The Multifaceted Journey of Textile Production:An Overview

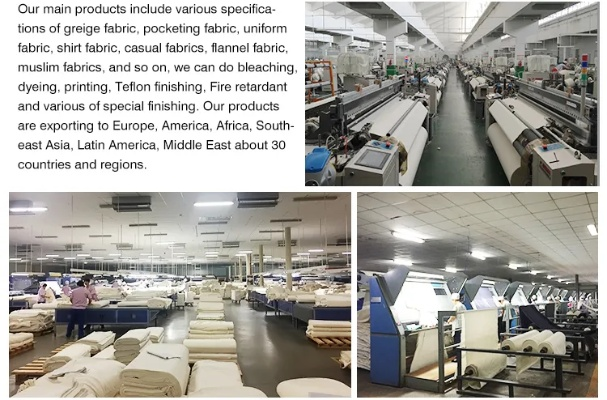

The textile industry, a multifaceted journey that spans across various stages of production, from raw materials to finished products, is an intricate tapestry of human endeavor. The process involves the cultivation of fibers, their processing into yarns and fabrics, and finally, the transformation of these raw materials into garments, furnishings, and other textile goods. This comprehensive overview delves into the intricacies of this complex journey, highlighting the interconnectedness of each stage and the critical role each plays in shaping the final product. From the initial extraction of natural resources to the final assembly of consumer goods, every step of this journey is vital in ensuring the sustainability and quality of the textile industry. As we move forward, it is essential to continue optimizing these processes, promoting innovation, and ensuring that the future of textile production remains vibrant and thriving.

Introduction: Textile production is a complex process that involves multiple stages and techniques, from raw material procurement to finished product assembly. In this article, we will delve into the various stages of textile manufacturing, including cutting, weaving, knitting, and finishing, and explore how they work together to create high-quality fabrics. We will also examine some successful case studies to illustrate the impact of these processes on both industry and consumer goods.

Cutting: The cutting process is the first step in textile production, where raw materials are transformed into smaller pieces called threads. This stage is crucial as it determines the final texture and pattern of the fabric. The cutting process can be manual or automated, depending on the size and complexity of the project. Here's an example of a simple table showing the different types of cutting machines used in textile production:

| Cutting Machine | Type | Application |

|---|---|---|

| Rotary Cutter | Manual | Useful for small quantities or intricate designs |

| Sheet Cutter | Automated | Suitable for large-scale production |

| Slitting Machine | Manual | Preferred for delicate fabrics |

| Patterning Machine | Automated | Essential for creating intricate patterns |

Weaving: After cutting, the next step is weaving, which involves interlacing the threads to form a three-dimensional structure. There are several types of weaving methods, including warp weaving, satin weaving, and jacquard weaving, each with its unique characteristics. Let's take a look at a table that outlines the different types of weaving:

| Weaving Method | Description |

|---|---|

| Warp Weaving | In this method, threads are laid out in a grid pattern and then pulled tight to create a strong foundation for the fabric. |

| Satin Weaving | In this technique, the threads are woven in a diagonal pattern, resulting in a smooth, shiny surface. |

| Jacquard Weaving | This method allows for intricate patterns to be created by using movable needles that correspond to specific colors or designs. |

Knitting: Knitting is a similar process to weaving but uses loops instead of threads. Knitting creates a softer, more flexible fabric that is often used for sweaters, hats, and other accessories. Here's an example of a table that compares the two methods:

| Weaving Method | Knitting Method | Description |

|---|---|---|

| Warp Weaving | Knitting | Creates a strong foundation for the fabric by pulling tight threads through a circular pattern |

| Satin Weaving | Knitting | Results in a smooth, shiny surface due to the diagonal pattern of the loops |

| Jacquard Weaving | Knitting | Allows for intricate patterns to be created using movable needles that correspond to specific colors or designs |

Finishing: Finally, the final step in textile production is finishing, which involves enhancing the fabric's appearance and durability. Finishing techniques include dyeing, printing, embroidery, and coating. Let's take a look at a table that shows some common finishing methods:

| Finishing Method | Description |

|---|---|

| Dyeing | Applying color directly to the fabric using chemicals or heat |

| Printing | Using ink or other substances to create patterns on the fabric |

| Embroidery | Stitching small details onto the fabric using thread or beads |

| Coating | Applying a layer of protective material such as wax or oil to the fabric |

