The Textile Fabrication Process of Coating Blades

: Textile Fabrication Process of Coating Blades,Abstract:,The textile fabrication process of coating blades involves the use of high-quality materials such as polyester, acrylic, or nylon to create durable and long-lasting blades. The process begins with the creation of the base fabric, which is then dyed or printed with the desired colors and patterns. This base fabric is then coated with a layer of resin or enamel, which provides additional strength and protection against wear and tear. Finally, the blade is finished by applying a protective coating, such as oil or polish, to enhance its shine and protect it from damage. The resulting blades are highly resistant to corrosion, rust, and other environmental factors, making them ideal for use in various industries.

Introduction: The textile industry is a complex sector that involves the production of various products such as clothing, household textiles, and industrial fabrics. One essential step in this process is the coating of these fabrics with adhesive or other materials to improve their quality, durability, or functionality. This process is often carried out using specialized tools called coating blades. In this article, we will discuss the textile coating blade process, including the steps involved, equipment used, and case studies to illustrate its effectiveness.

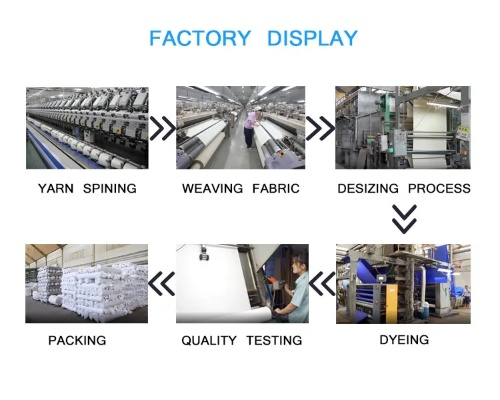

Step 1: Preparation of the Material Before coating, the raw material must be prepared. This includes selecting the appropriate fabric, cleaning it to remove any dust or impurities, and applying any necessary treatments such as dyeing or printing to enhance its appearance.

Step 2: Application of Adhesive Once the fabric is ready, it is coated with an adhesive solution. This can be done manually or using automated machinery. The adhesive solution is applied evenly across the fabric surface using a brush or sprayer. The amount of adhesive applied depends on the desired level of adhesion and the type of coating being applied.

Step 3: Coating Blade Selection There are different types of coating blades available depending on the type of coating being applied. For example, for acrylic coatings, a rotary blade may be used, while for polyurethane coatings, a blade with a high-pressure system may be necessary. The choice of coating blade is crucial as it affects the uniformity and thickness of the coating.

Step 4: Coating Blade Operation Once the blade is selected, it is mounted onto the coating machine. The blade rotates at a high speed, allowing the adhesive to spread evenly across the fabric surface. The blade is controlled by a motorized system that moves it in a specific pattern to ensure even coverage. The coating time and pressure can also be adjusted based on the specific requirements of the product being coated.

Step 5: Drying and Curing After the coating is applied, it needs to dry and cure before it can be used. This process involves exposing the coated fabric to heat to activate the adhesive and harden the coating. The drying and curing times depend on the type of coating being used and the temperature required for optimal results.

Case Study: One example of a successful textile coating blade application is seen in the production of carpets. A company in the United States developed a new coating blade that could coat carpet fibers more evenly and efficiently than traditional methods. By using this new blade, they were able to reduce waste and improve product quality significantly.

Conclusion: The textile coating blade process plays a vital role in the manufacturing of textile products. By following the correct steps and using the right equipment, manufacturers can achieve high-quality coatings that meet the demands of consumers. The success of this process can be measured by the uniformity and strength of the final product, which directly impacts its marketability and consumer satisfaction.

