The Innovative Approach to Textile Factory Design:A Comprehensive Guide

"The Innovative Approach to Textile Factory Design: A Comprehensive Guide" is a comprehensive guide that provides a detailed and innovative approach to the design of textile factories. The guide covers various aspects of textile factory design, including layout planning, equipment selection, and operational management. It emphasizes the importance of considering factors such as production efficiency, quality control, and safety in the design process. Additionally, the guide includes case studies and examples of successful textile factory designs, which can provide valuable insights for other textile factories. Overall, this comprehensive guide provides a valuable resource for those who are involved in the design and operation of textile factories.

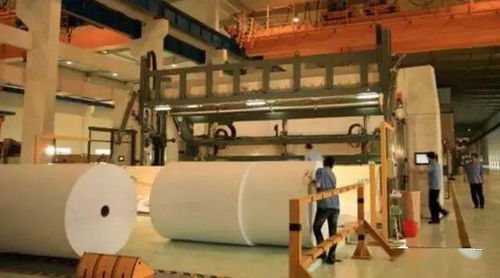

Introduction: Textile factories are the backbone of the global textile industry, producing a wide range of fabrics and garments for both domestic and international markets. With the increasing demand for sustainable and eco-friendly materials, the design of these factories has become more critical than ever before. In this guide, we will explore the key aspects of designing a modern textile factory, including layout planning, energy efficiency, waste management, and safety measures. By understanding these principles, you can create a textile factory that not only meets current standards but also sets new benchmarks in sustainability and efficiency.

Layout Planning: The layout of a textile factory is crucial in determining its efficiency and productivity. Here are some key considerations:

-

Workshop Areas: Each workshop should be designed to optimize workflow and minimize wasted space. For example, if your factory produces knitwear, separate knitting and dyeing areas would be necessary to maintain high quality control.

-

Warehouse Areas: These should be strategically placed to facilitate easy access to finished goods and raw materials. Consider using modular warehouse designs that can be easily modified or expanded as needed.

-

Storage Areas: Proper storage solutions are essential for maintaining inventory accuracy and reducing waste. For instance, using pallets instead of bulky cardboard boxes can help reduce clutter and increase storage capacity.

-

Maintenance Areas: These should be located away from the main production areas to minimize disruptions during downtime.

-

Utility Rooms: These rooms should be equipped with efficient lighting, heating, and ventilation systems to ensure optimal working conditions.

-

Safety Areas: Ensure that emergency exits, fire extinguishers, and other safety equipment are clearly marked and easily accessible.

Energy Efficiency: Incorporating energy-efficient technologies into your textile factory design can significantly reduce operating costs and improve environmental performance. Here are some tips:

-

Solar Power: Install solar panels on the roof of your factory to generate renewable energy. This can significantly reduce your electricity bills and lower your carbon footprint.

-

Energy-Saving Lighting: Use LED lights where possible to replace traditional incandescent bulbs. LEDs consume less energy and last longer, reducing maintenance costs over time.

-

Heat Recovery Systems: Use heat recovery systems to recover waste heat generated by machinery and use it to heat water or steam for industrial processes.

-

Water Conservation: Install water-efficient fixtures and appliances in your factory, such as low-flow showerheads and faucets. This can save significant amounts of water and reduce your water bills.

Waste Management: Waste management is an essential aspect of any textile factory design. Here are some strategies to consider:

-

Recycling: Encourage customers to recycle textile scraps by offering recycling programs and incentives. This not only reduces waste but also generates revenue through recycled materials.

-

Composting: If your factory produces organic textiles, consider implementing a composting system to turn waste into nutrient-rich soil. This can be especially beneficial for farms that grow crops using organic inputs.

-

Energy Recovery: Use waste heat from industrial processes to generate electricity or heat water for other purposes. This can significantly reduce your energy consumption and greenhouse gas emissions.

Safety Measures: Safety is paramount in any textile factory design. Here are some important considerations to ensure a safe work environment:

-

Hazardous Materials: Ensure all hazardous chemicals and materials are stored and handled properly according to regulations. This includes ensuring proper labeling, secure storage, and regular training for employees.

-

Fall Protection: Install fall protection systems in high-risk areas, such as scaffolding or ladders, to prevent accidents caused by falls.

-

First Aid Kits: Provide first aid kits for all employees, including those who may be exposed to harmful chemicals or physical hazards.

-

Training Programs: Regularly train employees on safety procedures and emergency response plans. This can help minimize workplace accidents and injuries.

Case Study: One innovative textile factory design that stands out is the "Green Textile Factory" in San Francisco, California. The factory uses a combination of advanced technology and sustainable practices to produce high-quality, eco-friendly textiles. Here are some key features of the factory's design:

-

Solar-Powered Equipment: The factory installs solar panels on its rooftop, generating enough electricity to power all its machinery and lighting systems. This not only reduces its carbon footprint but also lowers its energy costs over time.

