The Fabric of Future:Exploring the World of Textile Manufacturing

"The Fabric of Future: Exploring the World of Textile Manufacturing",This article explores the future of textile manufacturing, focusing on its potential impact on the industry. The author argues that with advancements in technology and increased demand for sustainable and eco-friendly materials, the future of textile manufacturing will be shaped by innovation and sustainability.,One major trend in the future of textile manufacturing is the use of digital technologies such as artificial intelligence and machine learning to improve efficiency and reduce waste. This will enable manufacturers to produce more products quickly and efficiently while also reducing their environmental impact.,Another important aspect of the future of textile manufacturing is the focus on sustainability. As consumers become more aware of the environmental impact of their consumption, manufacturers must prioritize using sustainable materials and practices to meet their demands. This includes using renewable energy sources, reducing water usage, and minimizing waste production.,Overall, the future of textile manufacturing looks promising, with new technologies and sustainable practices driving innovation and growth. As the industry continues to evolve, it is important for manufacturers to stay ahead of the curve and embrace change to meet the needs of a rapidly changing consumer market.

In today's world, textile manufacturing is not just a mere process of creating fabrics; it's a multifaceted industry that plays a crucial role in shaping our daily lives. From the softness of a cozy sweater to the durability of a tough work shirt, textiles have become an integral part of human existence. In this article, we will delve into the fascinating world of textile manufacturing, exploring its diverse processes, innovative technologies, and the impact it has on global economies.

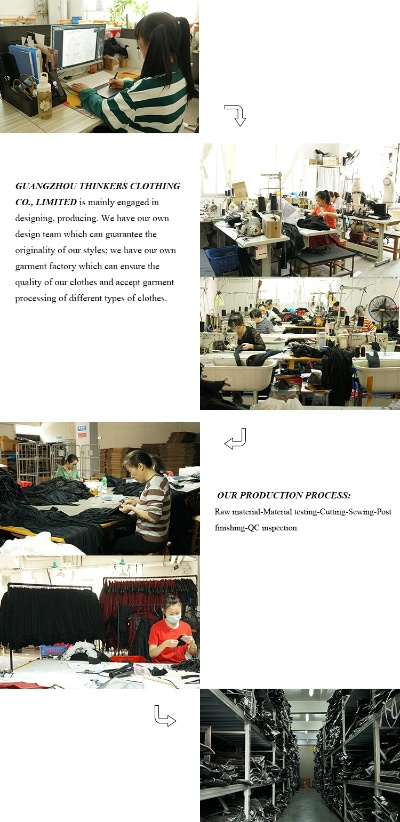

Textile manufacturing encompasses a wide range of activities, from the raw materials used in the production to the final products sold in stores. Let's start by taking a closer look at the different stages involved in the textile production process.

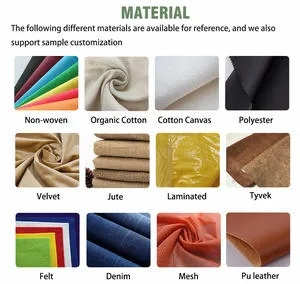

Raw Materials

The foundation of any textile manufacturing process starts with the selection of high-quality raw materials. These include cotton, polyester, wool, silk, and other natural fibers as well as synthetic materials like nylon and spandex. These raw materials are sourced from various parts of the world, depending on their availability and cost efficiency. For instance, cotton is grown in tropical regions, while polyester is produced in chemical factories across the globe.

Weaving and Knitting

Once the raw materials are gathered, they undergo various processes before becoming finished textiles. Weaving involves interlacing threads to create a fabric, while knitting involves looping threads together to form a closed structure. Both techniques are essential for producing woven and knitted fabrics. For example, a simple t-shirt can be made using a variety of weaves such as plain weave, satin weave, and even jersey weave. Similarly, a pair of jeans could be knitted using different stitch patterns.

Dyes and Printing

Colorful textiles are created through dyeing and printing processes. Dyes are applied to the fabric to change its color, while printing involves applying designs directly onto the fabric using screens or other printing techniques. This allows manufacturers to create unique patterns and designs that reflect the latest fashion trends. For example, a company might use digital printing technology to produce high-quality T-shirts with intricate designs that are both eco-friendly and visually appealing.

Finishing

After the dyeing and printing process, the textiles undergo finishing treatments to enhance their appearance and durability. This includes treatments such as steaming, scouring, and finishing with waxes or oils. These treatments help protect the fabric against wear and tear, making it more resistant to fading and stains. For instance, a company might use a finish called "silk" to give their linen sheets a smooth, lustrous finish that makes them feel luxurious and comfortable.

