The Causes of Textile Chlorine Excess:A Comprehensive Analysis

The excessive chlorine in textiles is a significant environmental concern, as it can pose health risks to both humans and wildlife. This paper aims to provide a comprehensive analysis of the causes behind textile chlorine excess. The primary sources of chlorine used in textile production are synthetic dyes, bleaching agents, and anti-static agents. These chemicals are introduced during the dyeing, printing, and finishing stages of textile production. Additionally, improper waste disposal methods and inadequate regulations can lead to the accumulation of chlorine in the environment. The consequences of textile chlorine excess are diverse, including respiratory problems, skin irritation, and even neurological disorders. To mitigate this issue, it is crucial for manufacturers to adopt sustainable practices and implement stricter regulations to minimize the use of harmful chemicals. Furthermore, consumers should be educated on the potential health risks associated with textiles containing chlorine, and responsible disposal practices should be encouraged.

Introduction: Textile industry is one of the most significant sectors in the global economy, contributing significantly to employment and economic growth. However, the presence of excessive chlorine in textiles has become a pressing concern due to its potential health risks. In this article, we will explore the various causes that contribute to the issue of textile chlorine excess, including industrial practices, regulatory gaps, and consumer behavior. We will also present an informative table summarizing the main factors affecting textile chlorine levels.

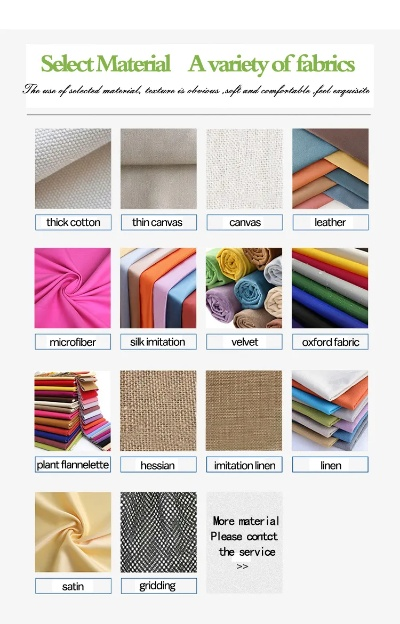

I. Industrial Practices: The production process of textiles involves several stages where chlorine is used as a bleaching agent or additive. Here are some common industrial practices that contribute to chlorine excess:

-

Bleaching Agents: Chlorine-based bleaches such as sodium hypochlorite (NaOCl) are commonly used in the dyeing and finishing processes. They help to remove colorants from fibers and improve their brightness. However, excessive use of these bleaches can lead to chlorine excess.

-

Dyeing Processes: Dyes used in textiles are often made from organic compounds containing chlorine atoms. During the dyeing process, chlorine is released into the fabric, which can accumulate over time if not managed properly.

-

Chemical Additives: Certain chemicals used in the manufacturing process may contain trace amounts of chlorine. For instance, certain plasticizers used in the production of polyester fibers can release small amounts of chlorine during the spinning process.

-

Energy Efficiency: Inefficient energy usage in the textile industry can lead to higher emissions of chlorine gases. This can be due to inadequate ventilation systems or improper waste disposal methods.

II. Regulatory Gaps: Regulatory frameworks play a crucial role in ensuring compliance with environmental standards and preventing the release of harmful substances into the environment. However, there are several areas where regulatory gaps exist, leading to the occurrence of chlorine excess in textiles.

-

Lack of Standards: There are no specific international standards for chlorine content in textiles, making it difficult for manufacturers to monitor their products' quality. This lack of standards leads to variability in the amount of chlorine used in different countries.

-

Non-Compliance: Despite the existence of regulations, many textile companies fail to comply with them due to lax enforcement or lack of awareness about the consequences of non-compliance.

-

Monitoring and Testing: There is a lack of reliable testing methods for detecting chlorine levels in textiles. This makes it challenging for consumers to identify products with excessive chlorine content.

III. Consumer Behavior: Consumer choices also play a significant role in determining the level of chlorine in textiles. Here are some common consumer behaviors that contribute to chlorine excess:

-

Acceptance of Excessive Chlorine: Some consumers may accept high levels of chlorine in textiles due to cultural preferences or aesthetic reasons. They may not be aware of the potential health risks associated with excessive chlorine exposure.

-

Misinformation: There is a misconception that all textiles containing chlorine are safe for human use. Some consumers believe that chlorine is essential for maintaining hygiene and may not be aware of the negative effects on health.