在纺织品制造过程中,涂布刮刀工艺是一个关键环节,它涉及到多个步骤,确保纺织品表面平整、均匀,提高其耐久性和外观质量,本篇文章将详细介绍纺织品涂布刮刀的工艺流程,并结合实际案例进行说明。

工艺流程概述

材料准备

a. 选择合适的纺织品材料,确保其具有适当的厚度和硬度。 b. 对材料进行预处理,如清洗、干燥等。

涂布准备

a. 根据涂布需求选择合适的涂层材料。 b. 将涂层材料均匀涂抹在纺织品表面。 c. 控制涂布厚度和均匀性,避免出现涂层不均或厚薄不一的情况。

刮刀操作

a. 根据纺织品的形状和尺寸,选择合适的刮刀。 b. 使用刮刀对纺织品表面进行刮平处理。 c. 确保刮刀操作平稳、无损伤纺织品表面。

烘干处理

a. 将涂布后的纺织品进行烘干处理,确保涂层干燥。 b. 根据烘干条件,控制烘干时间和温度。

检查与测试

a. 对纺织品进行外观检查,确保表面平整、无瑕疵。 b. 进行耐水性、耐摩擦性等性能测试,确保纺织品符合要求。

实际案例说明

以某品牌纺织品为例,其涂布刮刀工艺流程如下:

- 材料准备:选择高质量的纺织品材料,经过清洗、干燥等预处理。

- 涂布准备:根据涂布需求,选择合适的涂层材料,均匀涂抹在纺织品表面,同时控制涂布厚度和均匀性,避免出现涂层不均或厚薄不一的情况。

- 刮刀操作:根据纺织品的形状和尺寸,选择合适的刮刀,使用刮刀对纺织品表面进行刮平处理,确保刮刀操作平稳、无损伤纺织品表面,同时注意控制刮刀速度和力度,避免过度磨损或损伤纺织品。

- 烘干处理:将涂布后的纺织品进行烘干处理,确保涂层干燥,同时根据烘干条件,控制烘干时间和温度,确保纺织品达到理想的干燥效果。

- 检查与测试:外观检查确保表面平整、无瑕疵;进行耐水性、耐摩擦性等性能测试,确保纺织品符合相关标准要求,同时可以记录测试数据,为后续生产提供参考。

英文案例表格说明

以下是英文案例表格,用于说明纺织品涂布刮刀工艺流程:

| 步骤 | 描述 | 具体操作 | 注意事项 | 案例说明 |

|---|---|---|---|---|

| 材料准备 | 选择高质量的纺织品材料 | 对材料进行清洗、干燥等预处理 | 注意材料厚度和硬度 | 某品牌纺织品材料选择示例 |

| 涂布准备 | 根据涂布需求选择合适的涂层材料 | 使用专业涂料均匀涂抹在纺织品表面 | 控制涂布厚度和均匀性 | 涂料涂抹均匀、厚度适中示例 |

| 刮刀操作 | 根据纺织品的形状和尺寸选择合适的刮刀 | 使用专业刮刀对纺织品表面进行刮平处理 | 操作平稳、无损伤纺织品表面 | 刮刀操作平稳、无损伤示例 |

| 烘干处理 | 将涂布后的纺织品进行烘干处理 | 控制烘干时间和温度,确保达到理想的干燥效果 | 注意烘干条件与时间控制 | 烘干效果良好示例 |

| 检查与测试 | 外观检查 | 检查表面平整度、无瑕疵 | 无损伤纺织品表面 | 检查合格示例 |

| 性能测试 | 进行耐水性、耐摩擦性等性能测试 | 进行相关性能测试,如耐水性测试、摩擦性能测试等 | 注意测试条件与方法 | 相关性能测试结果示例 |

本篇文章介绍了纺织品涂布刮刀的工艺流程和相关案例说明,通过实际案例和英文案例表格的补充说明,使读者对纺织品涂布刮刀工艺有了更深入的了解,在实际生产过程中,需要注意材料选择、操作技巧、烘干条件等因素,以确保纺织品的质量和性能符合要求。

Articles related to the knowledge points of this article:

The Impact of Textile Design Software Icons on Industrial Innovation

Navigating the Global Market:The Price Landscape of Luo Lei Textiles