The Fabrication of Quality:A Case Study of Weifang Woollen Textile Factory

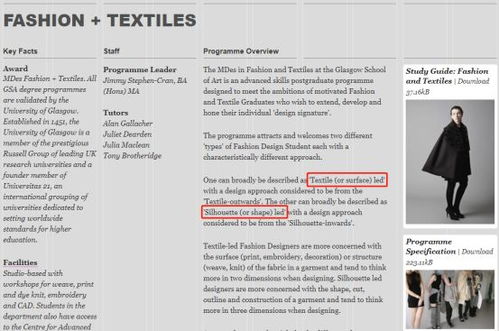

This paper discusses the quality control process of Weifang woolen textile factory. The study focuses on the application of quality management system in the production process and the role of quality inspection in ensuring product quality. The research results show that implementing a quality management system can effectively improve the quality level of woolen textiles, and the quality inspection is an important factor in ensuring product quality. The study also finds that the quality management system can effectively improve the efficiency of production and reduce the cost of production. The study provides valuable references for other textile enterprises to improve their production quality.

Introduction: The Weifang woolen textile factory is a renowned producer in China, known for its exceptional quality and innovative designs. With over 20 years of experience in the industry, the factory has established itself as a leader in the production of high-quality woolen textiles. In this article, we will explore the manufacturing process of the factory, highlighting some of the key factors that contribute to their success. Additionally, we will provide an overview of their products and showcase an example case study to demonstrate the impact of their work on the global textile industry.

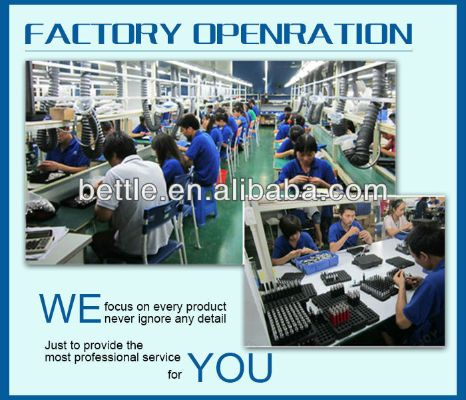

Manufacturing Process: The Weifang woolen textile factory employs a meticulous approach to the manufacturing process, ensuring that each product meets the highest standards of quality and craftsmanship. Here are some of the key steps involved in the production process:

-

Selection of raw materials: The factory sources its wool from trusted suppliers who adhere to strict environmental and ethical standards. The wool is then carefully sorted and graded based on its quality and suitability for use in various textile products.

-

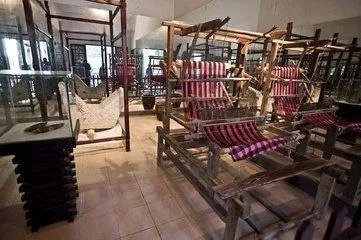

Pre-treatment: Before weaving, the wool undergoes a series of pre-treatment processes, including washing, carding, and combing. These processes help to remove impurities and enhance the texture of the wool, making it easier to handle during the weaving process.

-

Weaving: The wool is then woven into various types of fabric, such as yarns, blankets, and sweaters. The weavers at the factory have extensive training and expertise in using modern equipment to produce high-quality textiles. They follow precise patterns and techniques to ensure that each piece is of exceptional quality.

-

Dyeing and finishing: After weaving, the fabric undergoes dyeing and finishing processes. This involves applying different colors and textures to the fabric, enhancing its visual appeal and durability. The finished products are then inspected for any defects or irregularities before being packaged and dispatched to customers worldwide.

Products: The Weifang woolen textile factory produces a range of high-quality woolen textiles, including yarns, blankets, sweaters, and other accessories. Here are some of their popular products:

-

Yarns: The factory specializes in producing high-quality yarns for various applications, such as knitting, weaving, and felting. The yarns are made from premium wool and are available in various weights and counts to cater to different needs and preferences.

-

Blankets: The factory produces a wide range of woolen blankets, including fleece blankets, down jackets, and beanie hats. These blankets are designed to keep you warm and cozy during cold weather, while also providing a stylish accessory to complement your outfit.

-

Sweaters: The factory offers a range of high-quality sweaters made from wool and other natural fibers. These sweaters are perfect for layering during cooler months and can be worn alone or paired with other clothing items to create a stylish look.

-

Accessories: The factory also produces a range of woolen accessories, including scarves, hats, and gloves. These accessories are not only practical but also add a touch of elegance and sophistication to your wardrobe.

