The Fabrication Process of Textiles:A Journey Through the Stages

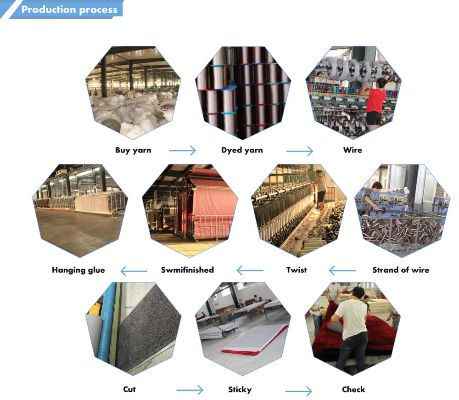

The process of fabricating textiles involves a series of stages that culminate in the creation of a finished product. The initial stage is the selection of raw materials, which are then processed into yarns or threads. These threads are then woven or knitted together to form the fabric. In the next step, the fabric undergoes further processing to enhance its quality and functionality. This may include treatments such as dyeing, printing, or laundering. Finally, the finished textile is packaged and shipped to its intended destination. The journey through these stages is a complex and meticulous process that ensures the end product meets the desired standards of quality, durability, and aesthetic appeal.

Introduction: Textiles, with their diverse range from everyday wear to high-end fashion, are an integral part of human life. From the raw materials to the final product, the fabrication process is a meticulous journey that involves multiple stages and technologies. In this talk, we will explore the various stages involved in the production of textiles, including yarn preparation, spinning, weaving, knitting, and finishing. We will also discuss some practical examples and case studies to illustrate how these processes work in real-world scenarios.

Yarn Preparation: Before any textile can be woven or knitted, it needs to be made into yarn. Yarn is a continuous thread composed of fibers that are twisted together. The first step in yarn preparation is the selection of raw materials such as cotton, wool, silk, polyester, etc. These materials are then processed into staple fibers, which are further converted into yarn by carding, twisting, and drawing.

Spinning: After preparing the yarn, it is spun into threads using a spinning machine. This process involves feeding the yarn through a spindle, which applies tension and rotation to the yarn. The result is a continuous thread called roving. Roving is then fed into a winder, where it is further processed into yarn.

Weaving: Once the yarn is ready, it is used to create fabric by weaving. Weaving involves interlacing two sets of threads, creating a pattern on the fabric. There are different types of weaving techniques, including plain weave, twill weave, satin weave, and others. Each technique has its own unique look and feel.

Knitting: Knitting is another popular method of producing textiles. It involves looping individual threads onto a needle and pulling them through to create a single row of stitches. Knitting produces a soft, warm fabric that is commonly used for sweaters, scarves, and other accessories.

Finishing: After weaving or knitting, the fabric may require additional finishing steps to enhance its appearance and durability. These include dyeing, printing, coating, and finishing such as sizing, blocking, and finishing with embellishments like buttons, sequins, and ribbons.

Case Study: One example of a successful textile production process is the production of luxury linen shirts by a well-known brand. The brand's production process starts with selecting high-quality linen yarn from sustainable sources. The yarn is then spun into thread and woven into shirts using a traditional weaving technique. The finished shirts undergo a thorough finishing process, including dyeing, printing, and finishing with embellishments like buttons and ribbons. The brand's commitment to sustainability and quality has made it one of the most sought-after brands in the industry.

Conclusion: The fabrication process of textiles is a complex and meticulous journey that involves multiple stages and technologies. From yarn preparation to finishing, each step plays an essential role in creating high-quality textiles that meet the needs and preferences of consumers worldwide. By understanding the process and learning from successful examples, we can continue to improve our textile production methods and contribute to the global textile industry's growth and sustainability.

大家好,今天我们将深入了解纺织品拉架的生产过程,在纺织行业中,拉架技术是一项关键环节,它涉及到原材料的选取、生产流程的规划以及质量控制等多个方面,下面我们将通过详细的图表和案例说明来详细介绍纺织品拉架的生产过程。

原材料准备

纤维选择

在拉架生产中,首先需要选择合适的纤维作为原材料,根据不同的需求和织物类型,纤维种类和性能各异,常见的纤维包括棉、涤纶、亚麻等。

纱线准备

纱线的质量直接影响到拉架产品的性能,在纱线准备阶段,需要确保纱线的质量稳定、均匀,满足生产需求。

生产流程

织布工序

织布工序是拉架生产的关键环节,将纤维按照一定的编织方式在织布机上织造出织物,这一过程需要严格控制织物的密度、厚度和纹理等参数。

拉力测试

在织布完成后,需要进行拉力测试,以确保产品的拉力性能符合要求,这一过程需要使用专业的设备和方法进行测试,确保产品的质量稳定可靠。

后续工序

在拉架生产过程中,还需要经过一系列后续工序,如涂层、染色、整理等,这些工序的顺利进行,才能最终完成纺织品拉架的生产。

案例说明

以某知名纺织品生产企业为例,其纺织品拉架生产过程如下:

-

原材料选择与准备:该企业选择优质棉纤维作为原材料,确保纤维的质量稳定,对纱线进行严格的筛选和测试,确保其质量符合生产要求。

-

生产流程规划:该企业制定了详细的生产流程,包括织布、拉力测试、后续工序等环节,在织布过程中,严格控制织物的密度、厚度和纹理等参数,确保产品的质量稳定可靠。

-

拉架产品特点:该企业生产的纺织品拉架具有优良的拉伸性能、耐磨性、耐洗性等特性,能够满足不同客户的需求,该企业注重产品质量控制,采用先进的生产工艺和设备,确保产品的质量稳定可靠。

图表补充说明

以下是纺织品拉架生产过程的图表补充说明:

(请在此处插入图表)

通过以上图表和案例说明,我们可以更好地了解纺织品拉架的生产过程,在实际生产中,还需要注意以下几点:

-

严格把控原材料的质量和性能,确保产品的质量稳定可靠。

-

制定合理的生产流程,确保生产过程的稳定性和可控性。

-

加强质量控制,采用先进的生产工艺和设备,提高生产效率和质量水平。

纺织品拉架的生产过程是一个复杂而精细的过程,需要严格控制各个环节的质量和性能,在实际生产中,还需要注重技术创新和工艺改进,不断提高生产效率和产品质量水平,还需要加强质量管理,确保产品的质量和安全性能符合要求。

Articles related to the knowledge points of this article:

The Story of Dongguan Xieyuan Textiles

The Dynamics and Innovation of Zunyi Textile Brand Womens Fashion

The Impact of Textile Import Tariffs on Global Trade and the Fashion Industry