Packaging and Shipping

Once the textiles are finished and ready for sale, they need to be packaged and shipped to retailers or consumers. This stage involves careful consideration of how the textiles will be transported and stored during transit. It's important to ensure that the packaging is sturdy enough to prevent damage during shipping and that the textiles are protected from dust, moisture, and other environmental factors. For example, a company might use biodegradable packaging materials to reduce their environmental impact while still ensuring that the textiles arrive safely at their destination.

Innovations in Textile Manufacturing

As technology continues to advance, so too does textile manufacturing. New innovations in machinery, materials, and processes are transforming the industry. For example, automated machines are being developed to increase production efficiency while reducing labor costs. Additionally, new materials like recycled plastics and bio-based fibers are being introduced to reduce waste and promote sustainability.

One such innovative textile manufacturing case study is the development of sustainable textiles. Many companies are now focusing on using organic and recycled materials to produce clothing and accessories that are both stylish and environmentally friendly. For example, a company might use bamboo fibers to make their linen sheets, which are naturally resistant to mold and bacteria. Another example is the use of recycled water bottles to create eco-friendly fabrics for outdoor gear.

Conclusion

Textile manufacturing is a complex and dynamic industry that plays a vital role in shaping our world. From the selection of raw materials to the final product, every step of the process is carefully crafted to meet the needs of consumers and the environment. As technology continues to advance, we can expect even more innovative solutions to emerge in this field, further enhancing our ability to create textiles that meet our ever-evolving needs.

In conclusion, textile manufacturing is not just about creating clothing or household items; it's about crafting a beautiful and functional world for us all. By understanding the various stages involved in the production process and exploring innovative technologies, we can continue to push the boundaries of what's possible in this exciting industry.

纺织品制造概述

随着全球经济的快速发展,纺织品制造业已成为一个重要的产业,纺织品不仅在日常生活中扮演着关键角色,而且在服装、家居装饰、户外用品等领域都有着广泛的应用,本文将围绕纺织品制造的主题,从原料选择、生产工艺、质量控制等方面进行深入探讨。

原料选择

- 天然纤维:天然纤维是纺织品制造的基础,棉花、蚕丝、麻等都是常见的天然纤维原料,这些纤维具有环保、可持续、天然等优点,符合现代人们对绿色生活的追求。

- 合成纤维:随着科技的发展,合成纤维已经成为纺织品制造的重要原料之一,常见的合成纤维包括涤纶、尼龙等,这些纤维具有优良的耐久性、强度和弹性,能够满足不同领域的需求。

生产工艺

- 纺织设备:纺织设备是纺织品制造的关键设备,从梭织机、针织机到印花机、染整设备等,每一种设备都有其特定的用途和功能。

- 染色技术:染色是纺织品制造中的重要环节,不同的染料和染色工艺可以产生不同的颜色和纹理,现代染色技术已经非常成熟,能够满足不同客户的需求。

- 质量控制:在纺织品制造过程中,质量控制是非常重要的环节,从原材料的检验到生产过程的监控,再到成品的质量检测,每一个环节都需要严格控制。

案例分析

以某知名纺织品制造企业为例,该企业采用先进的纺织设备和染色技术,专注于生产高品质的纺织品,该企业的原料选择非常广泛,包括各种天然纤维和合成纤维,在生产工艺方面,该企业注重细节,从纺织设备的选择到染色工艺的调整,都经过了严格的测试和优化,在质量控制方面,该企业非常重视每一个环节的质量检测,确保每一件产品都符合高标准的质量要求。

随着科技的不断发展,纺织品制造行业将会迎来更多的机遇和挑战,纺织品制造行业将会更加注重环保、可持续性、个性化等方向的发展,随着消费者对纺织品品质和环保性的要求不断提高,纺织品制造企业需要不断创新和改进生产工艺和质量控制体系,以满足消费者的需求。

纺织品制造是一个涉及多个方面的产业,包括原料选择、生产工艺、质量控制等方面,在纺织品制造过程中,企业需要注重环保、可持续性、个性化等方向的发展,同时还需要不断创新和改进生产工艺和质量控制体系,以满足消费者的需求,通过不断的技术创新和改进,纺织品制造行业将会迎来更加美好的未来。

Articles related to the knowledge points of this article:

Transformative Journey:A Case Study of Nanjing Textiles Co.Ltd.

The Journey of Golden Beads:The Story of 金豆豆纺织品