-

Rainwater Harvesting System: The factory uses a rainwater harvesting system to collect and store rainwater for use in irrigation and other non-potable purposes. This reduces the need for potable water and conserves water resources.

-

Waste-to-Energy (WTE) Process: The factory uses a WTE process to convert waste textile scraps into valuable fibers for use in new products. This not only reduces waste but also generates revenue through recycled materials.

-

Green Building Practices: The factory incorporates green building practices throughout its design, including using natural light, ventilation, and insulation materials to minimize energy consumption.

Conclusion: In conclusion, designing a modern textile factory requires careful consideration of various factors, including layout planning, energy efficiency, waste management, and safety measures. By incorporating innovative technologies and sustainable practices, you can create a textile factory that not only meets current standards but also sets new benchmarks in sustainability and efficiency. As the global textile industry continues to evolve, investing in these aspects of factory design will not only benefit your business but also contribute to a healthier planet.

纺织品厂房设计概述

随着现代工业的快速发展,纺织品行业的需求日益增长,纺织品厂房的设计也变得越来越重要,本篇纺织品厂房设计图纸旨在为相关行业提供参考和指导。

设计图纸内容

厂房布局

厂房布局应考虑生产流程、人员流动、物流运输等因素,本设计图纸展示了厂房的基本布局,包括生产车间、辅助设施、办公区域等。

厂房布局图:

| 区域 | 功能 | 描述 |

|---|---|---|

| 生产车间 | 主要进行纺织品生产,包括织造、染整、印花等工序 | 宽敞明亮的生产车间,设有先进的生产设备和技术 |

| 辅助设施 | 如仓库、检验室、办公区等 | 提供必要的辅助设施,满足生产需求 |

| 办公区域 | 提供办公空间,方便员工和管理人员工作 | 设有舒适的办公环境,提供现代化的办公设施 |

材料选择与工艺流程

在材料选择方面,厂房应考虑使用环保、可持续的材料,工艺流程应符合现代纺织品的生产要求,本设计图纸展示了材料选择和工艺流程的具体内容。

材料选择与工艺流程图:

| 材料选择 | 描述 | 示例工艺流程 |

|---|---|---|

| 主要材料 | 如棉纱、涤纶纤维等环保材料 | 织造工序:原料投入→织布→染色→印花等 |

| 辅助材料 | 如染料、助剂等 | 生产过程中的必要辅助材料,确保产品质量和效率 |

| 工艺流程优化建议 | 根据市场需求和产品特点进行优化,提高生产效率和产品质量 | 采用自动化设备提高生产效率,优化工艺流程,减少浪费和环境污染 |

案例说明

为了更好地展示纺织品厂房设计的实际应用,我们以一个具体的案例进行说明,该案例是一家大型纺织品厂区的设计图纸,具有较高的参考价值。

案例名称:某纺织品厂区设计图纸

厂房布局与材料选择:

该纺织品厂区采用了先进的生产线布局,充分利用空间资源,厂房内使用了环保、可持续的材料,如天然纤维和再生材料,该厂区注重节能减排,采用了先进的节能技术和环保设备。

工艺流程与技术创新:

该厂区采用了先进的生产工艺流程,包括自动化织造、智能染色和印花技术,该厂区还注重技术创新,采用了智能化管理系统和数字化生产技术,提高了生产效率和产品质量,该厂区还注重员工培训和技能提升,为员工提供了良好的工作环境和发展机会。

英文表格补充说明

以下是英文表格补充说明部分:

表格1:纺织品厂房设计图纸示例

| 项目 | 描述 | 数据来源或参考标准 |

|---|---|---|

| 设计图纸标题 | Textile Plant Design Drawings for Fabric Workshop | 根据实际设计图纸内容制作 |

| 厂房布局图 | Layout of Textile Plant Building | 根据实际设计图纸展示的厂房布局图进行描述 |

| 材料选择示例 | Example of Material Selection for Textile Plant Building | 根据实际案例中的材料选择进行描述 |

| 工艺流程示例 | Example of Process Flow for Textile Plant Production | 根据实际案例中的工艺流程进行描述,并添加具体工艺流程图例和参数数据来源或参考标准 |

| 设计亮点总结 | Design Highlights Summary | 对设计图纸的主要内容进行总结和概括,便于理解和参考 |

本篇纺织品厂房设计图纸旨在为相关行业提供参考和指导,通过详细的设计图纸内容和案例说明,我们可以更好地了解纺织品厂房设计的实际应用和要求,我们也可以根据实际情况进行适当的调整和完善,以满足不同行业的需求。

Articles related to the knowledge points of this article:

The Address of the Tri-City Textile Wholesale Market

在商丘纺织品一条街的被子批发市场中,我们深入探索了各种纺织品和被子的种类与品质。今天,让我们一同走进这个充满生活气息的市场,感受其中的温暖与舒适

Strategic Approaches to Sustaining Success in the Textile Industry