Navigating the World of Textile Inventory Management

Textile inventory management is a crucial aspect of any textile business, as it ensures that the right amount of fabric is available for production and sales. This process involves tracking the movement of textiles from their source to the end consumer, including monitoring their quality and condition. To effectively manage this inventory, businesses must implement robust systems that can accurately track the stock levels, identify trends, and make informed decisions about purchasing and selling strategies. Additionally, these systems should be integrated with advanced technologies such as artificial intelligence and machine learning, which can help predict demand and optimize supply chains. By doing so, textile companies can streamline their operations, reduce waste, and increase profitability while maintaining a competitive edge in the market.

Introduction: In today's competitive global marketplace, textile companies are constantly faced with the challenge of managing their inventory effectively. Properly managing inventory not only helps to ensure a steady supply of products but also minimizes waste and maximizes profitability. This talk will explore the intricacies of textile inventory management, highlighting strategies for efficient inventory tracking, forecasting, and replenishment. We will also delve into practical examples that illustrate how these principles can be applied in real-world scenarios.

Textile Inventory Management Basics:

Table 1: Key Points in Textile Inventory Management | Key Point | Description | |------------|-------------| | Inventory Level | The quantity of stock currently held by the company. | | Replenishment Frequency | How often items are restocked based on demand or sales volume. | | Demand Forecasting | A method used to predict future sales volume based on historical data and market trends. | | Supply Chain Integration | The ability to integrate supply chain processes to improve inventory accuracy and efficiency. |

Table 2: Example of Textile Inventory Management Strategies | Inventory Management Strategies | Description | |------------------------|------------| | Just-in-Time (JIT) | A philosophy where goods are produced as needed rather than being held in inventory. | | Economic Order Quantity (EOQ) Model | A mathematical model used to determine the optimal number of units to order at any given time. | | Kanban System | A visual management system that uses cards to control flow of materials through an assembly line. | | ERP Systems | Enterprise resource planning systems that automate many aspects of inventory management. |

Case Study: Successful Textile Inventory Management

Company A is a leading supplier of high-quality textiles to various retail and industrial clients. To manage its inventory effectively, Company A implemented a comprehensive inventory management system that included JIT practices, EOQ calculations, Kanban cards, and ERP integration.

The company's inventory management strategy was centered around reducing lead times and minimizing overstocking. By implementing JIT, Company A was able to produce just enough textiles to meet customer demand, thus eliminating the need for excess inventory. Additionally, the company used EOQ calculations to determine the optimal order quantities for each product based on sales forecasts and market trends.

The Kanban system helped streamline the production process, ensuring that materials were always available when they were needed. Finally, integrating the ERP system allowed Company A to track inventory levels, monitor sales, and make accurate forecasts, all while improving overall efficiency and reducing costs.

Over the course of several years, Company A's inventory management strategy proved to be highly effective. It enabled the company to maintain a low level of inventory, reduce waste, and increase profitability. As a result, the company has grown steadily in both its domestic and international markets, thanks in large part to its sophisticated inventory management system.

Conclusion:

In conclusion, textile inventory management is a critical aspect of running a successful business. By understanding the basics of inventory management, implementing effective strategies such as JIT, EOQ, Kanban, and ERP integration, and applying them in real-world scenarios, businesses can optimize their inventory levels, minimize waste, and maximize profitability. As demonstrated by Company A, a well-implemented inventory management system can transform a company's operations, enabling it to thrive in a rapidly changing global marketplace.

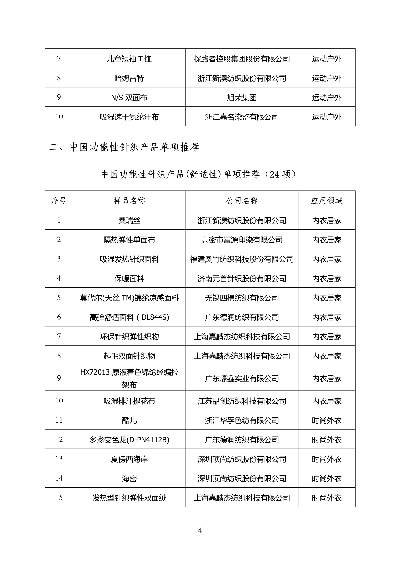

纺织品收库存背景介绍

在纺织品行业,随着市场竞争加剧和消费者需求多样化,库存管理变得越来越重要,特别是在纺织品收库存阶段,企业需要精细化管理库存,确保供应链顺畅,提高运营效率,本文将围绕纺织品收库存的主题,探讨相关问题及解决方案。

