The Comprehensive Purchase Process for Textile Mills

This study explores the comprehensive purchasing process for textile mills, focusing on the key stages involved in sourcing and acquiring raw materials, as well as the strategies employed to ensure the efficient procurement of high-quality products. By conducting a thorough analysis of market trends, supplier selection criteria, and logistical considerations, we aim to provide valuable insights into how textile mills can optimize their purchasing activities to meet operational and financial goals. This includes exploring the use of advanced technology in inventory management and supply chain optimization, and identifying areas for improvement within current purchasing processes. The findings highlight the importance of establishing long-term partnerships with reputable suppliers and implementing effective risk management strategies to safeguard against potential disruptions in supply chains. Ultimately, our research contributes to the ongoing debate on the future of procurement practices in the global textile industry, offering practical recommendations for both established and emerging players alike.

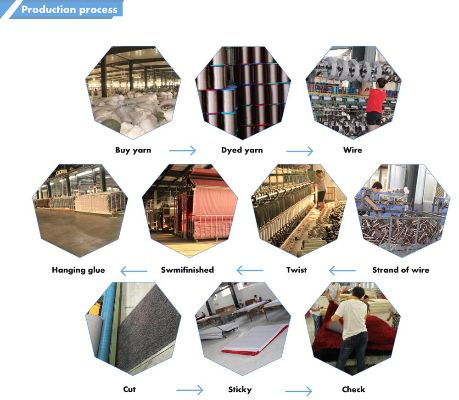

Introduction to Textile Mill Purchasing The textile industry is a crucial sector in the global economy, and its success often hinges on efficient purchasing processes. In this article, we will explore the various stages involved in the procurement process for textile mills, including market research, supplier selection, order processing, quality control, and logistics management. We will also provide an example of how these steps are applied in practice to demonstrate their importance in ensuring the success of textile mill operations.

Market Research Before any purchase decisions can be made, it is essential to conduct thorough market research to identify potential suppliers and evaluate their capabilities. This includes analyzing industry trends, competitor pricing strategies, and supplier performance metrics such as delivery times and quality standards. To facilitate this process, textile mills may use online databases, trade shows, and industry-specific networking events to gather information about potential suppliers.

Supplier Selection Once market research has been completed, textile mills must select the best suppliers based on factors such as price competitiveness, product quality, and delivery reliability. This involves evaluating supplier reputation through customer feedback and industry associations, and conducting on-site inspections to assess product quality and production capabilities. Some examples of supplier selection criteria might include minimum order quantity (MOQ) requirements, lead time commitments, and ability to meet tight delivery schedules.

Order Processing Once suppliers have been selected, textile mills proceed with order processing, which typically involves drafting purchase orders, negotiating prices, and confirming delivery details. It is important to ensure that all necessary documentation is provided and signed by both buyer and seller to establish legal ownership of the goods. Additionally, electronic payment systems should be used to streamline the payment process and reduce the risk of fraud.

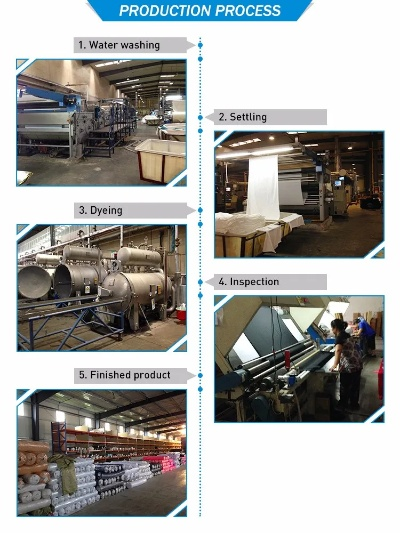

Quality Control Once the order is placed, textile mills must implement rigorous quality controls to ensure the products meet the required standards. This may involve receiving samples from suppliers, inspecting finished goods during production, or conducting third-party certification tests to verify compliance with safety and environmental regulations. Quality control procedures should be documented in a standardized manner to ensure consistency and transparency throughout the supply chain.

Logistics Management Finally, textile mills must manage the logistics of receiving and transporting the purchased goods to their final destination. This includes selecting appropriate shipping methods, calculating freight costs, and planning for customs clearance procedures. Proper inventory management software can assist with tracking shipment status, managing inventory levels, and identifying opportunities for cost savings through bulk purchasing or contractual discounts.

