Uniforms

Imagine a company producing military uniforms for soldiers deployed around the world. They require textile materials that are both durable and breathable to keep soldiers comfortable during extended deployments. To ensure their uniforms meet the rigorous standards set by military regulations, they conduct a series of temperature tests on different fabric samples.

Using STTA, they determine the TET for each fabric sample and select the one with the highest stability at 60°C. Then, they perform DSC and TGA tests to verify that the selected fabric meets all thermal performance requirements. Finally, they subject the fabric to various stress tests to simulate the wear and tear of actual military use.

Case Study: Textile Material for High-End Fashion Shows

For high-end fashion shows, designers often rely on advanced textile technology to create unique and luxurious garments. One such company designs a dress made entirely of silk. To ensure its durability and comfort, they conduct extensive temperature testing on the silk fabric before finalizing the design.

They use DSC to determine the TET for the silk fabric and select the one closest to 30°C. Then, they perform STTA and DSC tests on a small sample of the silk fabric to validate its performance under different temperatures and humidity conditions. Additionally, they conduct a skin contact test to ensure that the fabric does not cause any discomfort or irritation to the wearer's skin.

Conclusion: The Art of Textile Temperature Testing

Textile temperature testing is more than just a technical process; it's an art form that ensures the quality and safety of our clothes. By understanding the different methods and techniques available, we can better tailor our textile materials to meet specific needs and expectations. Whether it's for military uniforms or high-end fashion shows, accurate temperature testing is crucial to achieving success in our industry. So let's embrace the art of textile temperature testing and continue pushing the boundaries of what's possible in the world of textiles!

大家好,今天我们将探讨纺织品温度测试的重要性及其方法,纺织品作为日常生活中的重要组成部分,其质量直接关系到穿着舒适度和安全性,对纺织品进行准确的温度测试是确保其性能和质量的关键步骤。

纺织品温度测试方法

实验室测试方法

实验室温度测试是纺织品温度测试的主要方法,通常采用标准温度计进行测量,同时使用专业的纺织品测试仪器进行数据采集和分析,具体步骤包括准备样品、设置测试环境、进行温度测量等,在测试过程中,需要注意保持测试环境的稳定性和准确性,以确保测试结果的准确性。

现场快速测试方法

现场快速测试方法适用于紧急情况下,如纺织品在生产现场或消费者购买后的紧急检测,可以采用便携式温度计进行现场快速测试,具体步骤包括将便携式温度计放置在待测纺织品上,快速读取数据,需要注意的是,现场快速测试可能存在一定的误差和局限性,因此需要结合实验室测试结果进行综合评估。

案例分析

纺织品温度测试的重要性

某品牌服装面料在生产过程中需要进行严格的温度控制,为了确保产品质量和穿着舒适度,该品牌采用了纺织品温度测试方法进行质量控制,通过实验室和现场快速测试相结合的方式,对每一批次的纺织品进行温度检测,确保产品质量符合标准。

纺织品温度测试的具体步骤

在实验室温度测试中,首先准备样品,选择合适的温度计进行测量,然后设置测试环境,确保环境稳定性和准确性,接下来进行数据采集和分析,得出准确的温度数据,在现场快速测试中,可以采用便携式温度计进行快速检测,同时结合其他检测手段进行综合评估。

英文表格补充说明

以下是纺织品温度测试方法的英文表格补充说明:

| 测试项目 | 实验室测试方法 | 现场快速测试方法 | 注意事项 |

|---|---|---|---|

| 样品准备 | 使用标准温度计测量样品 | 使用便携式温度计进行现场快速测试 | 确保样品准备充分、准确无误 |

| 环境设置 | 设置稳定的测试环境 | 注意保持环境稳定性和准确性 | 确保测试环境的稳定性和准确性 |

| 温度测量 | 使用专业的纺织品测试仪器进行数据采集和分析 | 采用便携式温度计进行数据读取 | 注意读取数据的准确性 |

| 结果分析 | 综合实验室和现场测试结果进行评估 | 综合评估结果与标准进行比较 | 需要结合其他检测手段进行综合评估 |

纺织品温度测试是确保纺织品性能和质量的关键步骤,通过实验室和现场快速测试相结合的方式,可以更好地满足纺织品质量控制的需要,在实际应用中,还需要结合其他检测手段进行综合评估,以确保纺织品的质量符合标准。

Articles related to the knowledge points of this article:

Consumer Complaints about Textile Products in Wuxi A Case Study and Analysis

The Art of Interior Textiles:Crafting a Masterpiece in the Canvas

Strategies for the Implementation of Medical Textiles:A Comprehensive Guide

The Multifaceted World of Navier Textiles:A Comprehensive Guide

The Pinnacle of Fashion at Nantong A Closer Look at Nanton Power-Up Textiles

The State-of-the-Art in Nanning Textile Inspection:A Comprehensive Analysis