纺织品收库存现状分析

- 库存积压情况:当前,许多纺织品企业面临着库存积压的问题,由于市场需求波动、产品更新换代等原因,部分产品未能及时销售出去,导致库存积压。

- 库存管理问题:企业在库存管理方面存在诸多问题,如采购与生产计划不匹配、库存信息不透明、缺乏有效的库存预警机制等。

案例分析

以某纺织品企业为例,该企业在纺织品收库存阶段采用了以下措施:

- 精细化管理:企业通过建立完善的采购与生产计划体系,确保采购与生产之间的匹配度,采用先进的库存管理系统,实时监控库存情况,及时发现并处理积压库存。

- 优化供应链:企业加强与供应商的沟通与合作,确保原材料供应稳定,积极拓展销售渠道,提高产品销售量。

解决方案与措施

针对上述案例中的问题及现状,提出以下解决方案与措施:

- 采购与生产计划优化:企业应加强与供应商的沟通与合作,根据市场需求变化及时调整采购和生产计划,建立完善的预警机制,提前预测市场需求变化,避免库存积压。

- 引入先进技术手段:企业可以引入先进的库存管理系统和数据分析工具,提高库存管理效率,使用物联网技术实现库存实时监控和预警,提高库存管理水平。

- 加强员工培训:企业应加强员工培训,提高员工对库存管理的认识和技能水平,建立完善的考核机制,确保员工能够熟练掌握库存管理技能。

具体实施步骤

- 制定详细的管理计划:企业应制定详细的收库存管理计划,明确收货、存储、销售等各个环节的管理要求。

- 采购与生产协调:企业应与供应商和制造商协调好采购和生产计划,确保供应链顺畅,加强与销售渠道的沟通与合作,提高产品销售量。

- 引入先进技术手段:企业可以与相关技术公司合作,引入先进的库存管理系统和数据分析工具,使用物联网技术实现实时监控和预警功能。

- 实施监控与调整:企业应实时监控库存情况,及时发现并处理积压库存,根据市场需求变化和销售情况及时调整管理策略。

- 总结经验教训:在收库存阶段结束后,企业应对本次活动进行总结经验教训,为今后的收库存管理提供参考。

纺织品收库存是企业供应链管理中的重要环节,对于确保供应链顺畅、提高运营效率具有重要意义,通过精细化管理、优化供应链、引入先进技术手段等措施,可以有效解决纺织品收库存中的问题,企业应加强员工培训和管理,提高员工对库存管理的认识和技能水平,在实施过程中,企业应制定详细的管理计划、协调好采购与生产计划、引入先进技术手段并实施监控与调整等步骤,通过以上措施的实施,可以有效解决纺织品收库存中的问题,提高企业的运营效率和管理水平。

Articles related to the knowledge points of this article:

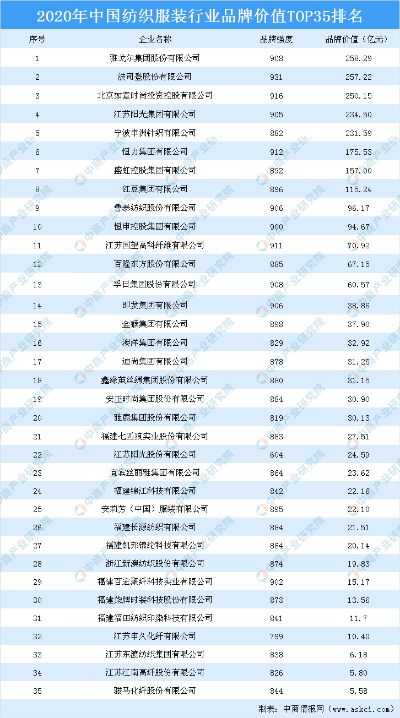

Top Ten Textile Brands in the rankings of textile brands

The Global Fabric of Anglo-American Trade:An Analysis of Anglophile Textiles