Case Study: Successful Textile Mill Purchase Process In the textile manufacturing industry, one company that has successfully implemented a comprehensive purchasing process is XYZ Textiles. XYZ Textiles began by conducting extensive market research to identify potential suppliers and evaluate their product quality and delivery capabilities. They then established clear supplier selection criteria, such as MOQ limits and lead time expectations, to ensure that only the best suppliers were selected for further evaluation.

Once a supplier was chosen, XYZ Textiles conducted detailed order processing, including drafting purchase orders and negotiation of prices. They also implemented a quality control system that included regular inspections and third-party certification tests to ensure product compliance with safety and environmental standards. Finally, XYZ Textiles managed the logistics of receiving and transporting the purchased goods using specialized inventory management software, which allowed them to monitor shipment status and optimize their logistics processes.

The result of this successful procurement process was increased efficiency and reduced costs. XYZ Textiles was able to quickly receive goods from reliable suppliers, avoid delays in production, and maintain high-quality products at competitive prices. This experience underscores the importance of implementing a well-planned purchasing process that considers all aspects of the supply chain, from market research to logistics management.

纺织厂采购流程概述

The Textile Mill Purchase Process

在纺织厂中,采购流程是一个重要的环节,它涉及到原材料的获取、供应商的选择、价格谈判以及后续的物流和交货等环节,下面我们将详细介绍纺织厂采购流程的主要步骤和要点。

采购流程的主要步骤

市场调研与需求分析

在采购开始之前,纺织厂需要进行市场调研和需求分析,了解行业趋势、市场需求以及竞争对手情况,这有助于确定采购的目标和范围。

供应商筛选与评估

根据市场调研和需求分析的结果,纺织厂需要筛选合适的供应商并进行评估,这包括对供应商的资质、产品质量、交货能力、价格等方面进行综合考虑。

询价与比价

在筛选出合适的供应商后,纺织厂需要向供应商发送询价单,了解产品的价格和质量等信息,还需要与其他供应商进行比较,选择性价比最高的供应商。

签订合同

经过比价和谈判后,纺织厂需要与确定的供应商签订采购合同,合同中应明确采购的产品、数量、交货时间、付款方式等条款。

采购流程中的案例说明

某纺织厂纺织品采购流程案例

某纺织厂在采购过程中,首先进行了市场调研和需求分析,明确了采购的目标是高质量的纺织品,该厂筛选了多家合格的供应商,进行了详细的供应商评估,在询价和比价过程中,该厂与多家供应商进行了多轮谈判,最终选择了性价比最高的供应商进行合作,该厂与该供应商签订了详细的采购合同,确保了采购的顺利进行。

采购流程表格补充说明(辅助文本)

纺织厂采购流程表格说明

| 步骤 | 描述 | 时间节点 | 关键点 |

|---|---|---|---|

| 市场调研与需求分析 | 了解行业趋势、市场需求及竞争对手情况 | 开始前 | 确定采购目标和范围 |

| 供应商筛选与评估 | 根据市场调研和需求分析结果筛选供应商并进行评估 | 开始后 | 综合考虑供应商资质、产品质量、交货能力等 |

| 询价与比价 | 向供应商发送询价单了解产品价格和质量等信息 | 进行中 | 进行多轮谈判选择性价比最高的供应商 |

| 签订合同 | 与确定的供应商签订采购合同明确采购的产品、数量、交货时间、付款方式等条款 | 结束前 | 确保合同条款的明确性和合法性 |

纺织厂采购流程是一个复杂而重要的过程,它涉及到多个环节和因素,在采购过程中,纺织厂需要做好市场调研和需求分析,筛选合适的供应商并进行评估,同时还需要进行询价和比价,最终选择性价比最高的供应商签订采购合同,通过规范的采购流程,可以确保采购的顺利进行和产品质量的有效控制。

Articles related to the knowledge points of this article:

Strategies for Effective Management in a Textile Factory

The Boss of Linhai Textile Factory

The Art of Textile Factory Plastic Belt Making

The Journey of Innovation at Jining JiaXiang Textile Factory