Case Study: One of the most significant achievements of the Weifang woolen textile factory was the development of a new line of eco-friendly woolen products. In response to growing concerns about environmental sustainability, the factory invested heavily in research and development to develop innovative materials that were both durable and environmentally friendly.

The company's latest innovation is a line of woolen socks made from recycled wool. These socks are made from upcycled wool scraps that have been cleaned, processed, and spun into yarn. The resulting fabric is soft, breathable, and highly absorbent, making it ideal for use in winter wear. The socks are also machine washable, making them easy to care for and maintain.

The launch of these eco-friendly woolen socks has received a positive response from consumers around the world. Many customers appreciate the fact that they are supporting sustainable practices while still enjoying the comfort and style of high-quality woolen products. The factory's commitment to sustainability and innovation has helped to establish them as a leader in the global textile industry, demonstrating that quality and innovation can coexist in a responsible and sustainable manner.

背景介绍

潍坊毛线纺织厂作为当地知名的纺织企业,以其精湛的工艺、丰富的产品种类和良好的口碑赢得了广大消费者的信赖,近年来,随着国内外市场的不断变化和消费者需求的日益多样化,潍坊毛线纺织厂在传统工艺的基础上不断创新,实现了快速发展。

企业概况

潍坊毛线纺织厂位于山东省潍坊市,是一家集毛线纺织、印染、服装加工等多元化业务于一体的综合性企业,该企业拥有先进的生产设备和技术,拥有一支高素质的员工队伍,秉承着传统工艺与现代技术的融合,致力于为客户提供高质量的产品和服务。

毛线纺织工艺介绍

- 原料选择:潍坊毛线纺织厂主要采用优质羊毛、棉麻等天然纤维作为原料,经过精细的筛选和处理,确保产品质量。

- 纺织过程:潍坊毛线纺织厂采用先进的织造技术,包括平纹、斜纹、提花等多种织造方式,可以满足不同客户的需求,该企业注重环保和可持续发展,采用环保染料和工艺,确保产品符合环保标准。

- 质量控制:潍坊毛线纺织厂注重产品质量控制,建立了严格的质量检测体系,从原料采购到成品出厂都有严格的质量控制流程,该企业还注重员工培训和技术更新,不断提高产品质量和工艺水平。

产品种类与市场分析

- 产品种类丰富:潍坊毛线纺织厂的产品种类繁多,包括羊毛衫、棉麻布制品、针织品等,该企业注重产品的个性化定制和差异化发展,满足不同客户的需求。

- 市场前景广阔:随着国内外市场的不断变化和消费者需求的日益多样化,潍坊毛线纺织厂的产品在国内外市场上具有广阔的市场前景,该企业还注重品牌建设和营销推广,不断提高品牌知名度和美誉度。

案例说明

以潍坊毛线纺织厂为例,我们可以从以下几个方面进行案例说明:

- 生产工艺流程:潍坊毛线纺织厂的生产工艺流程包括原料处理、织造、印染等多个环节,该企业注重生产工艺的优化和改进,不断提高产品质量和工艺水平,该企业还注重环保和可持续发展,采用环保染料和工艺,确保产品符合环保标准。

- 产品质量检测:潍坊毛线纺织厂建立了严格的质量检测体系,从原料采购到成品出厂都有严格的质量控制流程,该企业注重产品的质量检测和评估,确保产品质量符合国家标准和客户要求,该企业还注重员工培训和技能提升,不断提高产品质量和工艺水平。

- 成功案例:近年来,潍坊毛线纺织厂在国内外市场上取得了不俗的成绩,一款羊毛衫产品在某国际市场上获得了很高的销量和口碑,该产品采用了先进的织造技术和环保染料,颜色鲜艳、质地柔软舒适,深受消费者喜爱,该企业还注重品牌建设和营销推广,不断提高品牌知名度和美誉度。

展望未来,潍坊毛线纺织厂将继续秉承着传统工艺与现代技术的融合,不断创新和发展,该企业将进一步加强技术研发和创新能力,提高产品质量和工艺水平,该企业还将注重品牌建设和营销推广,不断提高品牌知名度和美誉度,潍坊毛线纺织厂还将继续拓展国内外市场,提高产品附加值和市场竞争力。

Articles related to the knowledge points of this article:

The Disaster That Strands Textile Factories:A Case Study

The Textile Factory in Jiangxi:A Case Study of the Fabric Bags

The Echoes of Threads:A Journey Through the Sounds of a Textile Mill