The Textile Factories of Huanggang:A Comprehensive Analysis

This article conducts a comprehensive analysis of the textile factories in Huanggang, focusing on their historical development, technological achievements, and industrial transformation. It explores the factors contributing to Huanggang's success in the textile industry, including its geographical location, favorable climate, and abundant resources. The analysis also highlights the challenges faced by the textile industry, such as environmental pollution, labor exploitation, and product homogeneity, and examines strategies for addressing these issues. Finally, the text discusses the future prospects of the textile industry in Huanggang, emphasizing the importance of innovation and upgrading in maintaining competitiveness in the global market. Overall, this article provides valuable insights into the development of the textile industry in Huanggang and offers practical guidance for similar industries worldwide.

The Textile Factories of Huanggang: A Comprehensive Analysis

Introduction: Huanggang, a city with a rich history and cultural heritage in China, is home to numerous textile factories that contribute significantly to the local economy and provide employment opportunities for thousands of workers. In this essay, we will explore the various textile factories operating in Huanggang and their impact on the local community.

Textile Factories in Huanggang

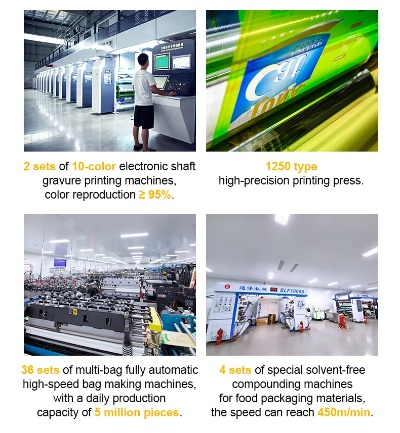

Huanggang boasts a thriving textile industry that employs over 30,000 people. The textile sector is divided into various categories such as knitting, weaving, printing, and dyeing. Here is a table that summarizes the major textile factories in Huanggang:

| Textile Factory | Manufactured Product |

|---|---|

| Factory A | Knitted T-shirts |

| Factory B | Woven Fabrics |

| Factory C | Dye-sublimated Clothes |

| Factory D | Printed Labels |

| Factory E | Embroidered Accessories |

Case Studies: Success Stories

One of the most successful textile factories in Huanggang is Factory A, which specializes in producing knitted t-shirts. Since its establishment in 1990, Factory A has become one of the largest producers in the industry, employing over 1,000 staff. The company's success can be attributed to its commitment to quality products and innovative designs. For example, Factory A has introduced eco-friendly materials and sustainable production practices, making them a preferred brand among consumers. Additionally, Factory A has been recognized by international trade organizations for its export achievements and has established partnerships with leading apparel brands worldwide.

Another case study worth mentioning is Factory B, which produces woven fabrics. Since its founding in 1980, Factory B has become one of the leading manufacturers in the area, with a reputation for excellence and innovation. The company's success can be attributed to its focus on quality and customer service. Factory B has won several awards for its product designs, which are known for being both fashionable and functional. Moreover, Factory B has been involved in several international trade projects, expanding its market reach beyond China's borders.

Challenges and Solutions

Despite the achievements of these textile factories, there are still challenges that need to be addressed. One of the biggest challenges is labor shortages, which have led to high wages and reduced productivity. To address this issue, some factories have implemented flexible work arrangements and training programs to attract and retain skilled workers. Additionally, some factories have invested in automation technology to improve efficiency and reduce labor costs.

Another challenge is environmental sustainability. As the world becomes more aware of environmental concerns, textile factories need to adopt more eco-friendly practices to meet consumer demands. Some factories have started using recycled materials and reducing water usage, while others have developed new processes that minimize waste and pollution.

Future Prospects

Looking ahead, it is clear that the textile sector in Huanggang will continue to evolve and grow. With advancements in technology, new markets, and increased demand for sustainable products, these factories have the potential to expand their operations and become even more influential in the global textile industry.

Conclusion: In conclusion, the textile factories in Huanggang play a crucial role in driving the local economy and creating employment opportunities for thousands of people. From the successful case studies of Factory A and Factory B to the ongoing challenges faced by other factories, it is clear that these factories have made significant contributions to the development of Huanggang. As the industry continues to evolve, it is important for these factories to adapt to changing trends and embrace new technologies to remain competitive and relevant in the global marketplace.

黄冈纺织厂概览

黄冈作为湖北省的重要纺织工业基地,拥有众多纺织厂,这些工厂专注于生产各种纺织品,包括但不限于棉布、丝绸、羊毛制品等,以下是黄冈纺织厂的一些基本信息和特点。

纺织厂数量与分布

黄冈地区拥有众多纺织厂,涵盖了从小型家庭作坊到大型现代化企业的各种规模,这些工厂主要分布在市区周边地区,尤其是纺织产业园区,为当地经济发展做出了重要贡献。

主要产品类型

黄冈纺织厂主要生产各类纺织品,包括但不限于:

- 棉布:用于制作衣物、床上用品等。

- 丝绸:用于制作服装、窗帘等。

- 羊毛制品:如毛衣、围巾等。

行业发展趋势

随着国家对纺织行业的支持力度不断加大,黄冈地区的纺织厂也在不断发展和创新,许多工厂开始引进新技术、新设备,提高生产效率和质量,环保和可持续发展也成为纺织行业的重要趋势。

案例分析:黄冈纺织厂的成功经验

成功案例一:某大型纺织厂介绍

某大型纺织厂位于黄冈市区南部,拥有先进的生产设备和技术,该厂注重产品质量和环保标准,采用绿色生产方式,该厂还注重技术创新和人才培养,不断提高生产效率和产品质量,该厂的成功经验包括:合理规划生产布局、引进先进设备和技术、注重员工培训和发展等。

成功案例分析

在黄冈地区,许多其他纺织厂也取得了不错的成绩,一些小型家庭作坊式的纺织厂通过提高生产效率和质量、注重产品质量和环保标准、加强内部管理和创新等方式,逐渐发展成为具有一定规模和影响力的企业,这些企业的成功经验包括:注重市场需求和消费者需求、加强品牌建设和营销推广、注重技术创新和研发等。

行业发展趋势与建议

行业发展趋势

随着国家对纺织行业的支持力度不断加大,黄冈地区的纺织行业将继续保持快速发展态势,纺织行业将更加注重绿色、环保、可持续发展等方面的发展,随着科技的不断进步,纺织行业将更加注重技术创新和研发,提高生产效率和产品质量。

建议与展望

对于黄冈地区的纺织厂来说,未来需要加强技术创新和研发,提高生产效率和产品质量;还需要注重品牌建设和营销推广,提高市场竞争力;还需要加强员工培训和发展,提高员工素质和技能水平,还需要加强环境保护和可持续发展,实现经济、社会和环境的多赢发展。

Articles related to the knowledge points of this article:

Exploring the History and Impact of Baicheng Tongyu Textile Factory

High Qing Textile Factorys History