The Dynamics of the Hexing Textile Factory:A Case Study

This case study explores the complex dynamics of the Hexing Textile Factory, a prominent textile enterprise in China. The factory's success is attributed to its strategic positioning in the industry, its commitment to innovation and quality, as well as its ability to adapt to changing market demands. Through an analysis of the factory's operations, management strategies, and workforce development, this research aims to shed light on the factors that have contributed to its sustained growth and competitiveness in the global textile industry. The findings highlight the importance of effective leadership, a strong work culture, and a willingness to embrace change in order to succeed in today's dynamic business environment.

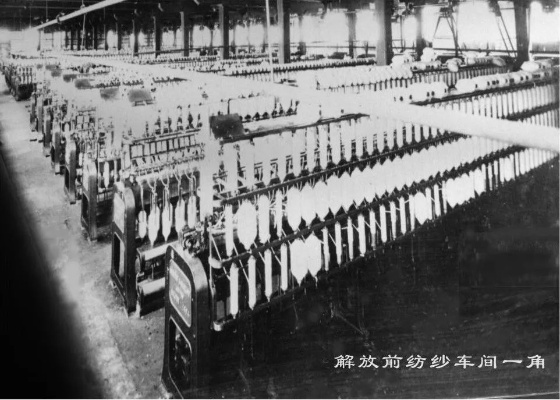

Introduction: The Hexing Textile Factory is a vibrant example of modern manufacturing in China. With over 100 years of history, this factory has undergone significant transformations to remain at the forefront of textile production. In this article, we will explore the key factors that have contributed to the success of Hexing Textile Factory and how they have evolved over time. We will also examine some of the challenges faced by the factory and how they were overcome through innovation and strategic planning.

History and Development: Hexing Textile Factory was founded in 1928 by Mr. He Xing, who saw the potential of textile manufacturing as a means of providing employment and economic growth in rural areas. Over the years, the factory expanded its production capacity and diversified its product range, eventually becoming one of the largest textile producers in China. Today, Hexing Textile Factory employs thousands of people and produces a wide range of fabrics, including cotton, polyester, and blended materials.

Key Factors:

-

Strong Supply Chain Management: Hexing Textile Factory has implemented advanced supply chain management systems that ensure timely delivery of raw materials and finished products to customers worldwide. This has helped the factory maintain a high level of customer satisfaction and competitiveness in the global market.

-

Innovation and Technology Adoption: The factory has invested heavily in research and development (R&D) to stay ahead of the competition. It has developed new technologies such as automated knitting machines and computer-controlled dyeing processes, which have significantly improved production efficiency and quality control.

-

Strategic Planning: Hexing Textile Factory has adopted a proactive approach to market trends and consumer preferences. The factory regularly analyzes market data and consumer behavior to develop new products and marketing strategies that meet the needs of its diverse customer base.

Challenges and Solutions:

-

Environmental Pressures: As the world becomes more aware of environmental issues, textile manufacturers face increased scrutiny on their sustainability practices. To address this, Hexing Textile Factory has implemented measures such as reducing water usage and using eco-friendly dyes in its production processes.

-

Global Trade Challenges: The global trade landscape has been challenging for Chinese manufacturers in recent years. To counteract these challenges, Hexing Textile Factory has strengthened its relationships with international partners and explored new markets outside China.

-

Labor Issues: The cost of labor has risen significantly in recent years, affecting the profitability of many factories. To mitigate this, Hexing Textile Factory has implemented measures such as offering better wages and benefits to attract and retain skilled workers.

Case Study: One notable case study is the development of sustainable materials for outdoor wear. In response to growing demand for eco-friendly clothing, Hexing Textile Factory launched a new line of outdoor apparel made from recycled polyester. This initiative not only addressed environmental concerns but also helped the factory differentiate itself from competitors in the market.

Conclusion: The success of Hexing Textile Factory is a testament to the power of innovation, strategic planning, and strong supply chain management. By staying ahead of industry trends and addressing challenges head-on, the factory has remained a vital player in the global textile industry. As the world continues to evolve, it will be interesting to see how Hexing Textile Factory adapts and grows to meet future demands.

和兴纺织厂

和兴纺织厂是一家历史悠久的纺织企业,以其精湛的工艺、优质的产品和良好的口碑在业界享有盛誉,该厂注重技术创新和绿色环保,致力于为客户提供高质量的纺织品。

和兴纺织厂的产品与服务

- 产品种类丰富:该厂生产各种类型的纺织品,包括棉布、丝绸、麻布等,满足不同客户的需求。

- 优质服务:和兴纺织厂注重客户体验,提供专业的纺织品咨询和售后服务,确保客户得到满意的产品和服务。

和兴纺织厂的运营模式

- 高效的生产流程:该厂采用先进的生产设备和技术,确保生产过程的效率和质量。

- 绿色环保理念:和兴纺织厂注重环保,采用环保材料和生产工艺,致力于实现绿色生产。

- 多元化经营模式:该厂通过多元化经营,拓展市场,提高竞争力。

案例分析——和兴纺织厂的成功经验

- 技术创新:和兴纺织厂注重技术创新,不断研发新产品和新工艺,提高产品质量和竞争力。

- 绿色环保:和兴纺织厂注重环保,采用环保材料和生产工艺,符合国家绿色发展政策。

- 客户体验:和兴纺织厂注重客户体验,提供专业的纺织品咨询和售后服务,赢得客户信任和支持。

表格补充说明:

表格1:和兴纺织厂的产品线展示

| 产品类型 | 主要产品 | 示例产品 |

|---|---|---|

| 棉布 | 纯棉面料 | 舒适透气、柔软舒适 |

| 丝绸 | 丝绸面料 | 华贵典雅、高贵气质 |

| 麻布 | 天然麻面料 | 健康环保、吸湿透气 |

案例说明:

客户满意度案例

某客户在和兴纺织厂购买了一批丝绸面料,经过一段时间的使用后,客户对其产品质量和舒适度表示非常满意,客户反馈说:“这款丝绸面料非常柔软舒适,穿着非常舒适。”该厂还提供了专业的纺织品咨询和售后服务,确保客户得到满意的产品和服务。

绿色环保实践案例

和兴纺织厂注重环保,采用环保材料和生产工艺,该厂在生产过程中严格控制废气、废水等污染物的排放,同时积极推广绿色生产理念,减少能源消耗和废弃物产生,该厂还积极参与环保公益活动,为社会做出贡献。

未来展望与建议

- 继续技术创新:和兴纺织厂将继续加强技术创新,提高产品质量和竞争力,该厂还将积极引进先进技术,提高生产效率和降低成本。

- 拓展市场:和兴纺织厂将继续拓展市场,提高品牌知名度和影响力,该厂还将加强与国内外其他企业的合作,共同开拓市场。

- 建议客户体验:和兴纺织厂建议客户在购买纺织品时,可以提供专业的纺织品咨询和售后服务,确保客户得到满意的产品和服务,该厂还将加强与客户的沟通和互动,提高客户满意度。

Articles related to the knowledge points of this article:

A Comprehensive Guide to Reaching the Zhengyang Textile Factory

The Hidden Traps of Textile Mills:An Unveiling of Pollution Emissions

A Night of Fire and Fury at the Shaoxing Textile Factory