Case Study: One example of a successful textile company is Pima Mills, based in Arizona. Founded in 1908, Pima Mills specializes in producing high-quality cotton and linen fabrics for the home furnishings industry. The company's success can be attributed to several factors, including its focus on sustainable practices, innovative design, and customer service. For example, Pima Mills has implemented a system of rotational weaving machines to minimize waste and improve efficiency. Additionally, the company has partnered with local artisans to produce hand-woven rugs and tapestries, showcasing their commitment to preserving traditional craftsmanship.

Conclusion: Textile production is a multifaceted journey that involves cutting, weaving, knitting, and finishing. Each stage plays a crucial role in creating high-quality fabrics that meet the needs of consumers around the world. By examining successful case studies like Pima Mills, we can gain insights into how these processes can lead to innovation, sustainability, and customer satisfaction. As we continue to advance in technology and demand ever-increasing levels of quality, it's clear that the textile industry will continue to evolve and shape the future of fashion and design.

纺织厂几种工序概述

纺织厂是制造纺织品的重要场所,其工序繁多,涵盖了从原材料准备到成品出产的整个生产流程,以下简要介绍纺织厂中的几种主要工序及其特点。

原料准备工序

原料准备工序是纺织厂的起始环节,主要涉及纤维的挑选、混合和预处理等,在这个阶段,工作人员根据不同的纤维类型和织物需求,选择合适的原料,确保后续工序顺利进行。

原料准备工序的表格说明:

原料种类 | 描述 ---|---|--- 天然纤维 | 如棉、麻、丝等 合成纤维 | 如涤纶、尼龙等 预处理方法 | 清洗、梳理、混合等

织造工序

织造工序是纺织厂的核心环节,涉及将纤维通过编织工艺制成织物,常见的织造方法包括平纹织造、斜纹织造、提花织造等,在这个工序中,工作人员根据设计图纸或客户要求,使用各种织布机器和设备,将纤维按照特定的图案和结构编织成织物。

织造工序的案例说明:

某纺织厂采用先进的数码印花技术进行织造,该厂根据客户需求,使用数码印花机将图案印在纱线上,然后通过一系列的编织工艺,最终生产出具有独特纹理和图案的纺织品。

后处理工序

后处理工序是纺织厂中的一道重要工序,主要涉及染料染色、整理和烘干等,工作人员根据不同的织物类型和颜色要求,选择合适的染料和整理剂,对织物进行染色和整理,使其达到特定的颜色、质地和外观要求。

后处理工序的表格说明:

工序名称 | 后处理步骤 ---|---|--- 染料染色 | 选择染料、染色工艺等 整理剂使用 | 如防皱处理、柔软剂添加等 烘干设备 | 确保织物干燥、定型

纺织厂工序案例分析

以某纺织厂为例,详细分析其几种主要工序及其案例。

原料准备工序案例分析

该纺织厂在原料准备阶段采用了先进的纤维挑选和混合技术,确保了原材料的质量和稳定性,该厂还采用了环保型的清洗和整理设备,减少了环境污染,在未来的发展中,该厂将继续优化原料准备流程,提高生产效率和产品质量。

织造工序案例分析

该纺织厂采用先进的数码印花技术进行织造,该技术可以根据客户需求快速生成图案和纹理,提高了生产效率,该厂还采用了环保型的染料和整理剂,确保了织物的质量和环保性,在未来的发展中,该厂将继续探索新的织造技术,提高生产效率和产品质量。

结论与展望

纺织厂是制造纺织品的重要场所,其工序繁多,涵盖了从原材料准备到成品出产的整个生产流程,在未来的发展中,纺织厂需要不断优化生产工艺和技术,提高生产效率和产品质量,纺织厂还需要注重环境保护和可持续发展,采取有效的措施减少环境污染和资源浪费。

Articles related to the knowledge points of this article:

The Story of Lanyixu Fuchang Textile Factory