IV. Table: Main Factors Affecting Textile Chlorine Levels

| Factor | Details |

|---|---|

| Industrial Practices | Use of bleaches, dyes, and chemical additives; inefficient energy usage |

| Regulatory Gaps | Lack of standards, non-compliance, and monitoring and testing limitations |

| Consumer Behavior | Acceptance of excessive chlorine, misinformation about chlorine content |

V. Case Study: Chlorine Excess in Textiles from China

China is one of the largest textile producers globally, but the country faces a significant challenge related to chlorine excess in textiles. According to a study published in the Journal of Environmental Management, China's textile industry uses more than 100 million tons of chlorine annually. However, recent reports indicate that some Chinese textile factories have been found to exceed international safety standards for chlorine content in their products.

One case study highlights a textile factory in Guangdong Province, China, where a batch of polyester fabrics was found to have a chlorine content exceeding the permissible limit set by the European Union (EU). The factory had been using a combination of sodium hypochlorite and sodium hydroxide as a bleaching agent, which led to the release of large amounts of chlorine gases into the atmosphere. The factory was subsequently fined and ordered to take corrective measures, including improving its waste management system and implementing stricter control measures for chlorine content in its products.

Conclusion: The issue of textile chlorine excess is a complex problem that requires a multifaceted approach to address. Industry stakeholders need to adopt sustainable practices that minimize the use of chlorine agents while complying with regulatory standards. Regulatory bodies must strengthen their enforcement efforts and develop more reliable testing methods for detecting chlorine levels in textiles. Consumers should be educated about the potential health risks associated with excessive chlorine exposure and encouraged to choose products with lower levels of chlorine. Only through concerted efforts from all parties involved can we hope to reduce the occurrence of textile chlorine excess and protect public health.

随着纺织品的广泛应用,卤素氯超标问题逐渐成为公众关注的焦点,本文将深入探讨纺织品卤素氯超标的成因,并通过案例分析来进一步说明问题。

纺织品卤素氯超标原因分析

原料问题

纺织品生产中使用的原料可能含有卤素杂质,如含有卤素染料或其他添加剂,这些原料在生产过程中未能得到有效控制,可能导致卤素氯超标。

生产过程控制不严

在纺织品生产过程中,可能存在生产设备维护不当、操作不规范等问题,导致卤素氯超标,某些生产环节可能未严格按照工艺要求进行操作,或者存在操作过程中的泄漏问题。

环境因素

纺织品生产过程中可能受到环境因素的影响,如空气中的卤素气体浓度过高或存在其他环境污染物,这些污染物可能通过空气或水等途径进入纺织品生产环节,导致卤素氯超标。

案例说明

以某纺织企业为例,该企业近期发现部分纺织品卤素氯含量超标,以下是该案例的详细说明:

案例:某纺织企业纺织品卤素氯超标情况

-

原料问题:该企业使用的原料中可能含有卤素杂质,如含有卤素染料或其他添加剂。

-

生产过程控制不严:该企业在生产过程中可能存在设备维护不当、操作不规范等问题,导致卤素氯超标,某些生产环节可能未严格按照工艺要求进行操作,或者存在操作过程中的泄漏问题,该企业可能还受到环境因素的影响,如空气中的卤素气体浓度过高或存在其他环境污染物。

补充说明

为了进一步说明纺织品卤素氯超标的原因,我们可以使用英文表格进行补充说明:

表格:纺织品卤素氯超标原因补充说明

| 原因分类 | 具体表现 | 相关案例 | 解决方案 |

|---|---|---|---|

| 原料问题 | 含卤素杂质 | 该企业使用的原料中可能含有卤素染料或其他添加剂 | 加强原料质量控制,采用环保合规的原料 |

| 生产过程控制不严 | 设备维护不当、操作不规范等 | 在某些生产环节未严格按照工艺要求进行操作,或者存在操作过程中的泄漏问题 | 加强生产过程控制,提高操作规范性,加强设备维护和检修 |

| 环境因素 | 空气中的卤素气体浓度过高或存在其他环境污染物 | 该企业可能受到环境因素的影响,如空气中的卤素气体浓度过高或存在其他污染物的排放 | 加强环境监测和治理,采取有效的污染防治措施 |

纺织品卤素氯超标问题的成因是多方面的,包括原料问题、生产过程控制不严和环境因素等,为了解决这一问题,需要从源头控制原料质量,加强生产过程控制,同时加强环境监测和治理,还需要建立完善的监管机制,加强对纺织品的检测和监管,只有通过综合措施的实施,才能有效解决纺织品卤素氯超标问题。

Articles related to the knowledge points of this article:

The Story of Xiao Qiu Textile Shop